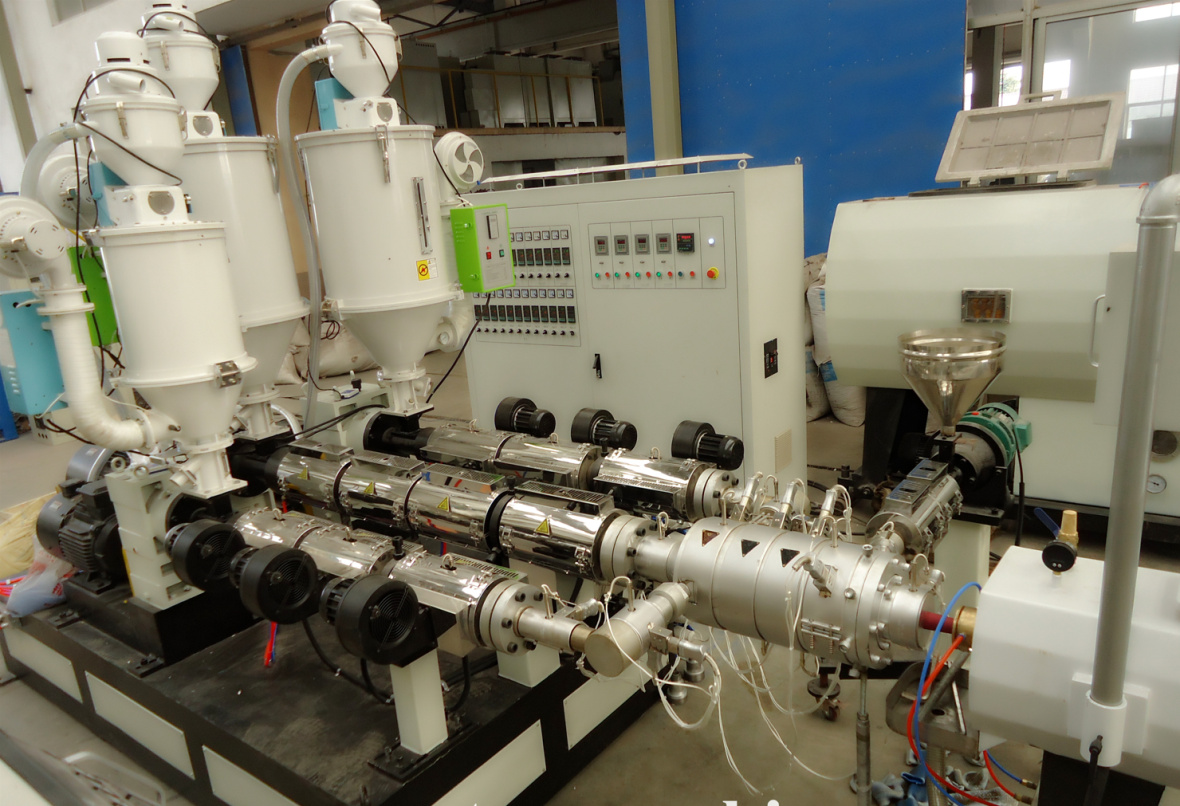

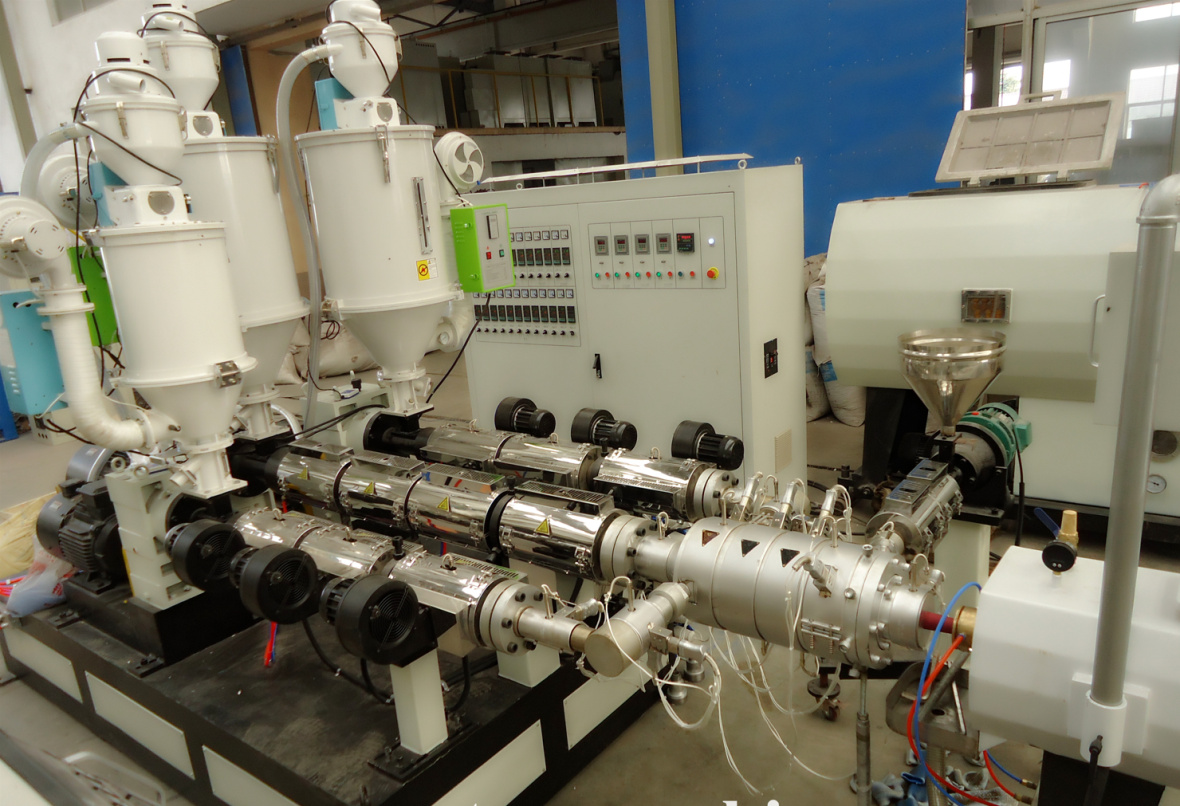

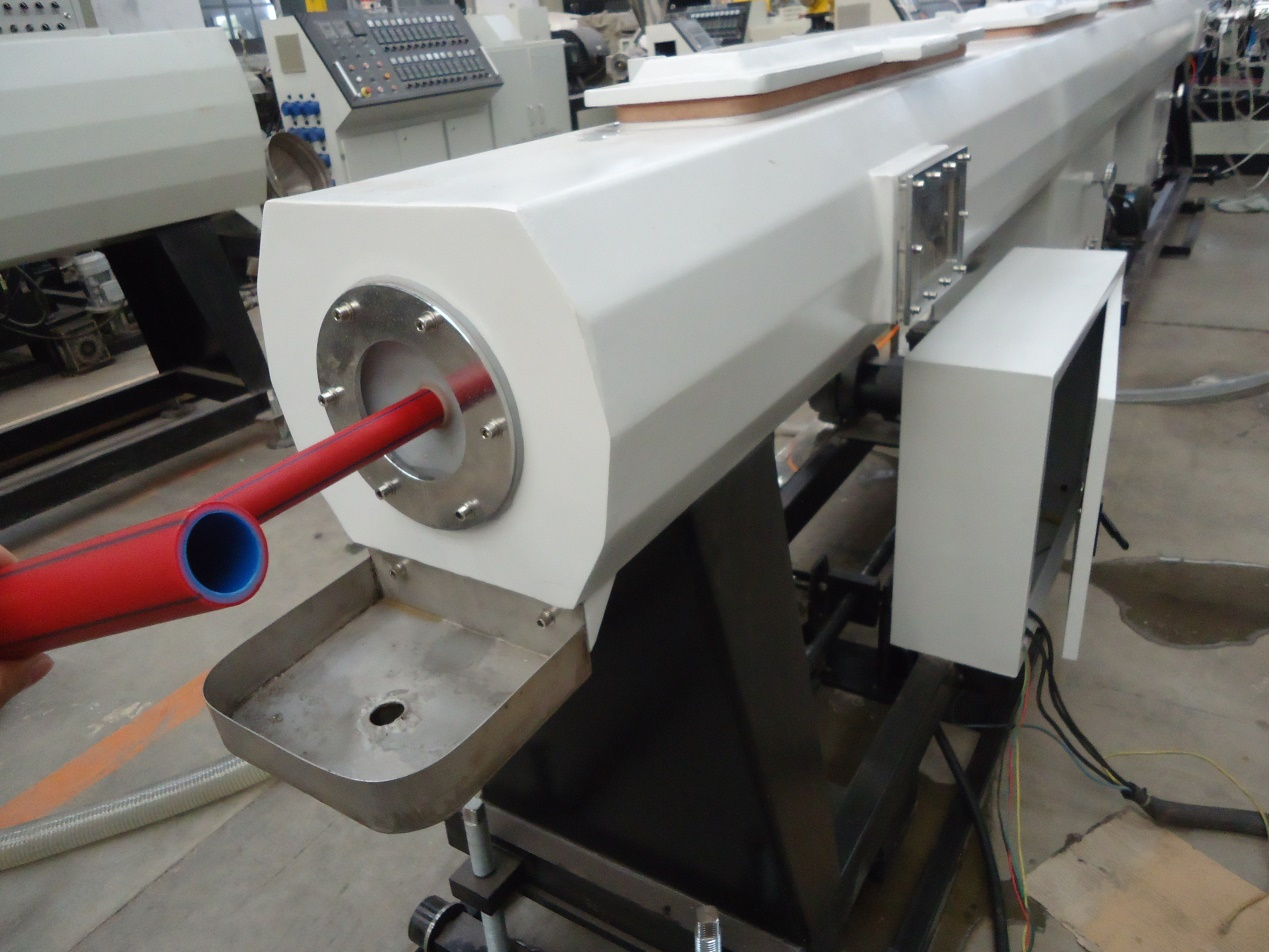

PP-R three layers pipe production line

Product Details

2. Process Flow of PPR Pipe machine line:

Raw material +master batches → mixing→vacuum feeding → material dryness → two or three single screw extruders → color color co-extruder → co-extrusion pipe mould → calibrator tank → spray vacuum calibration tank → spray cooling

water tank → Inkjet printer →haul-off machine → no-dust cutting machine → pipe stacker/winder → finished product inspecting &packing

3. ppr pipe extrusion line

1. Recyclable material: Polypropylene, fiberglass. 2. Diameters of the produced pipe: 16,20, 25, 32. 40. 50. 63, 75, 90, 110 mm. 3. The ratio of the layers (PP/PPR / glass fiber / PP/PPR): 40% -20% -40% 4. Productivity: 1.6-15m / min 5. The maximum productivity: 200-250kg\h 6. Installed power: 150kw 7. Line dimensions: 35,000 * 1400 * 2750(mm) Sale, commissioning, warranty and post-warranty service.

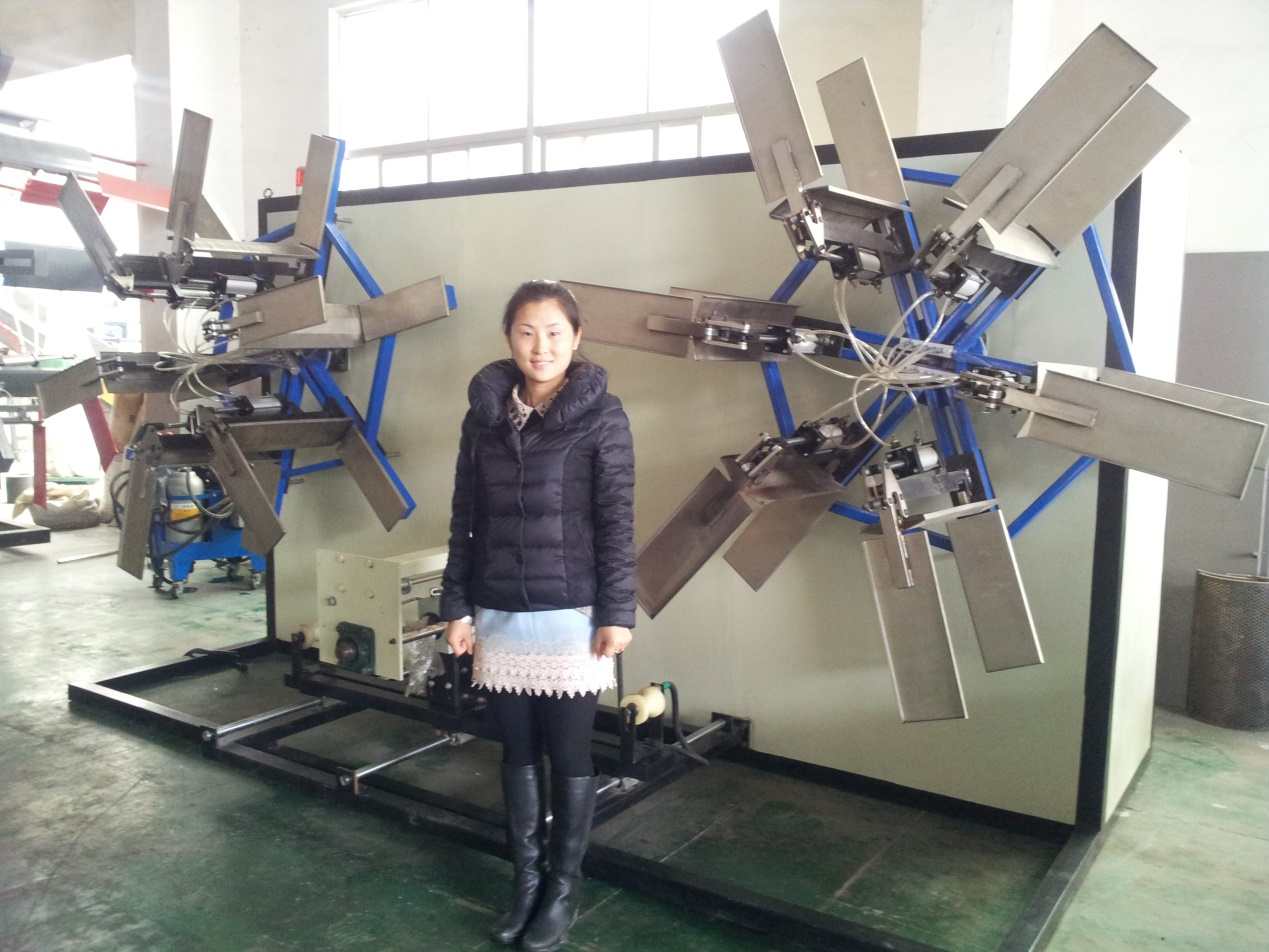

1.The machine is used to produce PVC steel wire reinforced transparent pipes.

2.The pipe wall is made of transparent PVC plastic in the pipe inner-wall, there are spiral steel wire.

3.The kind of pipe has the advantage of extrusion resistance, corrosion resistance, static electricity high pressure or combustible gas and liquid, heavy suction and delivery of liquid elude.

4.It is mainly used in machinery, such as chemical industry, building, irrigation and vacuum pumps, etc.

1. Plastic Automatic Charger/Пластмассовый Автоматический Обвинитель

| Charging capacityСпособность | 200kg/h |

| Charging Vortex PumpНасос Вихря | 1.1KW |

2. Hopper Plastic Dryer/Сушилка Пластмассы Бункера

| Hopper volumeОбъем бункера | 160L |

| Capacity (kg)Способность (кг) | 100kg |

| Heater powerНагревающяя мощность | 5KW |

| Fan motorДвигатель вентилятора | 0.25KW |

| Dryness modeСпособ засухи | Electrical sirocco dryingЭлектрическое высыхание сирокко |

3. SJ65/33Single Screw Extruder

| Screw, Barrel | Adopt 38CrMoAlA, Nitriding(HV720),PPR specialscrew with bimetal |

| Screw Diameter | 65mm |

| Screw Length-diameter Ratio | 33:1 |

| Main Motor Power | 37KW,FUJI |

| Barrel Heating Method | Foundry Aluminum Heater, include force coolingfan,(Suzhou SOK ) |

| Barrel Heating Power | 3.6KW×5 zone |

| Reducer Gearbox | ZLYJ200 Reducer Gearbox(gear’s surface is rigidity) |

| Main Electrical Equipment | Japanese OMRON Temperature Control Meter,Siemens Contactor,Shanghai TAYEE Button and Indicator Light,Suzhou ChuangShuan digital display meter |

| Capacity | 60~120kg/h |

4. SJ45/30 Single Screw Extruder

| Screw, Barrel | Adopt 38CrMoAlA, Nitriding(HV720),PPR specialscrew with bimetal |

| Screw Diameter | 45mm |

| Screw Length-diameter Ratio | 30:1 |

| Main Motor Power | 15KW,Simens |

| Barrel Heating Method | Foundry Aluminum Heater, include force coolingfan,(Suzhou SOK ) |

| Barrel Heating Power | 3KW×4zone |

| Reducer Gearbox | ZLYJ133Reducer Gearbox(gear’s surface is rigidity) |

| Main Electrical Equipment | Japanese OMRON Temperature Control Meter,Siemens Contactor,Shanghai TAYEE Button and Indicator Light,Suzhou ChuangShuan digital display meter |

5. SJ25/25 Single Screw Extruder(Marking Line)

| Screw, barrel | Adopt 38CrMoAlA, Nitriding |

| Screw Diameter | 25mm |

| Screw Length-diameter Ratio | 25:1 |

| Main Motor Power | 1.5KW |

| Main Motor Timing Method | Adopt 1.5KW Japanese FUJI AC Inverter |

| Barrel Heating Method | Adopt Stainless Crust,electro thermal wear heating |

| Barrel Heating Power | 1KW×3 Zone |

| Main Electrical Equipment | Japanese OMRON Temperature Control Meter,Siemens Contactor,Shanghai TAYEE Button and Indicator Light,Suzhou ChuangShuan digital display meter |

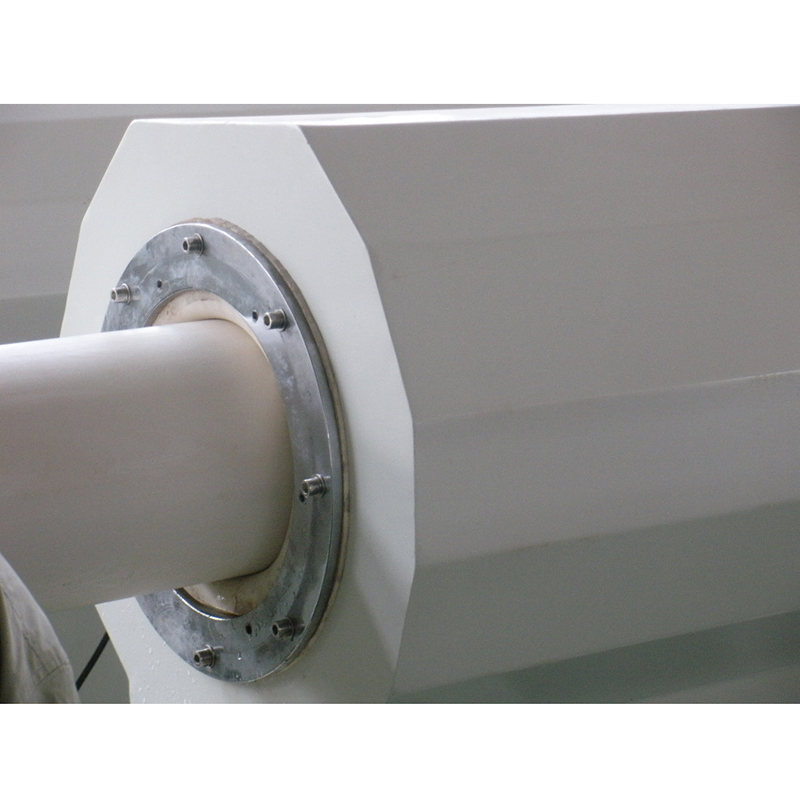

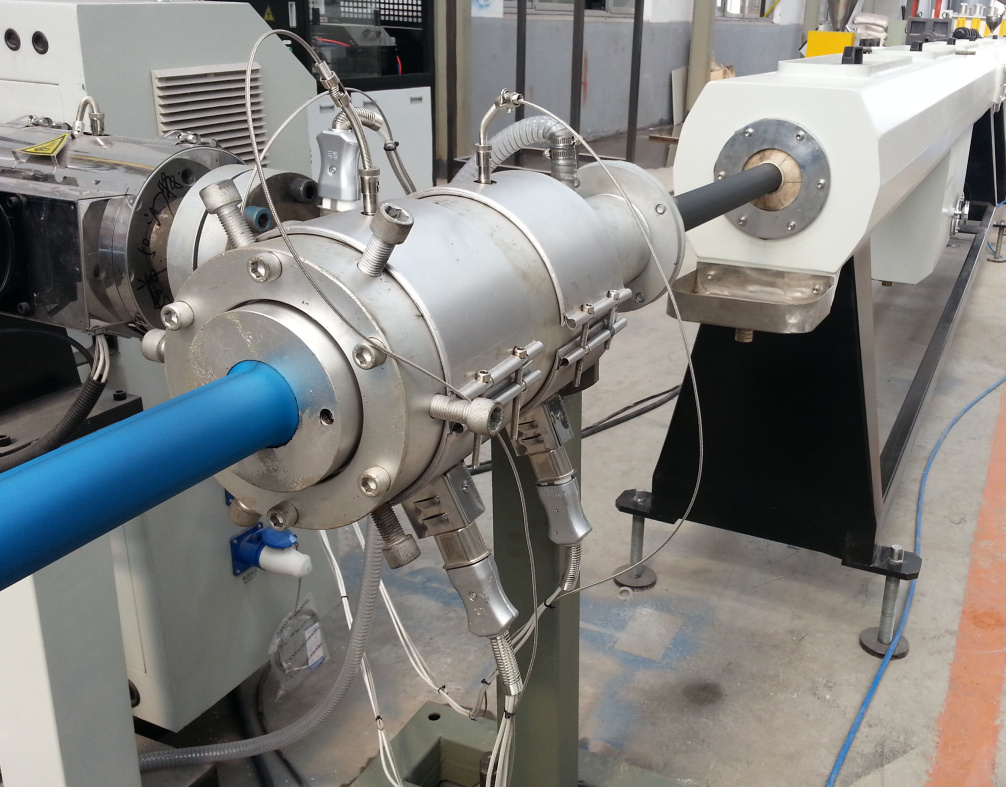

6. “Φ20~Φ63” PP-R Pipe Mould

| Mould Specification | Φ20,Φ25,Φ32,Φ40,Φ50,Φ63mmEquip three different pressure grade die core |

| Form | Blueness Die-head, water-film cooling |

| Mould material | 40Cr |

7. Vacuum Calibration Tank

| Calibration Tank Length | 6 Meter |

| Tank Material | Adopt 3mm(304) thickness stainless steel board |

| Vacuum Pump | 4KW×1pc |

| Water pump | 4KW×1pc |

| Tank Lengthways Move | Adopt 0.75KW Gearbox Speed Reducer Motor,Adjusting Distance equal to 800mm |

| Vacuum degree | 0~0.6Mpa |

8. Spray Cooling Tank

| Cooling Tank Length | 6 Meter |

| Water pump | 4KW×1pc |

| Tank material | Adopt 2mm(202)thickness stainless board |

9. Haul-off machine

| Haul-off Bracket Length | 1350mm |

| Haul-off Motor Power | 1.1KW×2pc |

| Haul-off Speed Adjusting | Adopt 2.2KW Japan FUJI AC Inverter |

| Haul-off Speed | 0.5~12meter/min |

| Above Haul-off Bracketcompaction Mode | Adopt Pneumatic gas cylinder |

| Maximal pull | 20000N |

10. No-scraps Cutting Machine

| Cutting Pipe Diameter | Φ20~Φ63 |

| Cutting mode | Revolution Motor drive blade surrounding PP-R pipe,simultaneity Pneumatic gas cylinder feeding blade,cut off PP-R Pipe, the smooth surface |

| Revolution Motor Power | 1.1KW |

11. Stacker

| Stacker LengthДлина | 4-5 meter4-5 метров |

| Laying Board MaterialНаложение Материала Правления | 0.8mm Stainless Steel Board0.8mm нержавейка |

| Stacking ModeСкладывая Способ | Stacking by Gas Cylinder,Adopt Limited Switch Send out Cutting SignalУкладка Газовым баллоном, Примите Ограниченный Выключатель, отсылают Сокращающий Сигнал

|

In addition to the characteristics of general plastic pipes such as light weight, corrosion resistance, non-scaling, and long service life, PP-R pipes also have the following main characteristics: 1 Non-toxic and hygienic. 2 Heat preservation and energy saving. 3 Better heat resistance. 5 Easy installation and reliable connection. 6 Materials can be recycled.