PVC Door and Window Profile Extrusion Line

Project evaluation

According to your requirement, we’d like to recommend our SJZ65/132 PVC Profile Extrusion Line. This extrusion line is composed of SJZ65/132 Conical Twin-screw Extruder and downstream assistant machine. Please check the below information:

1.1 Material characteristics

1.1.1 based material:

- PVC powder:

- CaCo3:

1.1.2 Additive:

- Coupling

- Lubricant

- 1.1.3 Material form

- All the material should be mixed completely.

Finished product: PVC Profile;

Output capacity: 150~250kg/hr (depending on finished produce

The whole production line includes:

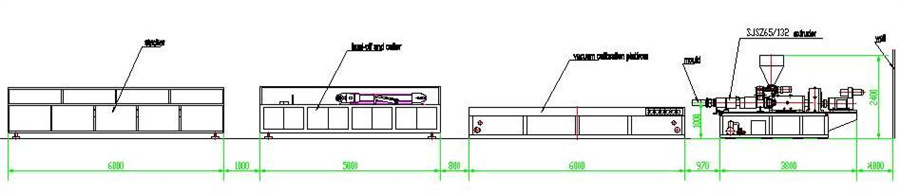

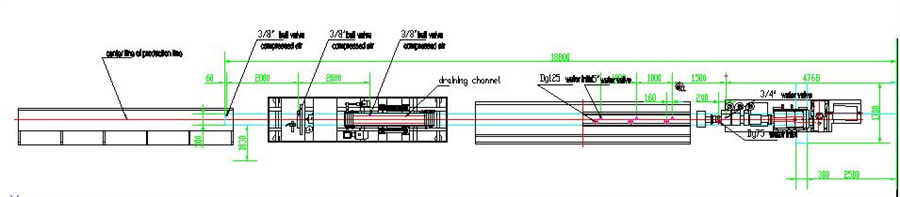

plastic powder screw loader → SJSZ65/132 conical twin screw extruder →Mold → Calibrator table→ Haul off machine → Cutting machine → 6meters stacker

Technical specification

SJZ65/132 PVC Profile extrusion line

|

No. |

Name |

Photo of machine | Qty. | Technical specifications | |

|

1 |

ZJ300 feeder |  |

1 |

Rated transmission capacity: 300kg/h | |

| Motor power: 1.5kw Spring diameter: Φ36mm Material: Stainless steel |

|||||

|

2 |

SJZ65/132 conical twin-screw extruder |  |

1 |

2.1 screw 2.2 barrel 2.3 driving motor 2.4 feeding system 2.5 Vacuum system 2.6 Adaptor 2.7 Main electric cabinet Self-protective system |

|

| 2.1 Screw: diameter conical 65/ 132 mm for PVC drainpipe and water supply pipe. Material of screw: 38CrMoAl Surface treatment: Nitriding processing, thickness: 0.6 ~ 0,8mm, Polishing Rotating speed (counter rotating): 1-34.7 rpm/min 2.2 Barrel: diameter conical 65/132 Inner processing: nitrided with thickness: 0.6 ~ 0.8mm Heating zones: 4 Heating mode: Cast alumina + stainless steel covering Heating power: 22kw Cooling mode: Air fans: 3 Sets 2.3 Driving motor: Motor power: 37Kw Type of motor = AC 2.4 Feeding system: Gravity and screw dosing feeding system With stainless steel hopper Dosing feeding system: Motor: 1.5Kw Feeding sleeve with circular water cooling 2.5 Vacuum dehumidifying system: Vacuum pump: 1 set Vacuum degree = 0 ~ 0.075 Mpa 2.6 Adaptor: (Interflow Section): Material: #40steel Chrome plated, inner convergent flow type Connection method with die: clamping block + bolt Pressure melt sensor and thermocouple 2.7 Main electric part supplier : Inverter: ABB or DELATA Contactor: Schneider or SIEMENS Air Switch: Schneider Relay: Omron Temperature controller: RKC 2.8 Self protective system: Over current protective of motor Over pressure protective of screw. |

|||||

|

3 |

YF240 Calibration platform |  |

1 | 3.1 Exterior dimension 3.2 Vacuum pump 3.3 Water pump 3.4 Three direction adjustment: Contact water part are made by stainless steel. |

|

| 3.1 Exterior dimension: Lx W x H: 6000x1100x1000mm (adjustable) 3.2 Vacuum pump: Vacuum pump: 3x5.5KW; Origin: Yuanli, China 3.3 Water pump: Water pump: 1×4KW; Origin: Guangzhou, China 3.4 Three direction adjustment: Forward and Backward with 0.75 Kw motor Range: ±1000mm Up and down, left and right manually adjusted Range: up and down: ±150mm LEFT and RIGHT moving: ±50mm |

|||||

|

4 |

DYⅢQ Haul-off and cutter (combined) |  |

1 | 4.1 Haul-off 4.2 Cutter |

|

| 4.1 Haul-off Haul-off speed: 0-3m/min; Motor power: 5.5KW; Caterpillar width: 210mm; Caterpillar length: 2200mm; Pneumatic clamp; Adopt holip or ABB inverter; 4.2 Cutter Motor power: 2.2KW; Scrap collecting motor power: 1.5KW; Diameter of saw: 500mm; Cutting range: 200mm; With scrap collecting device; |

|||||

|

5 |

Tipping table |  |

1 | 5.1 Tipping table: Length Control method Height adjusting range |

|

| Length: 6,000mm Control method: Pneumatic With screws to adjust the height range: 0 ~ 180mm |

|||||

6.Mixing equipments

1. Application:

Mix raw material

2. Output: ≤500

3. Equipment components:

① hot mixer

② cooling mixer

③ autoloader

4. Parameter

| Model | / | SRL-Z300/600 mixer group | ||

|

||||

| 1 | Hot mixer | |||

| 2 | total volume of hot mixer | L | 300 | |

| 3 | effective volume of hot mixer | L | 225 | |

| 4 | material weight/batch | ㎏/batch | ≤100 | |

| 5 | Output | ㎏/h | ≤500 | |

| 6 | motor power | KW | 40/55, double speed motor | |

| 7 | heating power | KW | 12 | |

| 8 | hot mixer rotating speed | r/min | 475/950 | |

| 9 | Quantity of stirring blade | pcs | 3(1Cr18Ni9Ti) | |

| 10 | mixing time | min/batch | 8-10 | |

| cooling mixer | ||||

| 1 | cooling mixer volume | L | 600 | |

| 2 | effective volume of cooling mixer | L | 450 | |

| 3 | motor power | KW | 11 | |

| 4 | material of cooling mixer blade | / | ZG1Cr18Ni9Ti | |

| 5 | stirring blade rotating speed | r/m | 130 | |

| 6 | lift control method | / | pneumatic | |

| 7 | Cooling method | / | water cooling | |

| 8 | cooling time | min/batch | 10-12 | |

| Electrics | ||||

| 1 | AC contactor | / | Schneider | |

| 2 | Temperature controller | / | Omron | |

| Autoloader | ||||

| 1 | Transport tube diameter | mm | 101 | |

| 2 | Charging motor power | KW | 1.5 | |

| 3 | Push material motor power | KW | 0.55 | |

| 4 | Storage volume | kg | 80 | |

| 5 | Material of storage hopper and tube | / | Stainless steel | |

7 Plastic crusher (optional)

Application: crush waste PVC sections for recycling use

| model | SWP- 400 |

|

|

| Diameter of Rotating blades | 400mm |

| Rotating blade quantity | 5 |

| Rotating speed | 500r/min |

| Fixed blade quantity | 2 |

| Aperture of screen (mm) | 10 |

| Crushing capacity | 350-450 kg/h |

| Power(kw) | 13.2 |

| Feeding mouth(mm) | 375*320 |

| Weight(kg) | 980 |

| Size(mm) | 2500*1200*2000 |

8. PVC pulverizer (optional)

Application: grind crushed PVC pieces into powder

|

|

| Diameter of crushing room(mm) | 400 |

| Number of rotor | 3 |

| Main shaft speed(r/min) | 3400-3700 |

| Motor power (kw) | 30 |

| Output capacity (kg/h) | 50-150 |

| Weight (kg) | 1000 |

Flow line and configuration for PVC profile production line

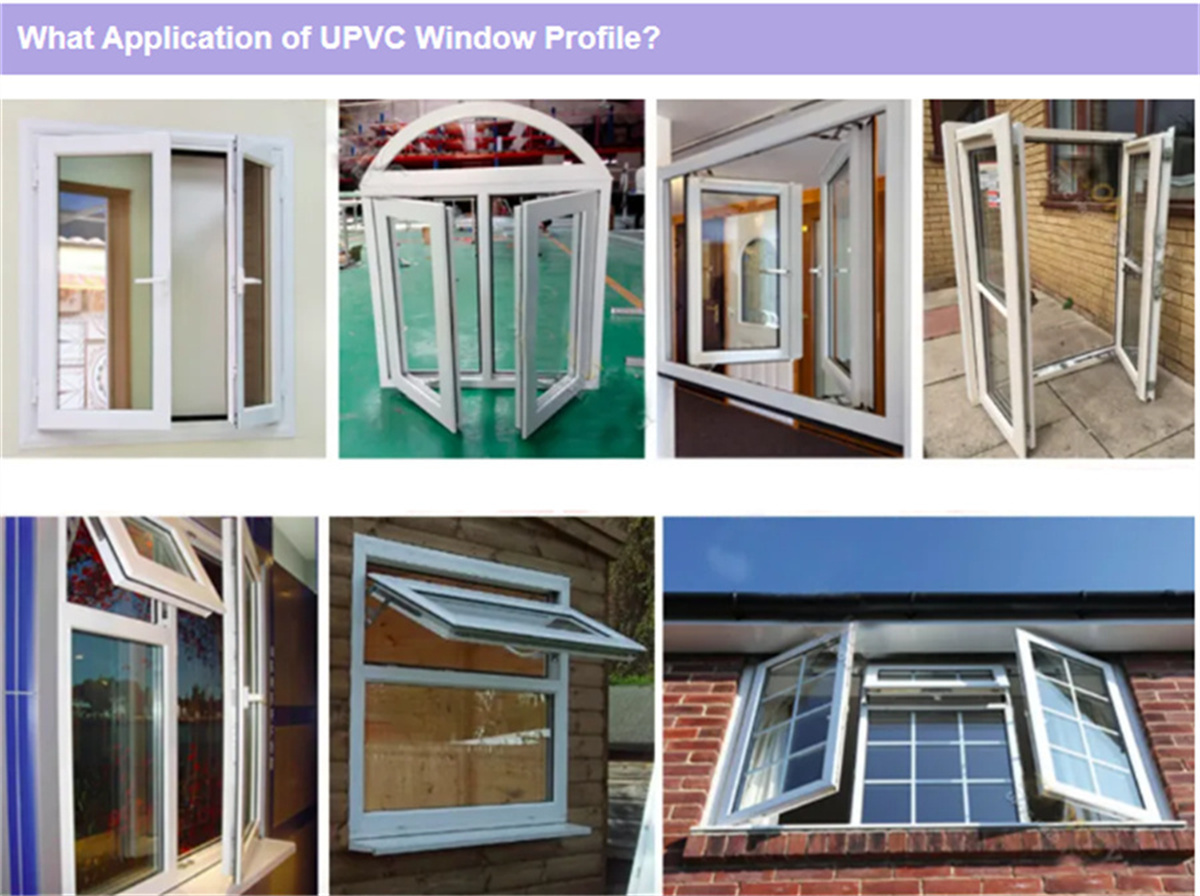

Application

Divided according to opening mode:

Fixed window, upper suspension window, middle suspension window, lower hanging window, vertical window, flat open window, pulley flat window, pulley window, flat open down door and window, sliding door and window, push flat window, folding door, ground spring door, lifting sliding door, push pull folding door, internal back sliding door.

PVC Profile has such characteristics as sound separation, sound absorption, heat separation, temperature-keeping ,etc. The material is incombustible, it is safe for use.

All series of products have property of moisture proof, mildew proof, water resistance, its vibration resistant effect if good. All series of products have property of weathering proof, its luster may remain forever, it is not easy to be ageing. This product is light, storage & transport, construction are rather convenient. This product can be worked with normal tools for wooden material. Drilling, sawing, nail, planing, bonding can be conducted like wooden material. It is suitable for thermal shaping, thermal bending and fold processing. It can be welded, it can also be bonded with other PVC material. The surface of this product is smooth, it can be printed.(Clean the surface before printing.)