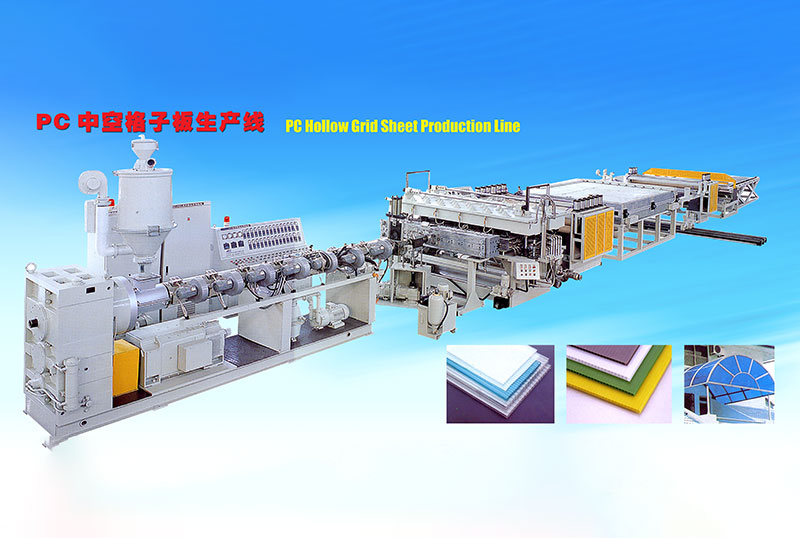

Pvc Decoration foam Board Extrusion Line

Pvc Decoration foam Board Extrusion Line /Foam Board Extruder Machine is Used to make construction panel, decoration panel,balustrade, pavement, steps, outdoor tables, wall panel and chairs, pergola, tree bed, etc. Material: 30-60% straw, wood flour, rice chaff mixed with recycled PVC, PP, PE powder. Undecomposable, deformation free, fade resistant, insect damage resistant, good fireproof performance, crack resistant, and maintenance free etc.

PVC Crust Foam Board Plastic Extruder machine PVC Board Making machinery pvc celuka foam board equipment

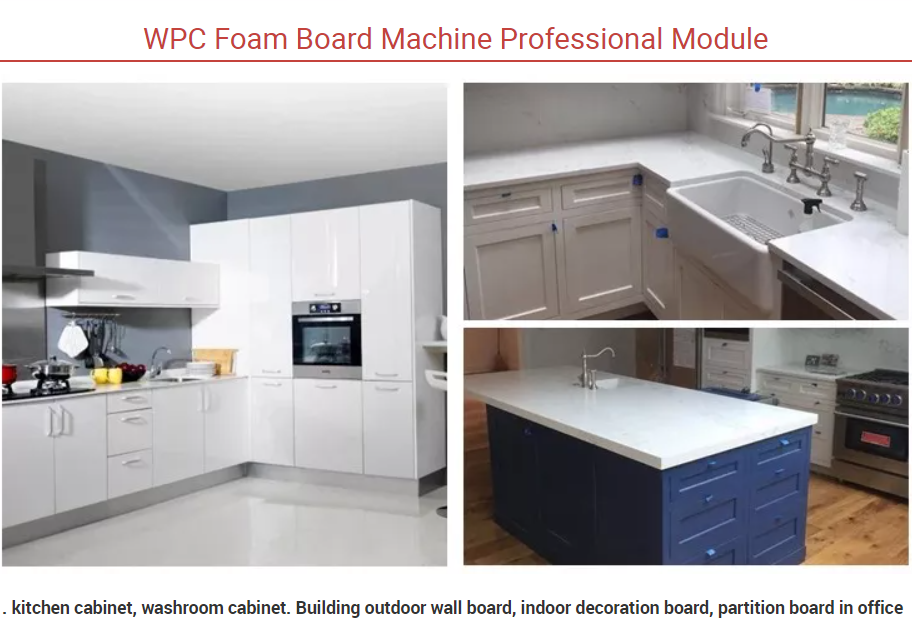

Kitchen Furniture foam board production machine pvc foam board manufacturing plant supplier

PVC WPC Sheet is a new material for both inside or outside decoration. It has hard and smooth surface, which can be laminated by various materials such as PVC film, impregnated paper, etc. It opens a new world of decoration, the laminated board is not only waterproof, UV resistant and anti-corrosion, but also special and beautiful. WPC sheet is like wood, but it is much better than wood.

Work flow

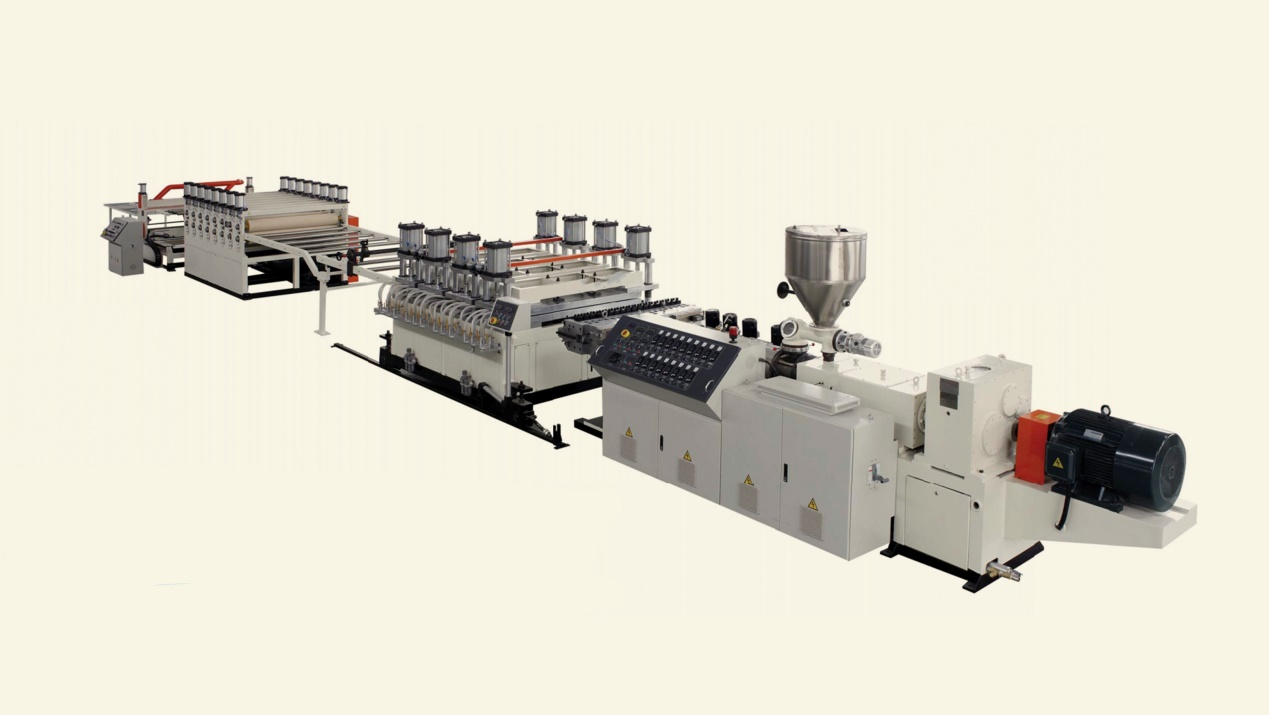

PVC powder +additive → mixer →SJSZ series extruder →Coat-hanger type mould →Vacuum calibration cooling platform →cooling rollers and edge-cutting device →Haul off →stacker

Product Description

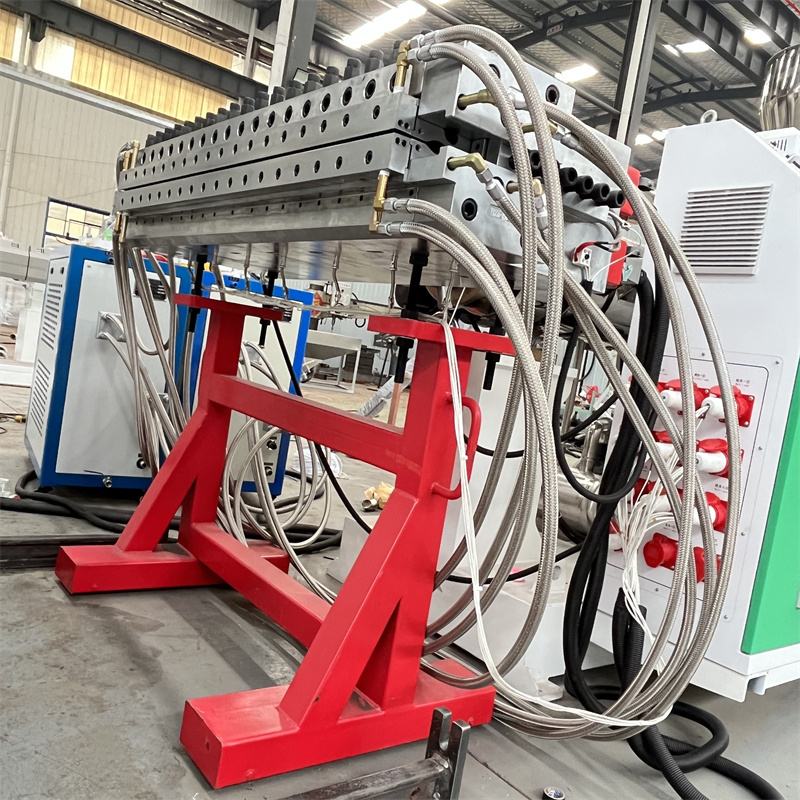

Main feature of Plastic PVC WPC wood plastic composite foam board extrusion line/door board Making Machine/extruder:

1. Frequency converter: ABB/DELTA

2.Full set Siemens electric parts: Main motor/AC contactor/thermal overload relay/circuit breaker(including the large circuit breaker of the whole line)/comment switch;

3.PLC:SIEMENS

4.Temperature controller:OMRON Japan

5.Relay/travel switch:Schneider France

6.Twin-Screw: famous brand from Zhoushan,China

7.Mould:China famous brand like:JC Times/EkO/Weilei

| WPC PVC Celuka foam board basic information: | |

| Main material | PVC/CaCo3/addtives |

| Finished board size | 1220-2050mm(width)*2440mm(length-adjustbable) |

| Finished board thickness range | 3-25mm/3-30mm/3-40mm |

| Max extruder capacity | 400kgs/h/600kgs/h/800kgs/h |

| Board surface treatment | Embossing/transfer print/lamination/uv coating/CNC engrave |

MACHINE LIST

| No. | Name | Qty. | Remark |

| 1 | Screw loader for extruder | 1 | |

| 2 | SJZ 80/156 conical twin screw extruder | 1 | |

| 3 | Extrusion mould unit | 1 | 1220*2440 |

| 4 | Vacuum calibration Table | 1 | |

| 5 | Cooling bracket | 1 | |

| 6 | Haul off unit | 1 | |

| 7 | Edge cutting device | 1 | |

| 8 | Tracking cutter | 1 | |

| 9 | Automatic shift machine | 1 | |

| 10 | Dust collection device | 1 | |

| 11 | Mould temperature controller | 1 |

| Auxiliary Machine | |||

| 12 | SRL-Z Series Mixer unit | 1 | Capacity : 450-550kg/h |

| 13 | Screw loader for Mixer | 1 | |

| 14 | Crusher | 1 | Power: 11kw,22kw,30kw |

|

15 |

Pulverizer | 1 | Power: 45kw,55kw,75kw |

MACHINE SHIPMENT

We ship 2*40HC containers to our aboard customer