-

WPC PVC Crust Foam Board Extrusion Line

Screw、barrel design and manufacturing absorb European advanced technology

Screw and barrel material:38CrMoAlA,Nitriding treated

WPC PVC Crust Foam Board Extrusion Line,Plastic PVC Crust Foam Board Artificial Marble Stone Sheet Extrusion Production Machine,PVC Crust Foam Board/Plate Production/Extrusion Line Plastic Sheet Making Machine,PVC Wood-Plastic Crust Foam Board Extrusion Machine for Decoration。

-

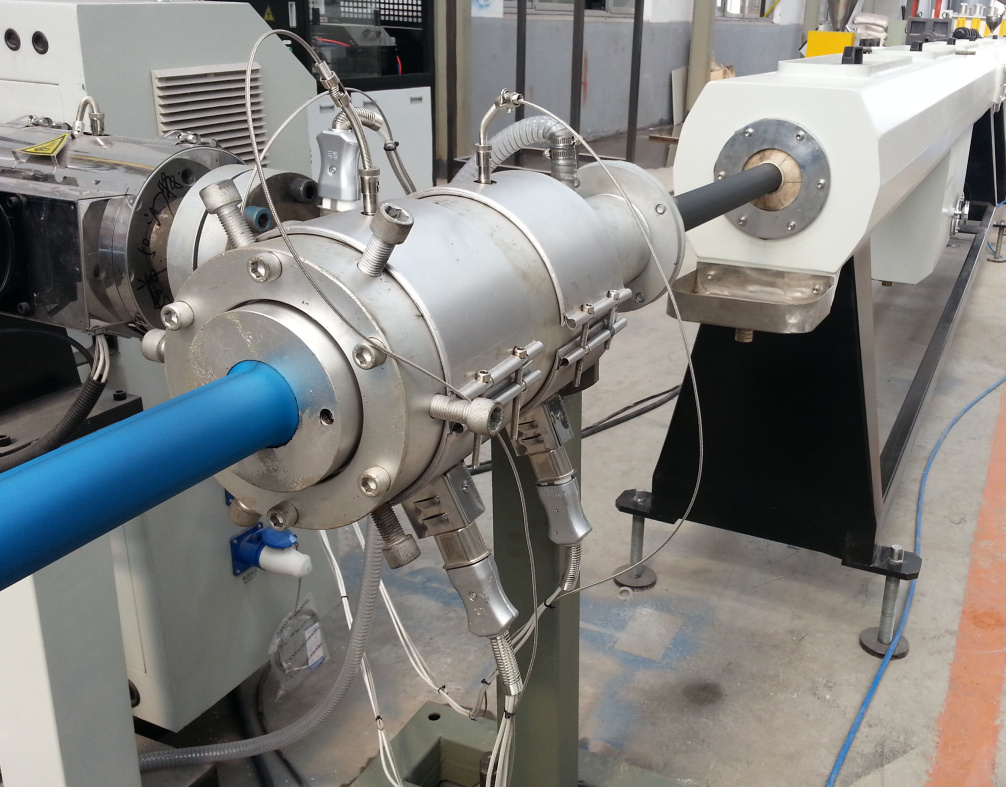

PVC multi-layer co-extrusion pipe production line

PVC multi-layer co-extrusion pipe line( three layers pipe line )

use SJSZ series double screw extruder

-

PVC milling pulverizer

PVC milling pulverizer, High Efficient PVC PP PE Plastic Waste Milling Machine Plastic Pulverizer for Pipe Profile Scrap

● Save and simple adjustment of cutting gap

● Low drive power and High throughput

● Innovative efficient design

● Easy to maintain and control

● Wide range of accessories

● Automatically regrinding coarse powder

● Dual cooling system

-

Muliti-layer CPVC UPVC pipe extrusion line

Plastic Pipe Extrusion mold is a kind of molding mold, but his way of discharging is to achieve through the action of extrusion.It is widely used in aluminum shaped structure and also in plastic parts.In the front end of the extruder, used for making pipe, or profile. In short, the mold is used to shape the tool, this tool is composed of various parts, different mold is composed of different parts, it mainly through the formation of material physical state change to achieve the shape of the object processing.

-

Pvc Decoration foam Board Extrusion Line

Pvc Decoration foam Board Extrusion Line /Foam Board Extruder Machine is Used to make construction panel, decoration panel,balustrade, pavement, steps, outdoor tables, wall panel and chairs, pergola, tree bed, etc.PVC Co-Extrusion Foam Board Production Line Twin-Screw,China Plastic PVC Crust/Free Foam Board Imitation Artificial Marble Stone Sheet Spc Vinyl Stone Plastic Floor Flooring Extrusion Production Making Line

-

PVC Pelletizing Line (Capacity: 350-400kg/h)

PVC Pelletizing Line (Capacity: 350-400kg/h)

Part 1. Process flow of PVC pelletizing line

Feeder→Mixer →feeder→extruder→hot-face pelletizer→air blowing system→Silo→vibrator sieve→air blowing system→Silo

-

High speed PE small pipe production line

High Speed PPR PP PE Plastic Plastic Pipe Extrusion Extruder Machine Production Line

Single Screw Plastic Extruder PPR/Pert/PE Pipe Production Line/High Speed Hot and Cold Water System /Saving Energy/Stable Production Machine

1.The pipes are extruded by the first extruder and then enter the twist form machine, at the same time the basket co-extrusion mould forms pipes’ shape.

2.The pipes are based on high density PE as main raw material.

-

PE PVC Double Wall Corrugated Pipe Extrusion Machine

PE PVC Double Wall Corrugated Pipe Extrusion Machine

1.High cost performance and long life

2.High stability and precision performance

3.High automation degree

4.High production efficiency

5.Good after-sales service -

PVC Electric Conduit double Pipe Extrusion Machine

16mm-40mm Plastic PVC Conduit Pipe Extrusion Line,The capacity of the profile can be selected from 50-800kgs / hour. Hauling off machine application of our company’s unique lifting technology. It has the advantages of stable operation, good reliability and large pulling force. The vacuum setting adopts a special enlarged eddy current cooling system, which is conducive to cooling and calibration to meet the needs of high-speed extrusion. The movement speed of the cutting machine is synchronized with the wire drawing speed. All actions are controlled by imported PLC, reasonable design, stable operation, automatic cutting length.

-

110-315mm PE pipe production line

HDPE PE PP PPR PVC Pipe Making Machine Plastic Water Supply Energy Pipe Tube Production Line Extrusion Extruder Machine

Agricultural Irrigation water supply&Discharge system&Gas supplly system& rchitectural water supply.

Production Flow

of Pipe Production Line: Hopper Dryer →Single Screw Extruder →Extrusion Mould → Co-extruder→Vacuum Calibration Cooling Tank →Spray

Cooling Tank → Haul-off Unit →Cutter →Stacker -

PP,PE coating pipe production line

PPR PP HDPE PE Plastic Pipe Extrusion Machine/Making Machine/Production Line

Newest technology with Spiral design.

Good quality 40Cr steel with Nitrogen quenched to reinforce the quality.

Newest design of Die support trolley, with easy adjustable factures -

PP-R three layers pipe production line

Plastic HDPE PPR Pipes Multi-Layer PE Tube Co-Extrusion Production Line

Plastic Multi-Layer Pipe PPR Pipe Extrusion Production Line Machine

1. Pipe extrusion line for production of three-layer pipes reinforced with fiberglass.

“Fiber PPR” PPR-GF (Glass Fiber) is a mixture of polypropylene randomly copolymer and glass-filled polypropylene.

Field of application: Pipes for pressure water supply. (For hot or cold water supply, for heating)

Pipe diameters: 16-63mm and 75-110mm