Pvc Electrical Cable Trunking Extrusion Line

Products Description

Pvc Electrical Cable Trunking Extrusion Line

Raw material:

PVC powder

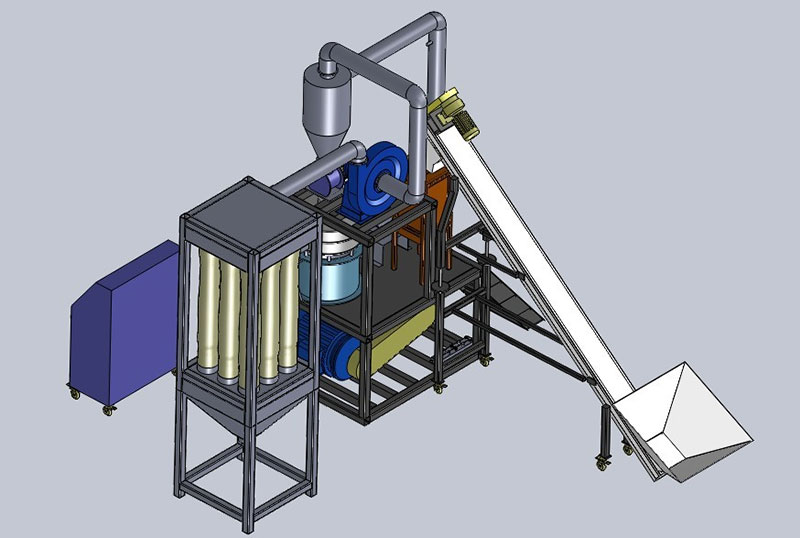

The whole production line includes:

plastic powder screw loader → SJZ 55/110 or SJSZ65/132 conical twin screw extruder →Profile Mold → Calibrator table→ Haul off machine → Cutting machine → 6 meters stacker

Use:For production of soft PVC profile, rigid PVC profile, soft-hard co-extrusion profile,foam profile extrusion, multi layer co-extrusion etc.

Technical parameter

specifications

* Whole line length about 18 meters

* Actual consumed power about 30 kw

* Extrusion capacity is 120-150 kg/h

* Extrusion speed is 2-3 m/min, it also depends on trunking size, engineer experience and extrusion mold quality

Main Features:

1. Extruder: Machine is equipped with a quantitative feeding device, which can match the extrusion amount and the amount of material, and ensure the stable extrusion of products.

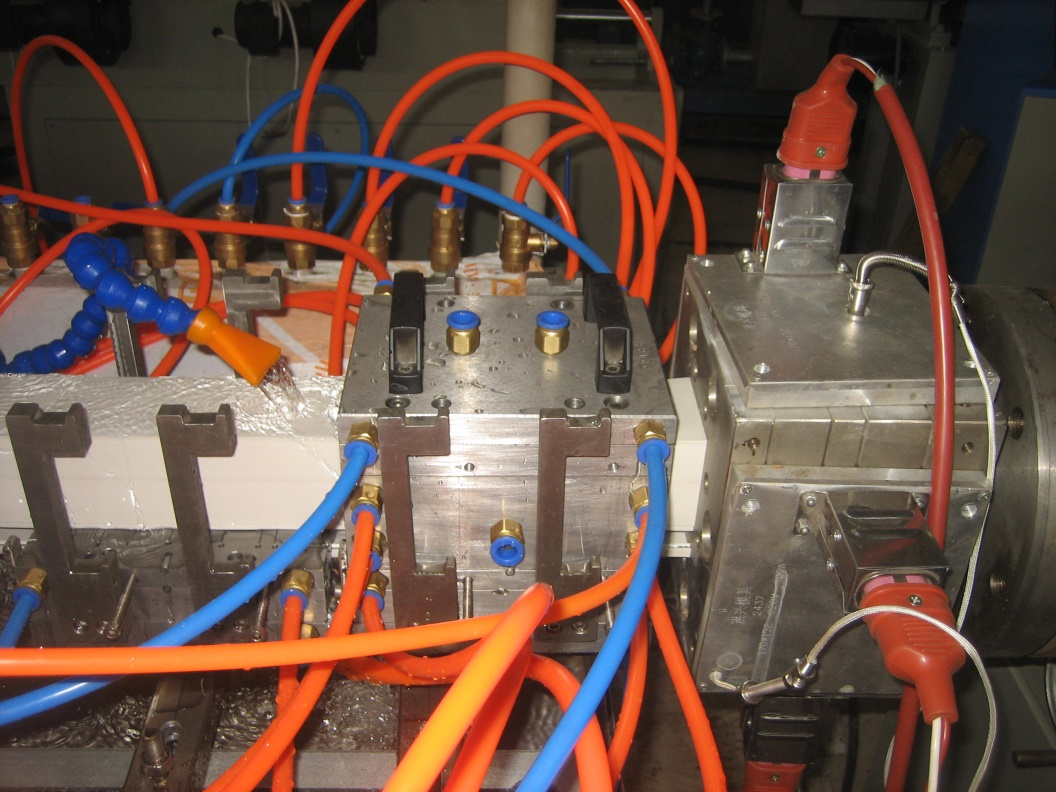

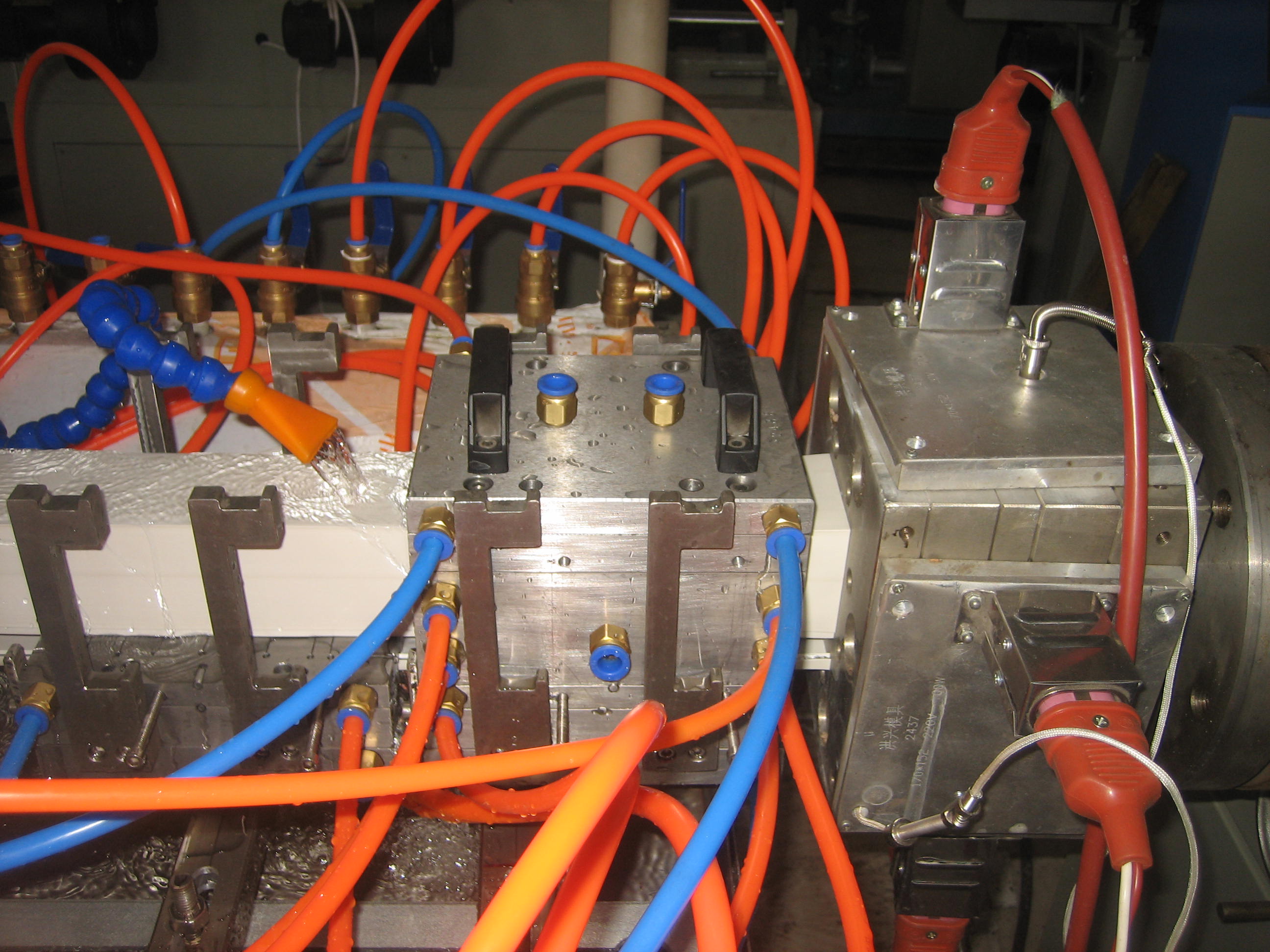

2. Mould Die: After compacted, melting, mixing, PVC material can be through the screw pushed into die, extrusion die head is the key part of profile forming.

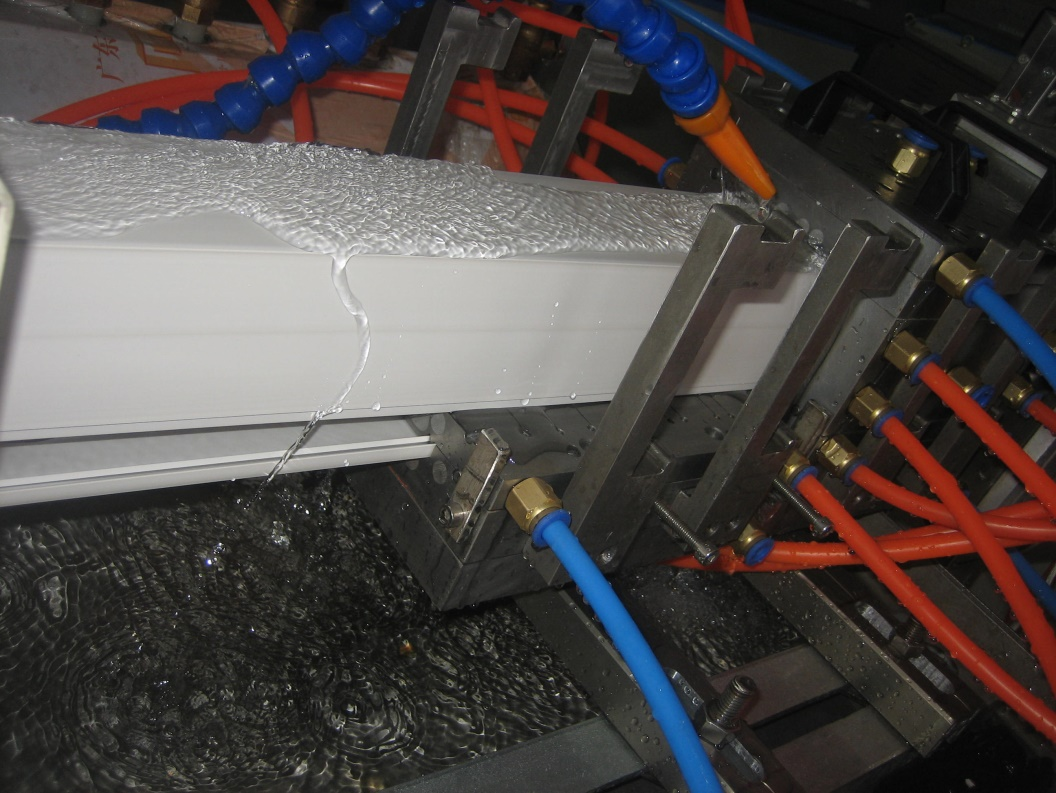

3. Vacuum Calibrating Cooling Tank is used for sizing and cooling, which is equipped with vacuum system and water circulation system, stainless steel casing, circulation water immersion cooling.

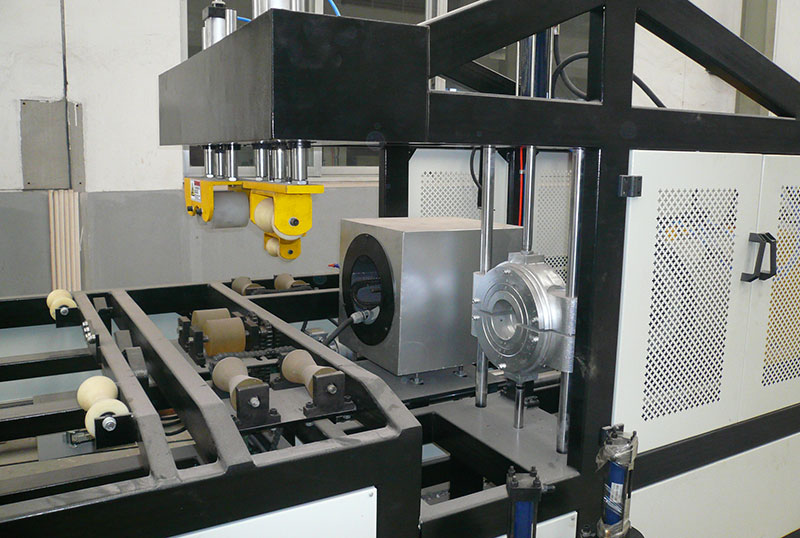

4. Traction Machine is used for the continuous automatic the cooled hardened profiles traction from the nose and frequency control.

5. Cutter: Trip switch will cut automatically according to the required length. The cutting process is driven by electric and pneumatic.

|

Max profile width (mm) |

Extruder model |

Designed capacity(kg/h) |

Extruder motor power(kw) |

|

180 |

51/105 or 55/110 |

80-120/120-150 |

18.5/22 |

|

240 |

65/132 |

175-250 |

37 |

|

300 |

65/132 |

175-250 |

37 |

|

400 |

65/132 or 80/156 |

175-250/250-350 |

37/55 |

|

600 |

65/132 or 80/156 |

175-250/250-350 |

37/55 |

|

800 |

80/156 |

280-350 |

55 |