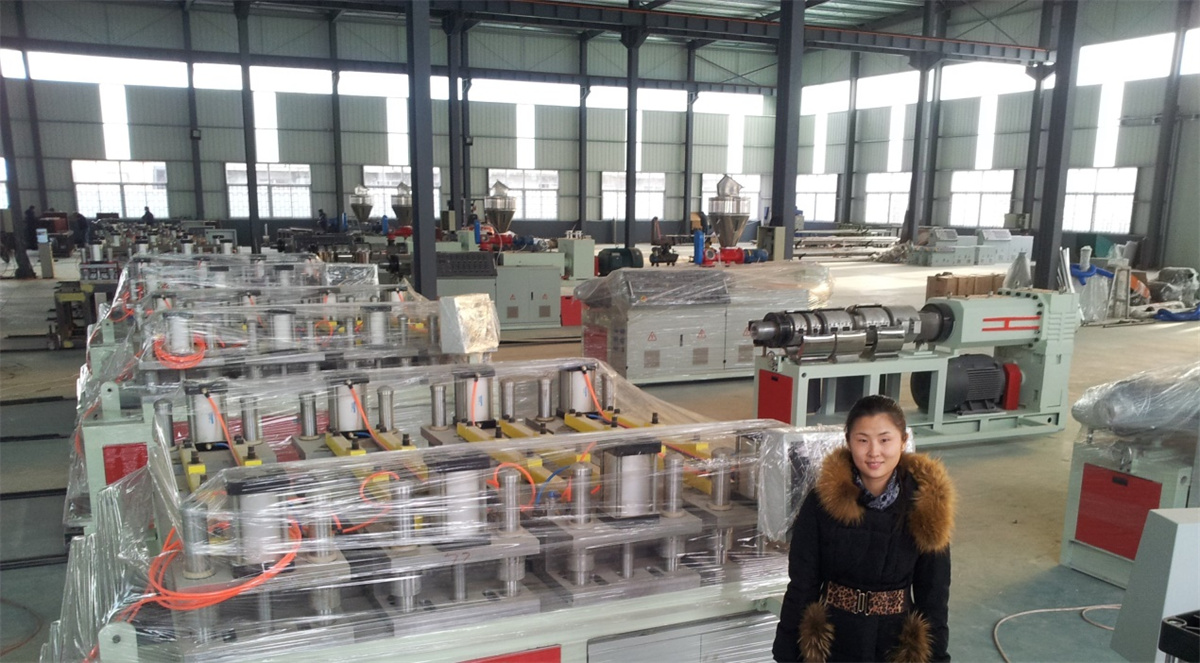

SJSZ80 PVC crust foamed sheet production line

Specifications

Output dimension of long life PVC foam board machine

|

Extruder Mold |

SJSZ-80/156 |

SJSZ -80/173 |

SJSZ -92/188 |

|

|

Output capacity |

kgs/h |

350 |

550 |

650 |

|

Output thickness |

mm |

3-25 |

3-30 |

3-30 |

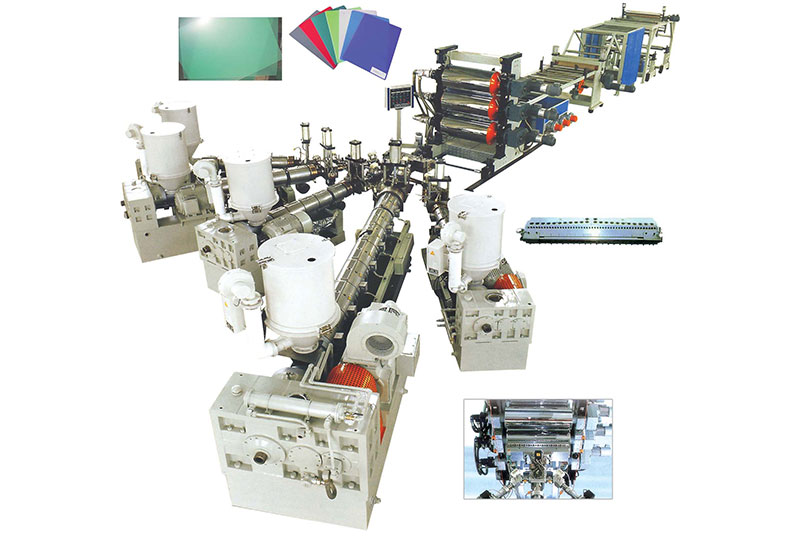

List of machines and advantages

|

NO. |

Name of machine |

Advantage of machine |

|

1 |

Automatic feed loader |

Fully automatic |

|

2 |

Conical Twin Screw extruder |

Inverted SIEMENS motor, famous brand gearbox and full set of SIEMENS electric control system,30% ENERGY SAVING, STABLE RUNNING, LONG SERVICE LIFE |

|

3 |

T-die |

Design by ourself with over 10 years manufacturing experience |

|

4 |

Calibrator |

100mm thickness mirror surface calibrator |

|

5 |

Cooling Bracket |

9 pcs stainless iron rollers |

|

6 |

Haul off machine |

8-12 pairs rubber surface rollers |

|

7 |

Transverse cutter |

|

|

8 |

Stacker/manipulator |

Automatic operation |

| Auxiliary machines(optional) | ||

|

1 |

Crusher |

For recycling unqualified board |

|

2 |

Grinder /Pulverizer |

For recycling unqualified board |

|

3 |

High-speed Heat/Cooling Mixer |

For mixing raw materials 500/1000 MODEL |

|

4 |

20P Chiller |

To supply cool water |

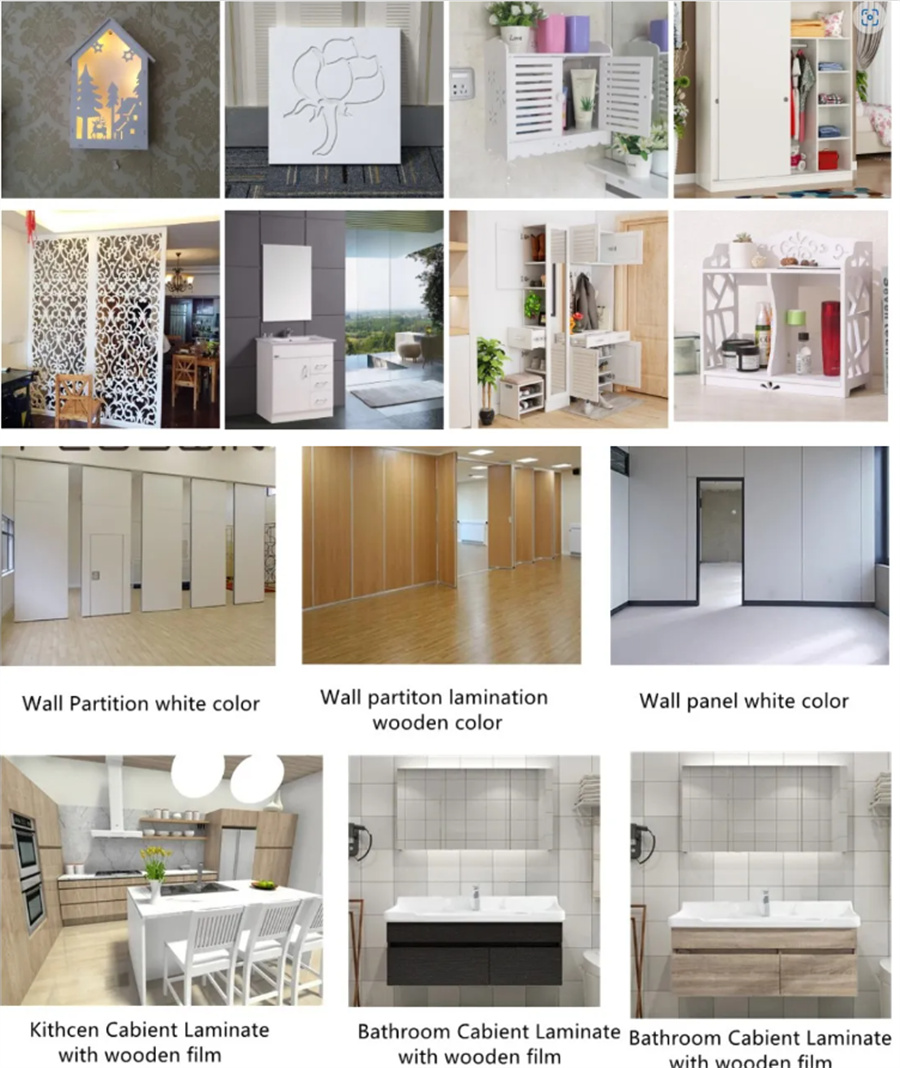

Application

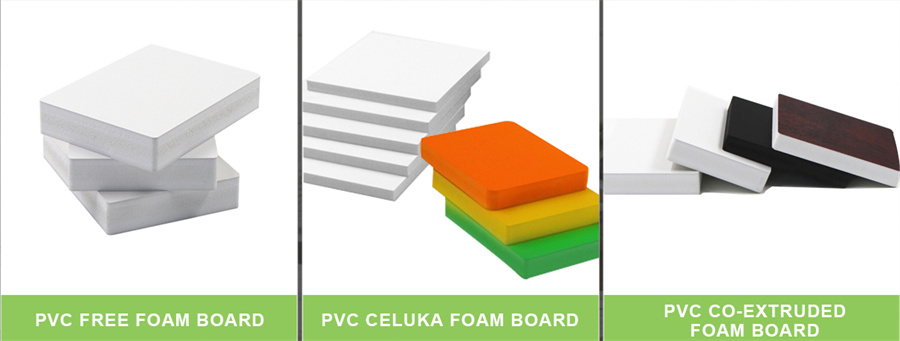

This equipment is mainly used for producing wood plastic foam board sheets.The line produced plates are applied in interior decoration,furniture,cabinets,sanitary wares,advertising boards,art materials,templates of construction and sound insulation,etc.The production is so widely used with enormous prospects.