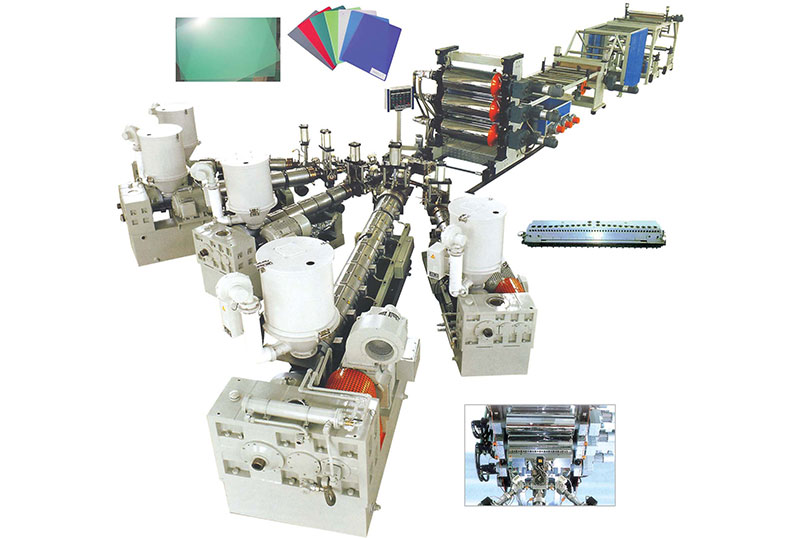

Pvc Crust Foam Board Extrusion Machine

production line list

| No | Name | Type | Quantity | Marks |

| 1.1 | Conical twin screw extruder

With automatic spring feeder |

SJSZ-80/156 | 1set | Equipped with automatic spring feeder |

| 1.2 | Electrical control system | 1set | Delta frequency converter, Siemens contactor | |

| 1.3 | Mould | SJM-1350 | 1set | Oil string device at die port, automatic temperature control |

| 1.4 | Vacuum setting die | SDX-1500 | 1set | 4-stage sizing cooling |

| 1.5 | Hauling off | SQY-1400 | 1set | 8 sets, 16 rolls. |

| 1.6 | Cooling bracket | SJTJ-3000 | 1set | |

| 1.7 | Longitudinal cutting device | SQG-1220 | 1set | |

| 1.8 | Transverse cutting machine | SQG-1220 | 1set | |

| 1.9 | Plate unloading device | SJS-1220 | 1set | |

| 1.10 | Hot and cold mixer | SHR500/1000 | 1set | |

| 1.11 | Crusher | SWP-380 | 1set | |

| 1.12 | Grinder | SMP-630 | 1set | |

2. Pvc Crust Foam Board Extrusion Machine instruction

| NO | INSTRUCTION | SPECIFICATION |

| 2.1 | RAW MATERIAL | PVC Add auxiliary materials |

| 2.2 | BOARD SIZE | 5-25×1220 |

| 2.3 | Line speed | 0.7-1m/min |

| 2.4 | MAX OUTPUT | 350-500kg/h |

| 2.5 | MACHINE SIZE | 26000×2200×2900 L×W×H |

| 2.6 | WEIGHT | 35t |

| 2.7 | Total installed power | 175kw |

| 2.8 | Actual energy consumption power | 11kw |

| 2.9 | Gas consumption | 0.4m3/min |

| 2.10 | pressure | 0.8mpa |

| 2.11 | Water circulation | 0.4 m3/min |

| 2.12 | VOLTAGE | AC380V±10%50HZ |

| 2.13 | WATER | Industrial water, free of impurities, filtered, water pressure: 0.4MPa, water temperature: 15-25 ℃. |

| 2.14 | work environment | 0-40℃ |

| 3.technological process |

| Raw material allocation→LOADER MATERIAL → EXTRUDER→T DIE MOULD→CALIBRATION TABLE→COOLING FRAME →8 ROLLERS HAULING OFF→ Longitudinal cutting device→Transverse cutting →transportation→test →package |

4. Pvc Crust Foam Board Extrusion Machine Application:

widely used in the construction industry and advertising decoration industry: spray painting, display boards, screen printing, computer lettering, signs, light boxes, etc. Decoration industry: Indoor and outdoor decoration boards, commercial decoration shelves, room partition, ceiling boards, cabinets, bath cabinet ceiling boards and so on. Transportation industry: ships, aircraft, buses, train cars, ceiling, car body core layer, interior decoration board and other fields.

We are professional in the production of foam board equipment, continuous improvement of the pursuit of perfection. Using international famous brands as the main parts of the machine, from the attention to machine quality, reasonable design of machine structure to save electricity, improve production, convenient customer operation and other details. We will continue to strive to provide better service to our customers, we formed a set of technology ,research and development ,production ,sales ,such us multi-functional in one of the excellence team .PVC foam board belongs to a new satisfied green sheet which can replaces wood sheets .JIASHANG plastic machinery is the best professional manufacturer of PVC WPC foam board production line .

5.our Pvc Crust Foam Board Extrusion Machine shipment photo :