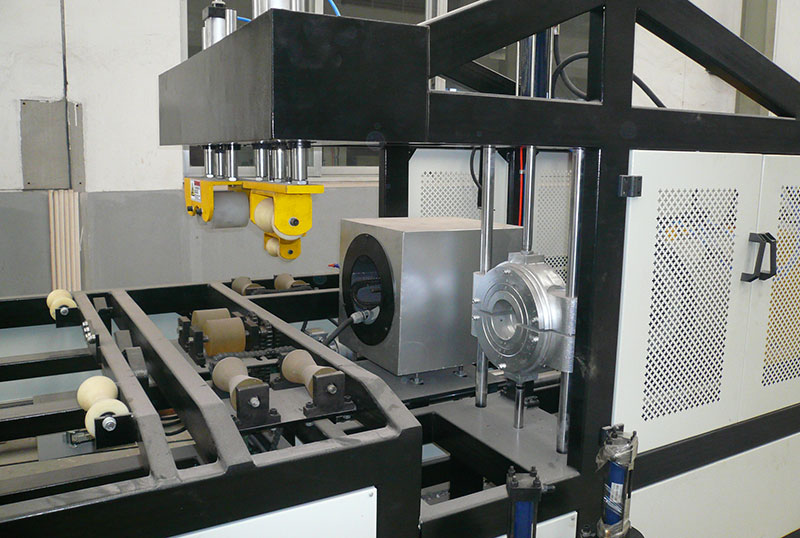

PVC Hot And Cold Plastic Mixing Machine/Mixer machine

Technical Parameter

| SRL-Z Mixer | Heat/Cool | Heat/Cool | Heat/Cool | Heat/Cool | Heat/Cool |

| Total Volume(L) | 100/200 | 200/500 | 300/600 | 500/1000 | 800/1600 |

| Effective Capacity (L) | 65/130 | 150/320 | 225/380 | 375/650 | 600/1050 |

| Mixing Time (min) | 8-12 | 8-12 | 8-12 | 8-12 | 8-12 |

| Output(kg/pot) | 50 | 90 | 120 | 180 | 300 |

| Autoloader

|

|||

| Item | Description | Unit | remarks |

| 1 | Transport tube diameter | mm | 102 |

| 2 | Charging motor power | KW | 1.5 |

| 3 | Charge capacity | Kg/h | 300 |

| 4 | Storage volume | kg | 150 |

| 5 | Material of storage hopper and tube | / | Stainless steel304 |

Usually PVC foam board machine we suggest SRL-500/1000 model mixer .

SRL-500/1000 hot and cooling mixer units

Technical parameters and related performance of equipment:

1. hot mixing part

Total volume of hot mix 510L

Effective volume of hot mix 380L

Feeding quantity per time 180-230kg/ pot

Productive capacity 720-920kg/h

Motor power 75kW (Kejie motor)

Slurry type Linear three-layer mixed slurry (stainless steel)

Bottom thickness 5mm

Thickness of inner wall of boiler 5mm

Hot mix speed 748 rpm

Mixing time 8-10 min / pot

Temperature during mixing operation ≤150℃

2. cold mixing

Volume of cold mixer 1000L

Effective volume of cold mixing 800L

Motor power 11KW

Reducer model WPO175 1:20

Cold mixed slurry One set of slurry stainless steel

Thickness of inner wall of boiler 5mm stainless steel

Thickness of outer wall of boiler 5mm iron pot

Bottom of pot 5mm stainless steel 8mm iron

Mixing speed 49 rpm

Cooling time 10-15 min / pot

Water supply in the interlayer of the cold mixing boiler Water pressure ≤ 0.3MPa

Water consumption 12 tons / hour (can enter the pool for recycling)

Most suitable discharging temperature ≤45℃

Suitable for water temperature 10-18℃

3. electrical part

Universal frequency converter 75kW, Tianzheng Zhengtai Electric Appliance, with heat dissipation and exhaust holes in the electric box

4. unloading method And lid

All pneumatic discharging and pneumatic cover lifting.

5.the feeding machine adopts screw feeding machine