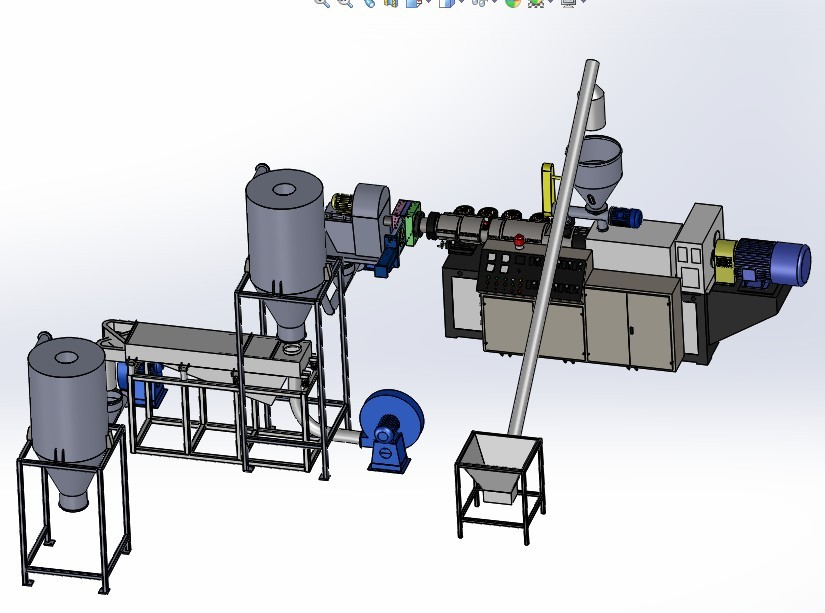

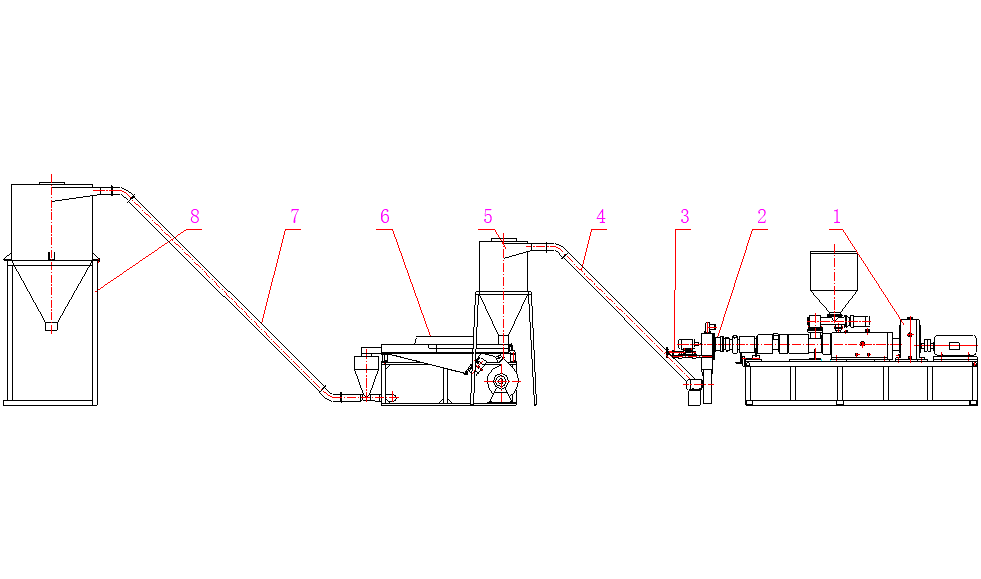

PVC Pelletizing Line (Capacity: 350-400kg/h)

Products Description

Part 1. Process flow of PVC pelletizing line

Feeder→Mixer →feeder→extruder→hot-face pelletizer→air blowing system→Silo→vibrator sieve→air blowing system→Silo

Part 2. Price list of 350-400kg/h PVC pelletizing line

|

No |

Name |

Quantity |

Unit price (USD) |

|

1 |

SRL-Z200/500 mixer group |

1set |

|

|

feeder for mixer |

1set |

||

|

2 |

Feeder for extruder |

1set |

|

|

3 |

SJSZ80/156 conical double screw extruder |

1set |

|

|

4 |

Pelletizer |

1set |

|

|

5 |

Air blowing system and air tube |

1set |

|

|

6 |

Silo |

1set |

|

|

7 |

Vibrator sieve |

1set |

|

|

8 |

Air blowing system and air tube |

1set |

|

|

9 |

Silo |

1set |

|

|

|

|||

Part 3. Technical parameter of each machine in PVC pelletizing line

1. SRL-Z200/500 hot and cooling mixer units

1. Application:

Mix raw material

2. Output: ≤350kg/hour

3. Equipment components:

① hot mixer

② cooling mixer

③ autoloader

4. Features:

Mechanical parts:

Pot body adopt SUS304 stainless steel which has very good smooth and rigid surface with features of wearable, corrosion resisting,heat resisting, no-stick with raw material

Hot mixer cover material adopt ZL102 casting aluminum with polished surface

Hot and cooling mixer open adopt cylinder pneumatic drive; the main shaft of hot and cold mixer adopt NSK brand which has features of reliable stable working performance.

Hot and cooling sealing adopt silicon rubber sealing with reliable sealing effect and not deformation even at high temperature.

Stirring paddle past dynamic balance testing which lower noise and improve lifespan

Electric parts:

Adopt intelligent RKC thermo control; Adopt famous brand motor

4. Parameter

| Item | Description | Unit | remarks |

| 1 | Transport tube diameter | mm | 102 |

| 2 | Charging motor power | KW | 1.5 |

| 3 | Charge capacity | Kg/h | 300 |

| 4 | Storage volume | kg | 150 |

| 5 | Material of storage hopper and tube | / | Stainless steel304 |

2. Feeder

| Item | Description | Unit | remarks |

|

|||

|

1 |

Rated Charge Capacity | Kg/h | 450 |

|

2 |

Max charge capacity | Kg/h | 450 |

|

3 |

Motor Power | KW | 1.5 |

|

4 |

Hopper volume | Kg | 120 |

|

5 |

Length | mm | 7000 |

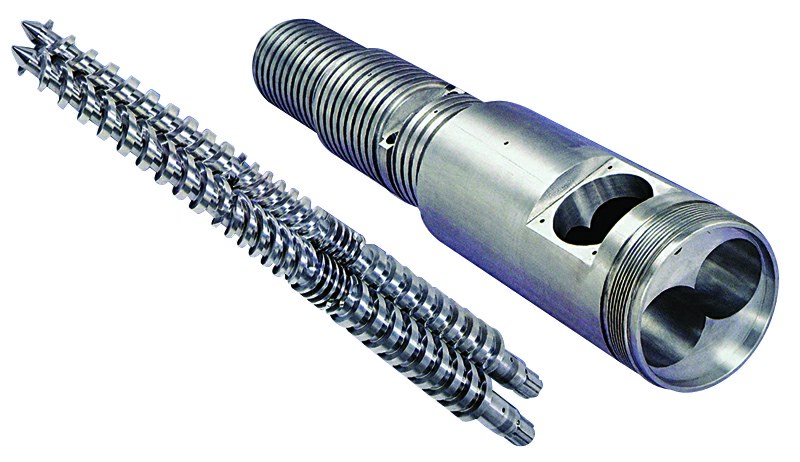

3. SJSZ80/156 conical double screw extruder

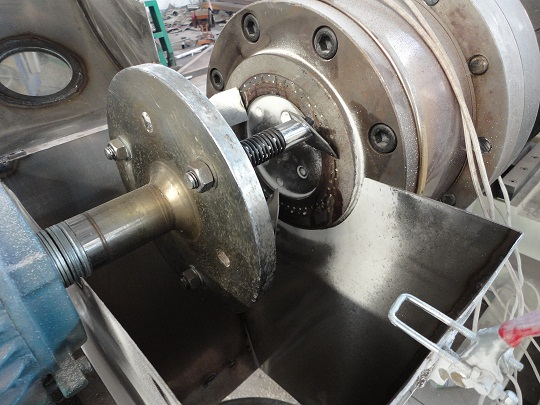

4. Hot-face pelletizer

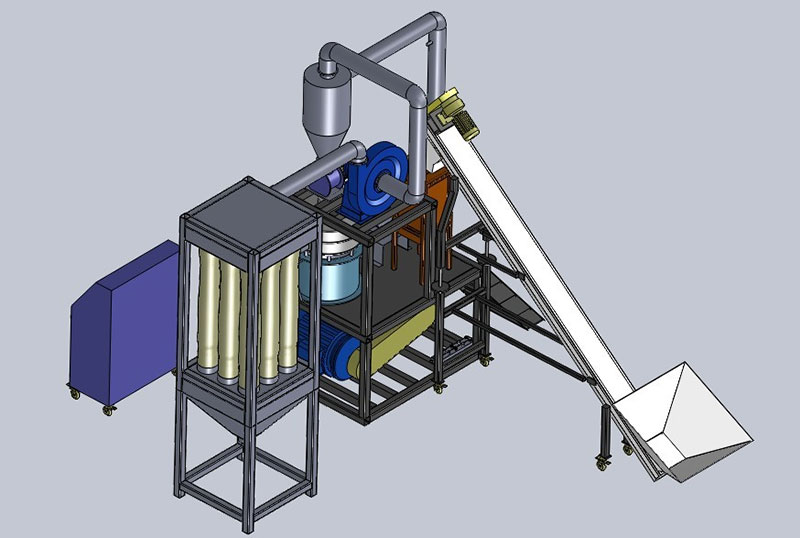

5. Air blowing system

| Item | Description | remarks |

|

1 |

Air blower | 4KW |

|

2 |

Diameter of the pipe | 114MM |

|

3 |

Material of the pipe | stainless steel 304 |

|

4 |

The air tube with double layer ,it is water jacket design for this tube | |

6. Silo

| Item | Description | remarks |

|

1 |

Volume: | 800L |

|

2 |

The material of storage | stainless steel 304 |

|

3 |

The silo body in two layer, with water jacket cooling between two layer. | |

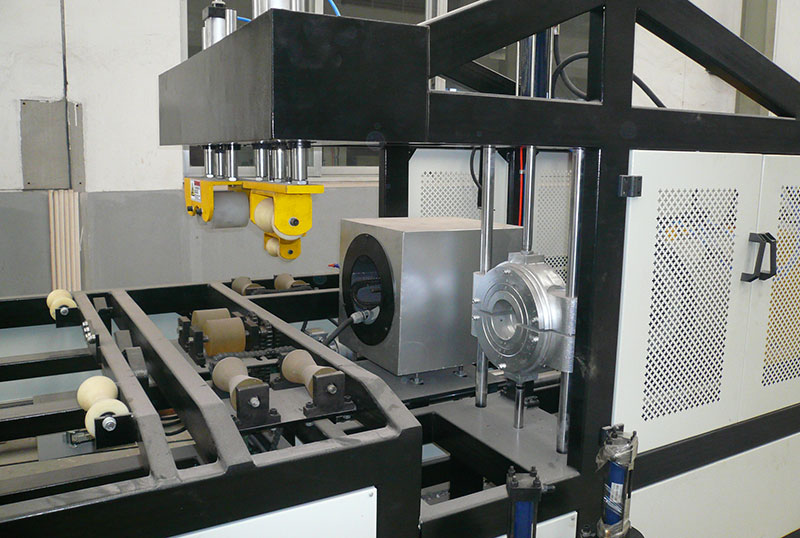

7.Vibrator sieve

| Item | Description | remarks |

|

1 |

Power of vibrating motor | 0.4kw |

|

2 |

Quantity of vibrating motor | 2sets |

|

3 |

Material | stainless steel 304 |

|

4 |

Screen | Two layer |

|

5 |

Quantity of air blower | 3set |

|

6 |

Motor power | 1.1kw/set |

8. Air blowing system

| Item | Description | remarks |

|

1 |

Air blower | 4kw |

|

2 |

Diameter of the pipe | 114mm |

|

3 |

Material of the pipe | stainless steel 304 |

|

4 |

The air tube with double layer ,it is water jacket design for this tube | |

9.Silo

| Item | Description | remarks |

|

1 |

Volume | 1.5m³ |

|

2 |

Diameter of the pipe | 114mm |

|

3 |

Material of storage hopper | stainless steel 304 |

|

4 |

The silo body in two layer, with water jacket cooling between two layer. | |