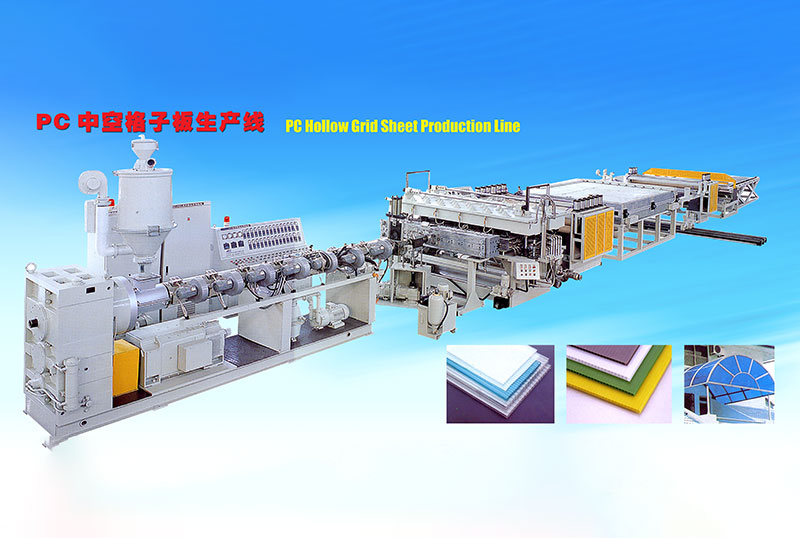

PVC foam board Production line

Specifications

| WPC or PVC Celuka foam board machinery details | |

| Main material | PVC/CaCo3/additives |

| Finished board size | 1220-2050mm(width)*2440mm(length-adjustable) |

| Finished board thickness range | 3-25mm/3-30mm |

| Max extruder capacity | 400kgs/h/600kgs/h/800kgs/h/1000kgs/h |

| Board surface treatment Co-extrusion |

Embossing/transfer print/lamination/UV coating/CNC engrave SJSZ80+SJSZ65 |

machines and advantages

1.Frequency inverter: ABB/DELTA

2.Full set Siemens electric parts: Main motor/AC contactor/thermal overload relay/circuit breaker(including the large circuit breaker of the whole line)/comment switch ,Contactor: Siemens contactor ,according customers need use Servo Governor, TAIWAN blowers

3.PLC:SIEMENS touch screen

4.Temperature controller: OMRON Japan

5.Relay/travel switch: Schneider France

6.Twin-Screw: famous brand from Zhoushan, China

7.Mould:China famous brand like: JC Times/EkO

Production line & Auxiliary machine

| NO. | Name of machine | Advantage of machine |

| 1 | Automatic screw feed loader | Fully automatic |

| 2 | Conical Twin Screw extruder SJSZ80/156 SJSZ80/173 SJSZ92/188 |

Inverted SIEMENS motor, famous brand gearbox and full set of SIEMENS electric control system,30% ENERGY SAVING, STABLE RUNNING, LONG SERVICE LIFE |

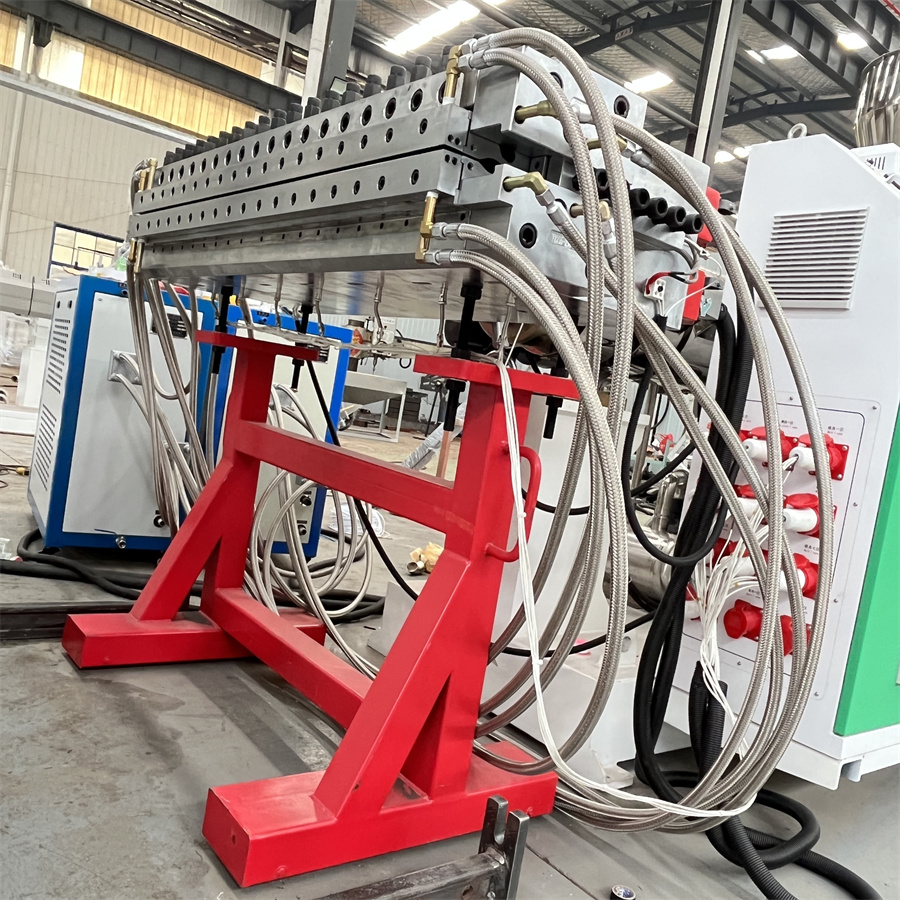

| 3 | T-die | Design by our self with over 10 years manufacturing experience Can use JC times |

| 4 | Calibrator unit | 100mm thickness mirror surface calibrator |

| 5 | Cooling Bracket | 9 pcs stainless iron rollers |

| 6 | Haul off machine | 8pairs/10pairs/12pairs rubber surface rollers |

| 7 | Transverse auto-cutter | Dust vacuuming collector |

| 8 | Stacker and manipulator | Full automatic |

| Auxiliary machines(optional) | ||

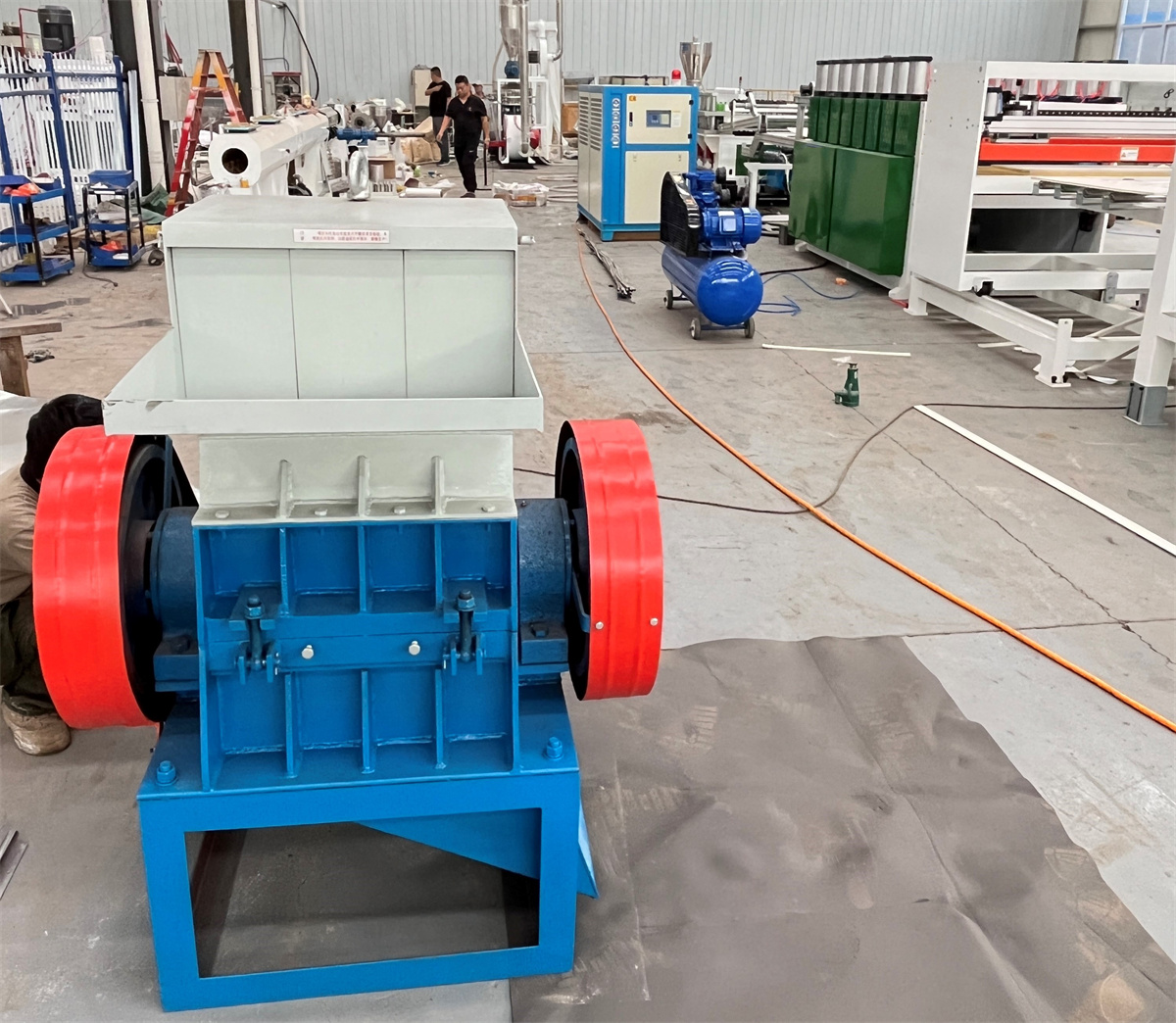

| 1 | Crusher | For recycling unqualified board, save material SWP380 |

| 2 | Grinder | For recycling unqualified board MF630 |

| 3 | High-speed Heat/Cooling Mixer | For mixing raw materials according formula 500/1000L or 800/2500L |

| 4 | Chiller | To supply cool water 20P |

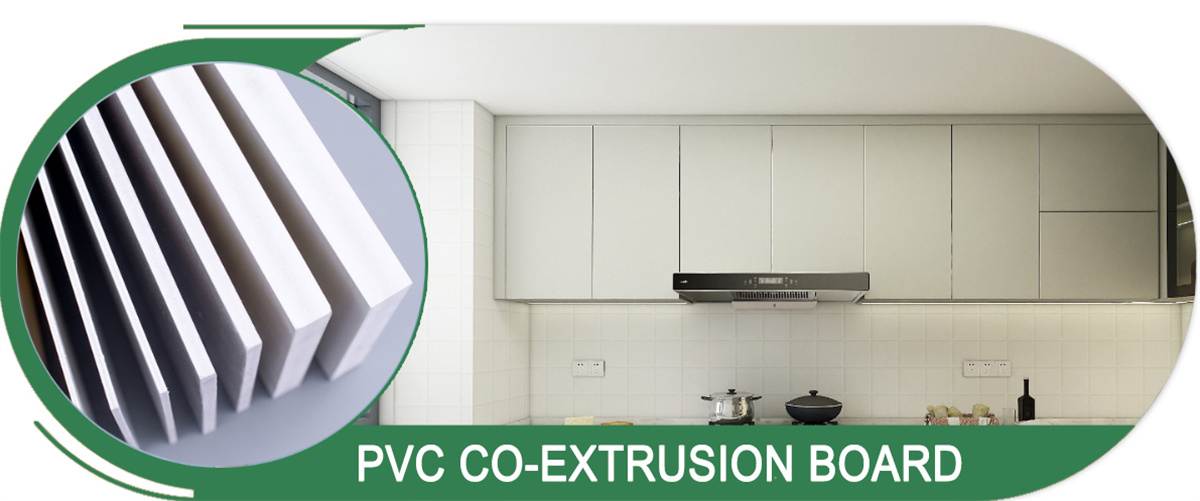

Application

Pvc furniture board is pvc crust foam board or Celuka foam board. Smooth, light weight , high density, high hardness , moisture-proof and waterproof , mildew proof and anti-corrosion , non-toxic and no benzene , green products , not easy to deformation resistance to compression. PVC furniture board (Chevron board or Andy board PVC high, hardness white crust foaming board ) household decoration: bathroom cabinet board, furniture board, household decoration board, all kinds of household of the shelf.

Our Service

Pre-sale service

To provide information and market research ,to provide consultation ,to provide many kinds of conveniences and market service ,etc.

The main purpose of pre-sales service is to help customers make the project planning and system requirements analysis. Make our products maximum to meet clients' requirements. Also play the greatest overall economic benefits of customers' investment.

After-sale service

To install products and test products freely for customers.

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

To direct technology aspect of relevant use according to customers' requirements

To provide technical training for clients' employees.

To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients' employees.