PS PMMA Acrylic Rod extrusion line

Products Description

PMMA Acrylic Advantage

1.Smoothly surface

2.High transportation and varies shape design

3.Easy operation

4.Low hydroscopicity

5.High transparency just like crystal pipe

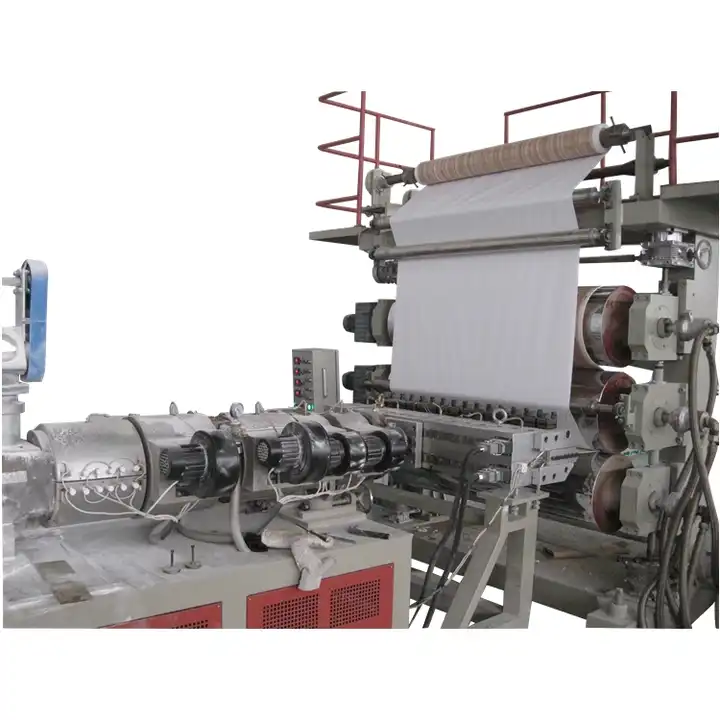

PMMA ACRYLIC Pipe/ Bar /Rod/ Stick Extrusion Line

The process flow of PMMA ACRYLIC pipe bar production is as following:

Loader → Dryer → Single-screw Extruder→ Mould→ Vacuum Calibration→Oil Cooling Tank →Water cooling tank →Hauling-off → Cutter →Pipe stacker

SYSTEM CONFIGURATION OF THE PRODUCTION LINE:

1. 1 set of Automatic loader

2. 1 set of Hopper dryer

3. 1 set of Single-Screw Extruder / small extruder for bubble

4. 1set of Mould with calibration

5. 1 set of Oil Cooling Tank and 1 set Water Cooling tank

6. 1 set of Hauling off Machine

7. 1 set of Pipe Cutting Machine

8. 1 set of Pipe Stacker

Feature

| Product Name | Colored Acrylic Plastic Solid Round Rods/Sticks |

| Diameter (mm) | can be customized |

| Length (m) | 2m or any length as requested |

| Color | transparent, can be customized (red / blue / yellow...) |

| Form | round, can be customized (square / triangular / oval ...) |

| Material | acrylic, PMMA |

| productive technology | extrusion & cast |

| Usage/Application | various for building, lighting, toy, furniture, ect,..... |