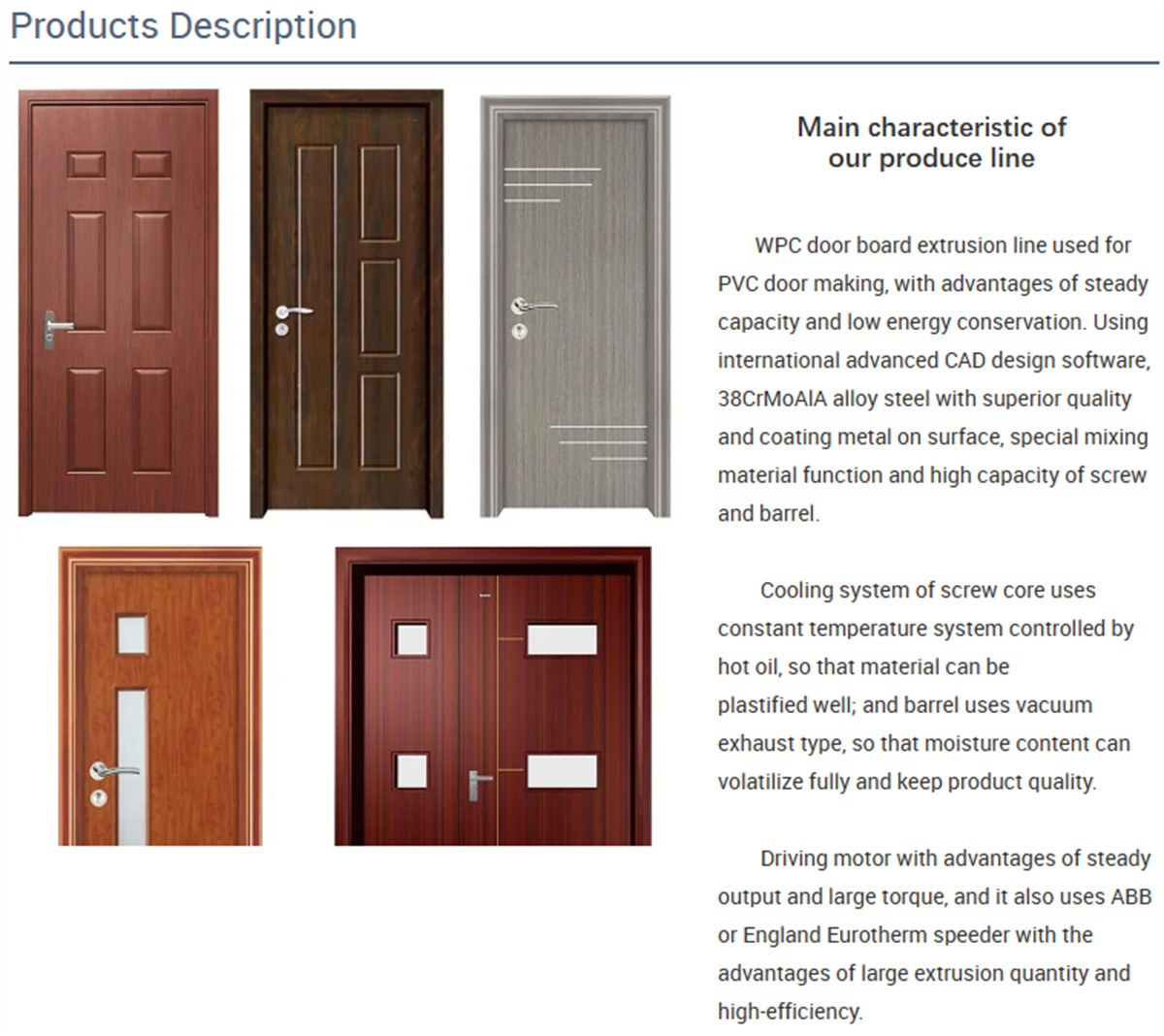

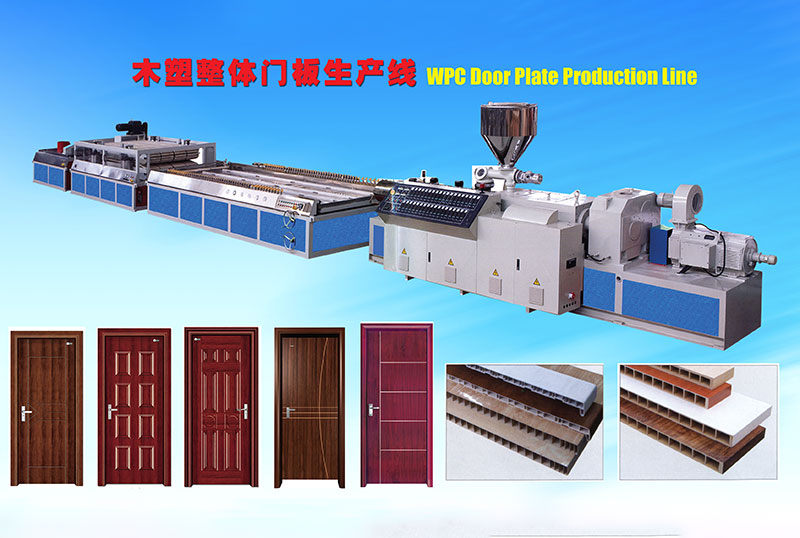

Wood Plastic WPC door board Production Line

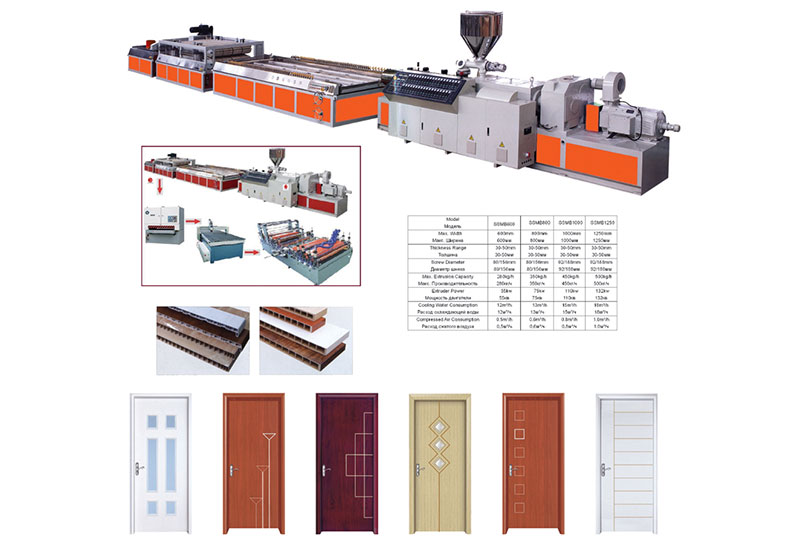

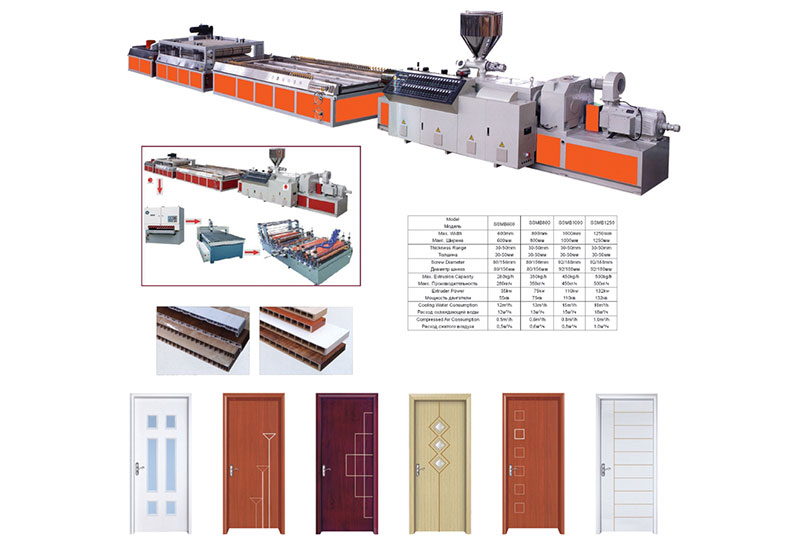

Main Machine Flow Chart

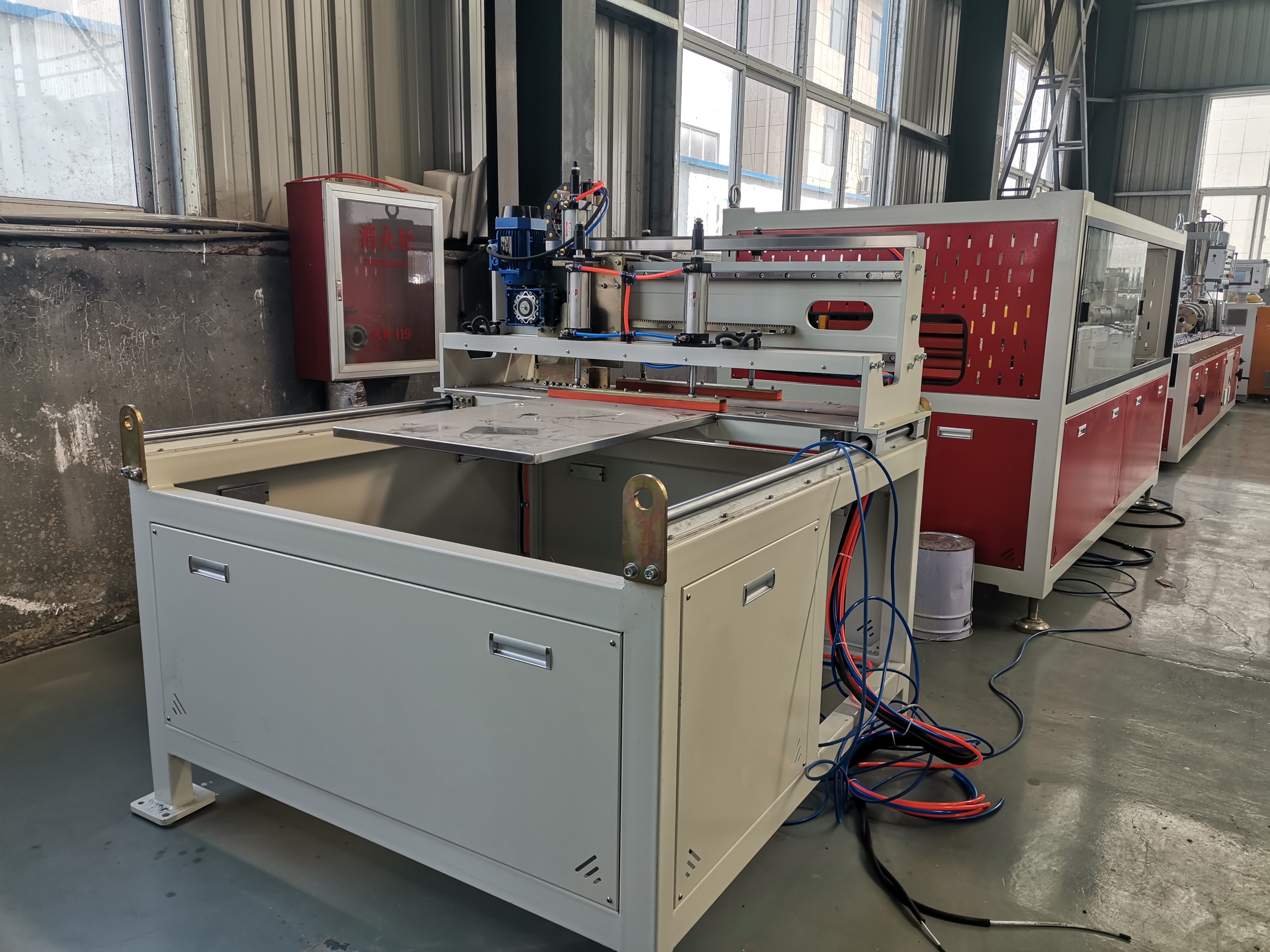

| No | Machine Name | Quantity |

| 1 | Screw Loader for Mixer | |

| 2 | SRL-Z serious High Speed Mixing Unit | |

| 3 | Screw Loader for Extruder | |

| 4 | SJSZ serious Conical Twin Screw Extruder | |

| 5 | Mold head+Calibration forming mold | |

| 6 | Vacuum Calibration Machine | |

| 7 | Traction Machine | |

| 8 | Cutting Machine | |

| 9 | Stacking Table |

|

Model |

SJSZ80/156 |

SJSZ92/188 |

|

Screw dia.(mm) |

Φ80/Φ156 |

Φ92/Φ188 |

|

Screw quantity(pcs) |

2 |

2 |

|

Screw speed(r/min) |

1-38 |

1-32.9 |

|

Main extruder power(kwh) |

55 |

90 |

|

Heating power (approx.)( kwh) |

36 |

78 |

|

Extrusion output(kg/h) |

350-450 |

500-600 |

Application

plastic composite plate/board Production Extruder Machine is mainly used for making PVC plastic profile with different section shape and height. the surface of PVC profile/panel can be treated by printing & coated with glossy oil, or by heat transfer printing, or by lamination, which can make good decoration effect for kitchen,toilet,balcony and so on.

Features

1.Healthy and environmentally friendly (lead free)

2.Light weight, easy for installation and maintenance.

3.No painting or varnishing,

4.Waterproof, fire retarding, wearing resistance, corrosion resistance, mildew proof and good insulation.

5.the panel can be further processed, like nailing, sawing, drilling and bonding with other PVC film, etc.