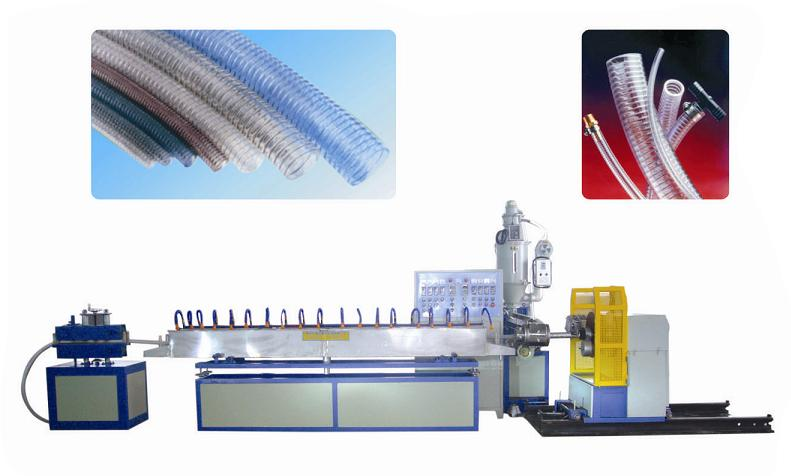

PVC spiral steel wire hose extrusion line

PVC spiral steel wire hose extrusion line

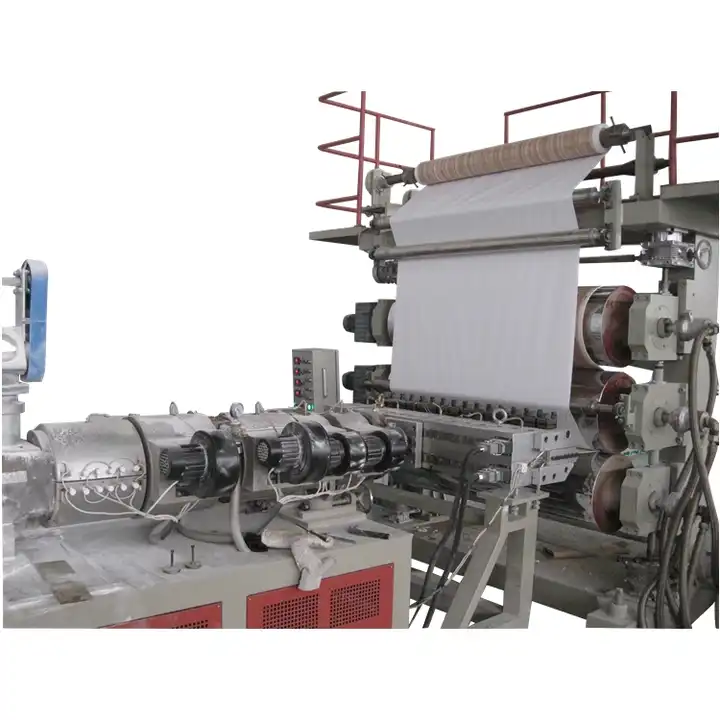

(Picture only for reference)

Summarize:

1、PVC hose: OD 16-50mm----(According to the buyer requirement)

2、Material:PVC and steel wire

4、Extrusion output: 25-50 Kg/h

3、Extruder: SJ65/28 × 1 set ; SJ25/25× 3 set

5、Extruder axis height:1000cm

6、Operation direction: from right to left

7、Industry power : 380V;50Hz;3phase

Specification of the production line

Process flow chart:

Spiral steel wire forming unit àextruderàCoextrusion-mouldàwater cooling tankàhaul offàwinder

A. SYSTEM CONFIGURATION OF THE PRODUCTION LINE

• 1 set of Spiral steel wire forming unit

• 1 set of single-Screw Extruder type SJ65/28

• 3 set of single screw extruder SJ25/25

• 1 set of Co-extrusion mould for three marking line

• 1 set of water cooling tank

• 1 set of hauling off machine

• 1 set of Manual winder

B. DETAIL TECHNICAL PARAMETERS OF THE CONFIGURATIONS ABOVE

1. Spiral steel wire forming unit

| No | Item | Remarks |

| 1 | Motor power |

3.7kw+1.5kw(totally two motor) |

| 2 | Speed control ways |

By frequency inverter ABB brand |

| 3 | Rotary speed | 320rpm |

| 4 | Suitable diameter range | 16-50mm |

2. single-Screw Extruder type SJ65/28

| unit | Specification | Remark |

| 1 | Screw diameter | 65mm |

| 2 | L/D | 28:1 |

| 3 | Material of screw | 38CrMoAl, nitrogen treated |

| 4 | Nitrogen depth | 0.5~0.6mm |

| 5 | Surface Hardness | (HV) 800~940 |

| 6 | Screw surface roughness | Ra≤0.8um |

| 7 | Material of Barrel | 38CrMoAl, nitrogen treated |

| 8 | Nitrogen depth | 0.5~0.7mm |

| 9 | Surface Hardness | (HV) >950 |

| 10 | Inner face roughness | Ra≤1.6um |

| 11 | Gearbox | Hard tooth face, Material 20CrMnTi |

| 12 | Main motor | 22KW –AC motor with Siemens brand |

| 13 | Heating power | 10kw |

| 14 | Heating zone | 4zone |

| 15 | Cooling ways for heater | By air blower (4air blower*0.37kw/set) |

| 16 | Material of heater | Aluminum cast heater |

| 17 | Speed adjusting mode | Frequency conversion |

| 18 | Frequency Converter | ABB Brand |

| 19 | Temp. Control meter | RKC of Japan |

| 20 | Motor of extruder | With power over-load protect system |

| 21 | The die-head of extruder | With pressure over load protect system |

3. Co-extruder SJ25/25

|

Item |

Description |

Unit |

SJ25/25 |

|

1 |

Diameter of the Screw |

mm |

25 |

|

2 |

Ratio of length to diameter |

|

25:1 |

|

3 |

Output |

Kg/h |

1.5-5 |

|

4 |

Rotation Speed of the Screw |

rev/min |

5-20 |

|

5 |

Material of the Screw barrel and the Screws |

|

38CrMoAlA |

|

6 |

Gear box |

|

Hard tooth face , low noise design |

|

7 |

Heating Capacity of the Screw barrel |

KW |

2.4 |

|

8 |

Heating areas of the barrel |

|

2 |

|

9 |

Main Motor Power |

Kw |

1.5–AC motor with Siemens brand |

|

10 |

Speed Adjusting Mode |

|

frequency conversion |

|

11 |

Cooling for barrel |

|

Air flow cooling, 2- areas |

|

12 |

Height of the Screw Axes |

mm |

1000 |

|

13 |

Temperature controller |

|

Brand: RKC, Japan |

|

14 |

Frequency Converter |

|

Brand: ABB, Japan |

|

15 |

Figure dimension |

mm |

1450×450×1500 |

|

16 |

Weight |

kg |

250 |

4. Co-extrusion Mould with three color

| No | Item | Remarks |

| 1 | material |

40Cr with good quality mould steel |

| 2 | Runner Surface treatment |

Chrome-plated and polished |

| 3 | Diameter size | According to the buyer |

| 4 | Wall thickness of hose | According to the buyer |

5. Water cooling tank

| No | Specification | |

| 1 | length | 3000mm |

| 2 | Material | Stainless steel 304 |

| 3 | Movement | It Can be moved forward and backward |

| 4 | Cooling type | Water Spray cooling |

| 5 | Water pump power | 0.75kw |

6. Hauling off machine

| No | Item | |

| 1 | Type | Two pedrails |

| 2 | Effective holding length | 1000mm |

| 3 | Power of motor | 3kw |

| 4 | Drawing speed | 0.1~15m/min |

| 5 | Speed governor | Variable frequency conversion;

ABB frequency inverter |

| 6 | Driving ways | By double belt |

7. Manual winder