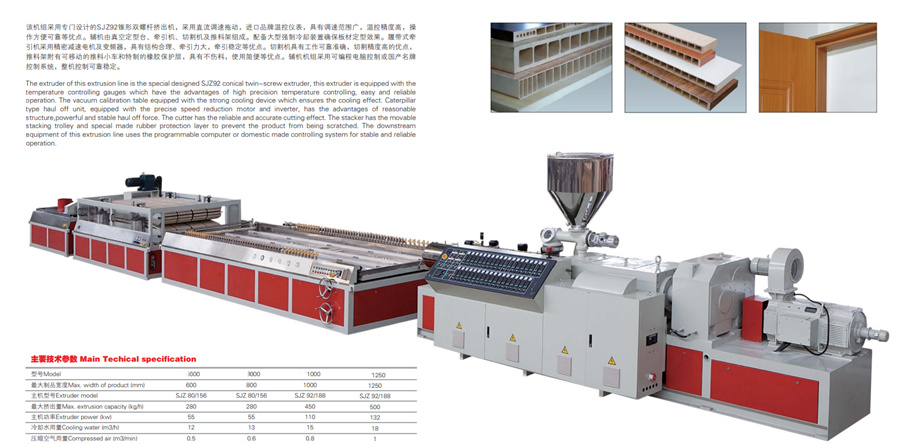

Wood Plastic Composite Profile Production Line

Specifications

|

Model |

SJSZ65/132 |

SJSZ80/156 |

|

Screw dia.(mm) |

Φ65/Φ132 |

Φ80/Φ156 |

|

Screw quantity(pcs) |

2 |

2 |

|

Screw speed(r/min) |

1-35 |

1-37 |

|

Main extruder power(kwh) |

37 |

55 |

|

Heating power (approx.)( kwh) |

24 |

36 |

|

Extrusion output(kg/h) |

250-300 |

350-400 |

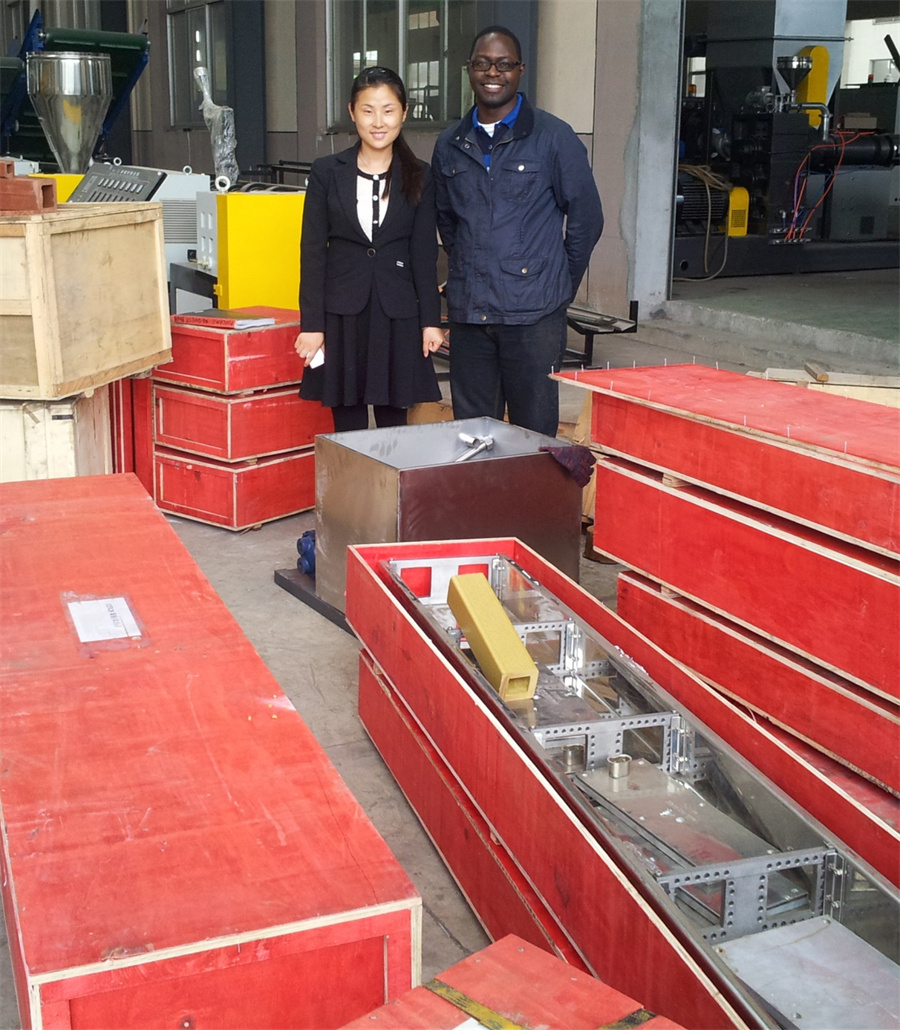

Cooperative Partner

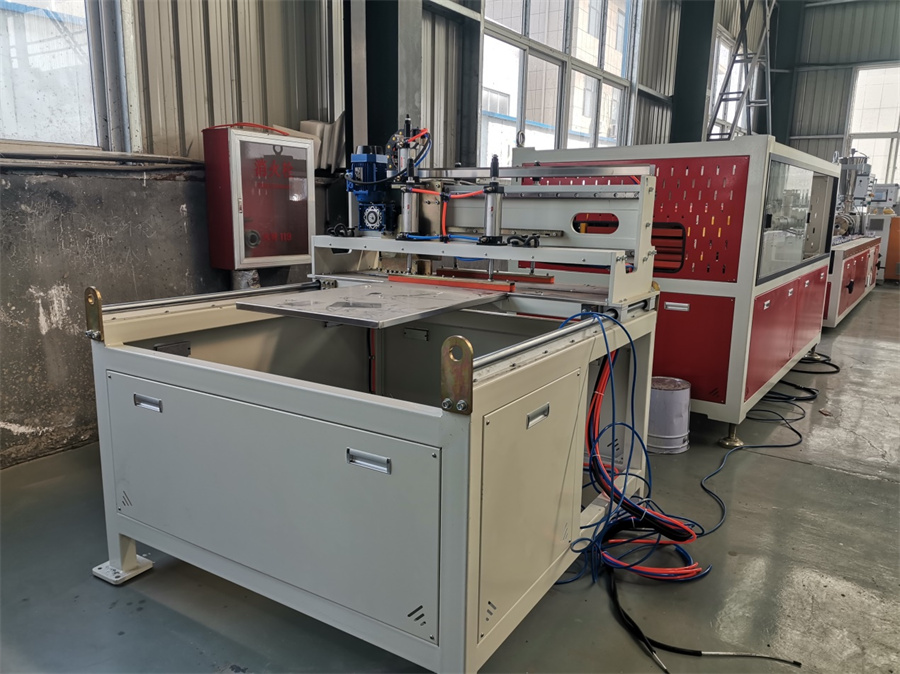

Technical Parameter

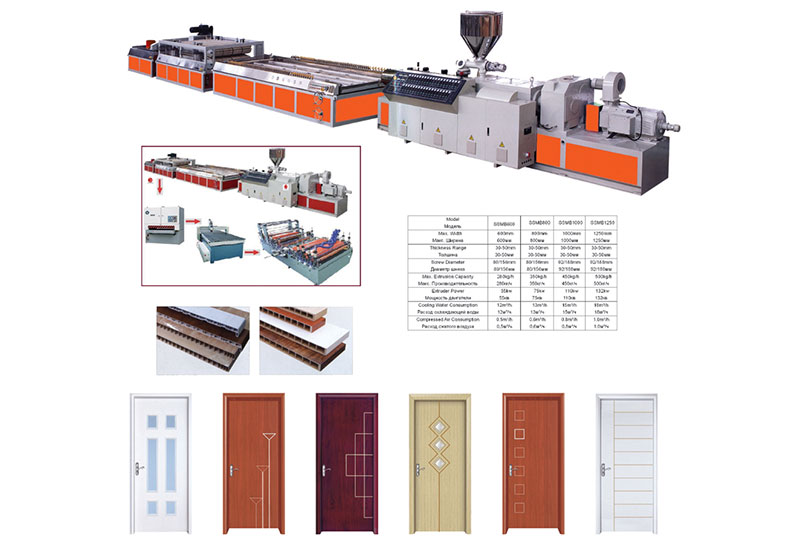

For production of soft PVC profile, rigid PVC profile, soft-hard co-extrusion profile,foam profile extrusion, multi layer co-extrusion etc.

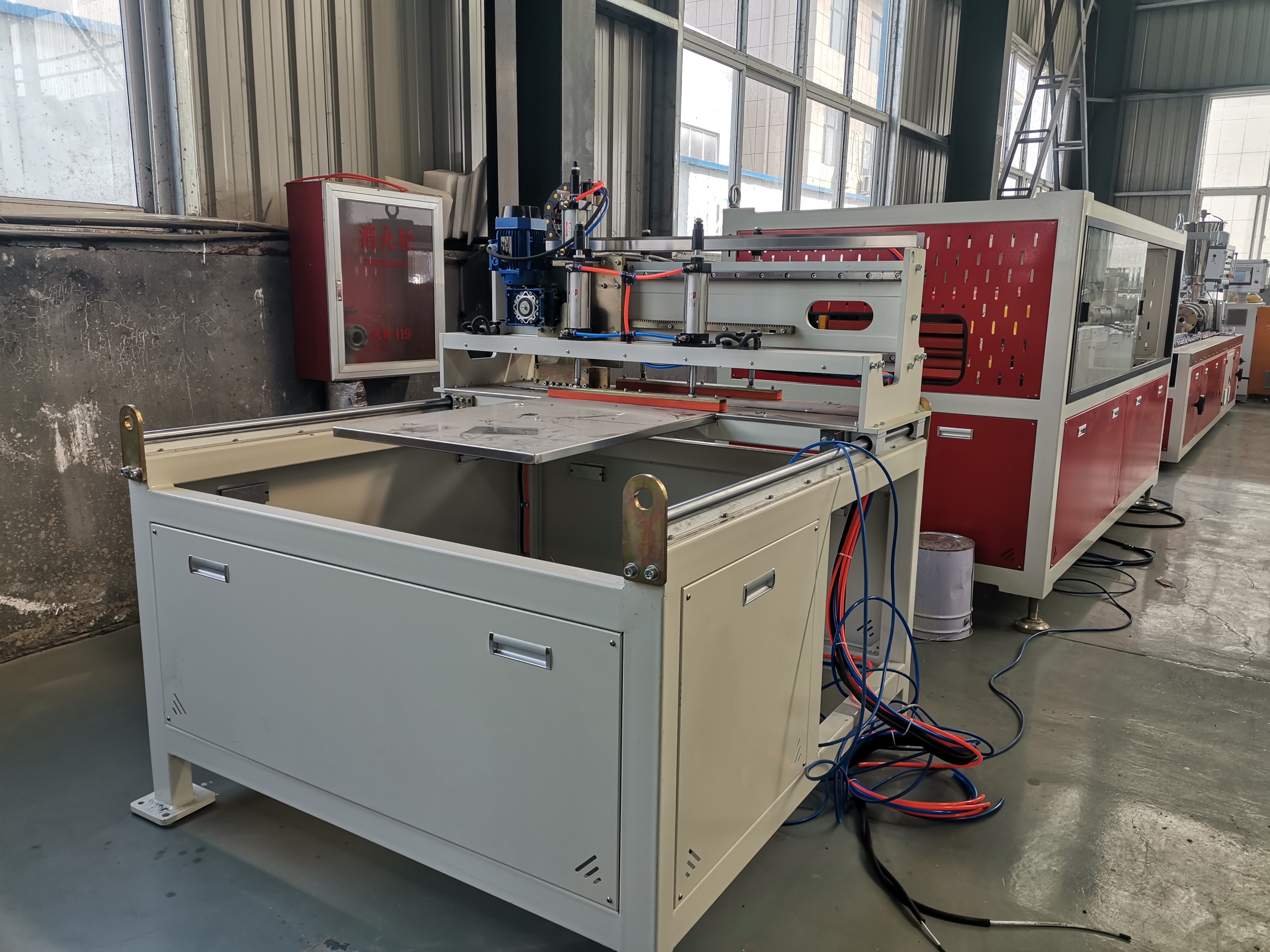

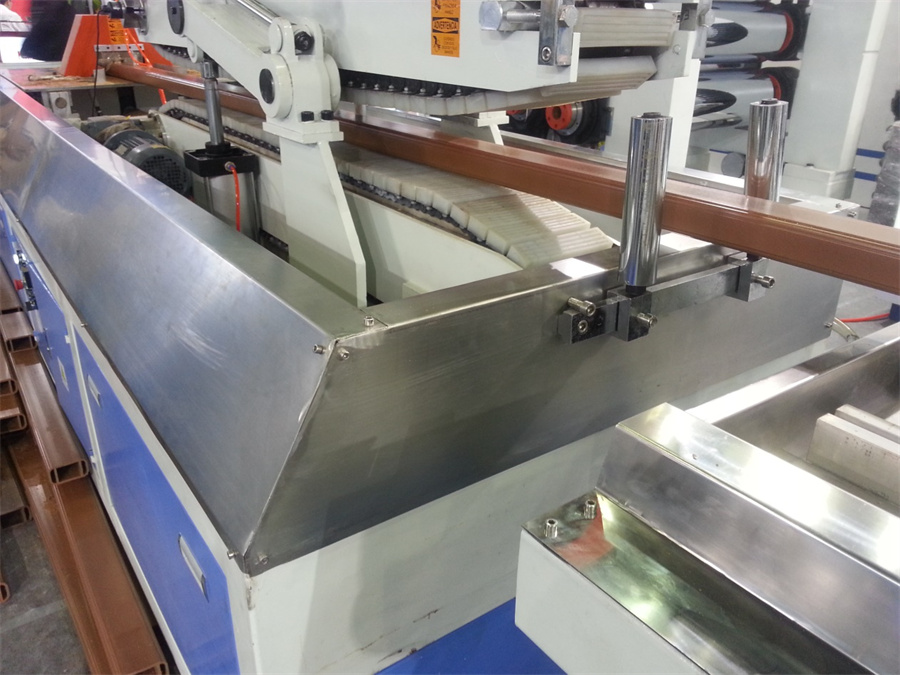

>>Process Flow: Screw Loader →cone / Twin Screw Extruder/Single screw extruder → Co-extrusion machine → Mould → Calibration Table → Haul-off & Cutter →Tripping Table → Final Product Inspecting & Packing

Die head

• 3Cr13/3Cr17 material;

•Complete set include extrusion die head, calibrator and cooling tank;

• Apply to soft PVC, rigid PVC, soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

Our Advantages

Affordable pvc wpc ceiling wall panel make manufacturing machine lines

(1)High shrink surface, smooth without gap when concatenated

(2)Fireproof, moisture-proof, mould-proof, waterproof, soundproof, sound-absorbing, light in weight and easy installation.

(3)For ceiling and wall decoration

(4)The variety of colors and patterns

FAQ

Q1:Are you a trading company or a manufactory?

A1:We are a manufactory, can give u best service.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 1 years guarantee . we will give u spare part free in 1 years.

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.