Plastic Window Door Profile Extrusion Machine

SJZ65/132 PVC Profile Extrusion Line

1. Project evaluation

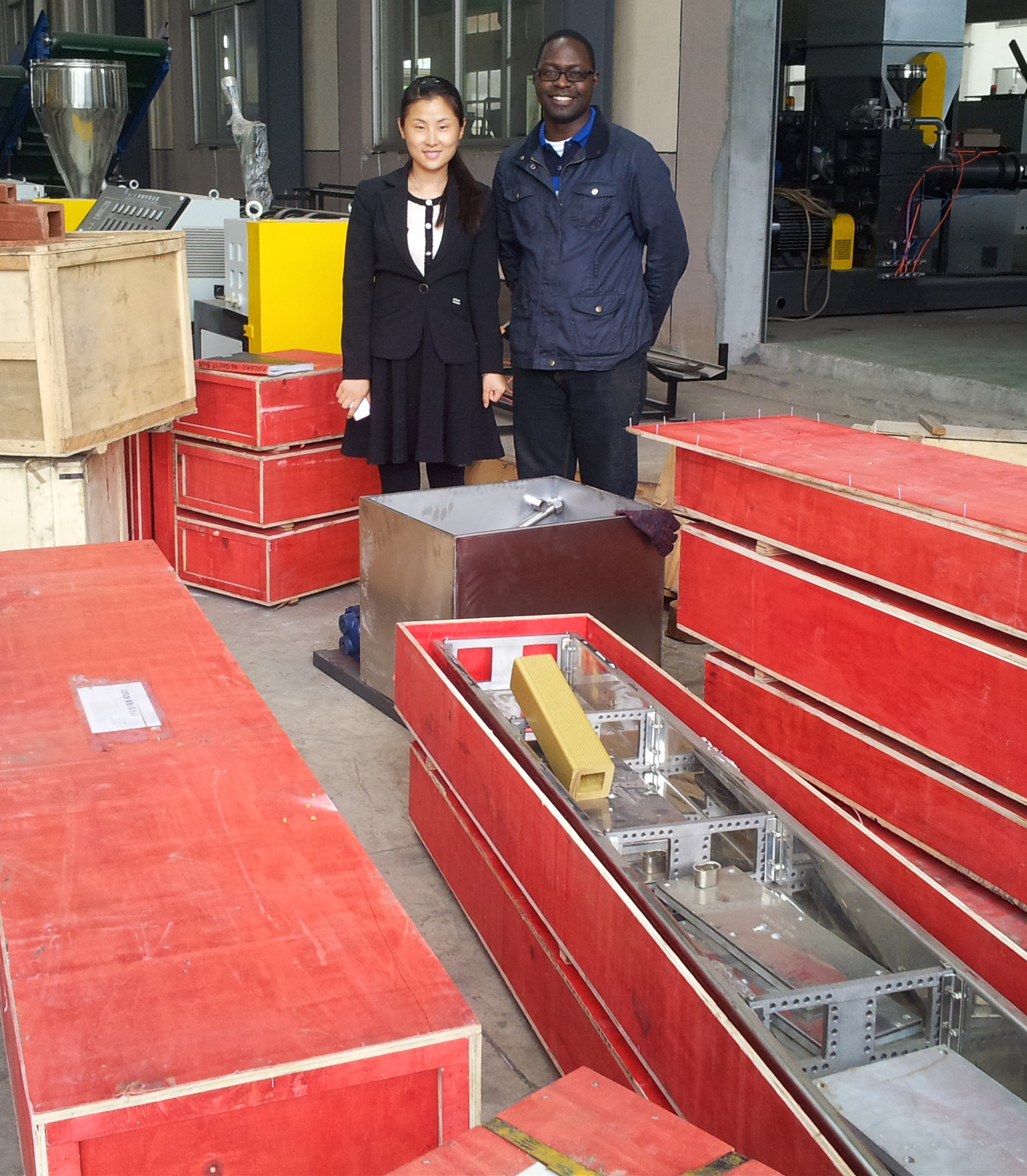

According to your requirement, we’d like to recommend our SJZ65/132 PVC Profile Extrusion Line. This extrusion line is composed of SJZ65/132 Conical Twin-screw Extruder and downstream assistant machine. Please check the below information:

1.1 Material characteristics

1.1.1 based material:

• PVC powder:

• CaCo3:

1.1.2 Additive:

• Coupling

• Lubricant

1.1.3 Material form

• All the material should be mixed completely.

Finished product: PVC Profile;

Output capacity: 150~250kg/hr (depending on finished product)

Infrastructure (Provided by customer)

a. Space for profile extrusion line in workshop:

About 22m (length)×2.5m(width)×3m(height) (Adjustable according to your factory. We ask you to show us the design draw of your workshop).

b. Electricity network: 380V/50Hz (Adjustable according to your local voltage standard).

c. Wire/cables: wires/cables from customer’s general control cabinet to the main control cabinet for profile extrusion line; all electrical cable from the main control cabinet to each machine.

d. Water supply: main water pipeline supply and water pipes to machines.

e. Means for lifting the machines when unloading and positioning.

f. Everything else not clearly mentioned above.

1.3 Energy consumption:

a. Electricity requirement

Total power installed: 100Kw;

Actual power consumption percentage: 80%;

b. Water requirement

8-10T/h and water can be circulated by means of a water pool (built by customer);

c. Manpower requirement

Max. Qty. of labors: 1-2 person;

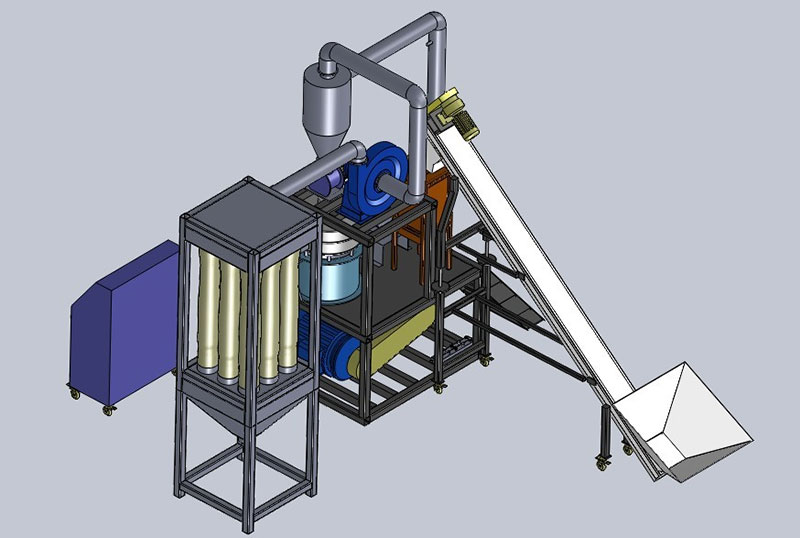

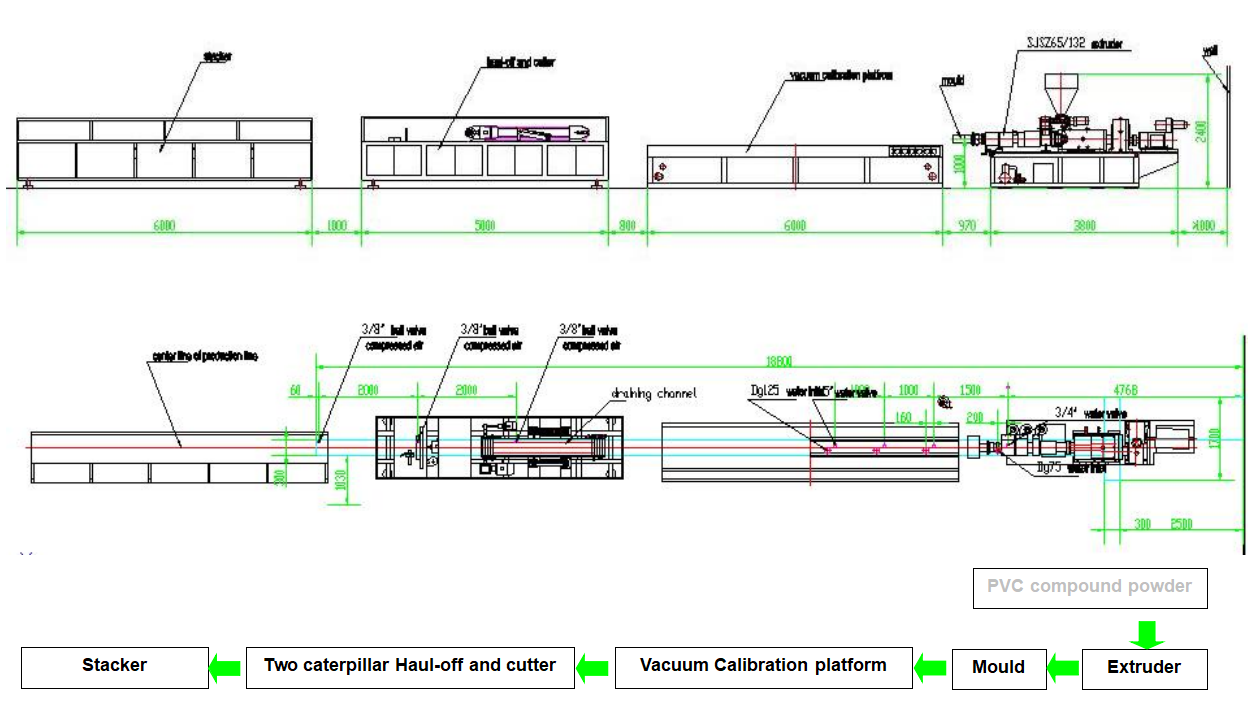

2. Flow line and configuration for PVC profile production line

3. Technical specification

SJZ65/132 PVC Profile extrusion line

|

No. |

Name |

Photo of machine | Qty. | Technical specifications | |

|

1 |

ZJ300 feeder |  |

1 |

Rated transmission capacity: 300kg/h | |

| Motor power: 1.5kwSpring diameter: Φ36mm

Material: Stainless steel |

|||||

|

2 |

SJZ65/132 conical twin-screw extruder |  |

1 |

2.1 screw2.2 barrel

2.3 driving motor 2.4 feeding system 2.5 Vacuum system 2.6 Adaptor 2.7 Main electric cabinet Self-protective system |

|

| 2.1 Screw : diameter conical 65/ 132 mm for PVC drainpipe and water supply pipe.Material of screw: 38CrMoAl

Surface treatment: Nitriding processing, thickness: 0.6 ~ 0,8mm, Polishing Rotating speed (counter rotating): 1-34.7 rpm/min 2.2 Barrel: diameter conical 65/132 Inner processing: nitrided with thickness: 0.6 ~ 0.8mm Heating zones: 4 Heating mode: Cast alumina + stainless steel covering Heating power: 22kw Cooling mode: Air fans: 3 Sets 2.3 Driving motor: Motor power: 37Kw Type of motor = AC 2.4 Feeding system: Gravity and screw dosing feeding system With stainless steel hopper Dosing feeding system: Motor: 1.5Kw Feeding sleeve with circular water cooling 2.5 Vacuum dehumidifying system: Vacuum pump: 1 set Vacuum degree = 0 ~ 0.075 Mpa 2.6 Adaptor: (Interflow Section): Material: #40steel Chrome plated, inner convergent flow type Connection method with die: clamping block + bolt Pressure melt sensor and thermocouple 2.7 Main electric part supplier : Inverter: ABB or DELATA Contactor: Schneider or SIEMENS Air Switch: Schneider Relay: Omron Temperature controller: RKC 2.8 Self protective system: Over current protective of motor Over pressure protective of screw. |

|||||

|

3 |

YF240 Calibration platform |  |

1 | 3.1 Exterior dimension3.2 Vacuum pump

3.3 Water pump 3.4 Three direction adjustment: Contact water part are made by stainless steel. |

|

| 3.1 Exterior dimension:Lx W x H: 6000x1100x1000mm (adjustable)

3.2 Vacuum pump: Vacuum pump: 3x5.5KW; Origin: Yuanli, China 3.3 Water pump: Water pump: 1×4KW; Origin: Guangzhou, China 3.4 Three direction adjustment: Forward and Backward with 0.75 Kw motor Range: ±1000mm Up and down, left and right manually adjusted Range: up and down: ±150mm LEFT and RIGHT moving: ±50mm |

|||||

|

4 |

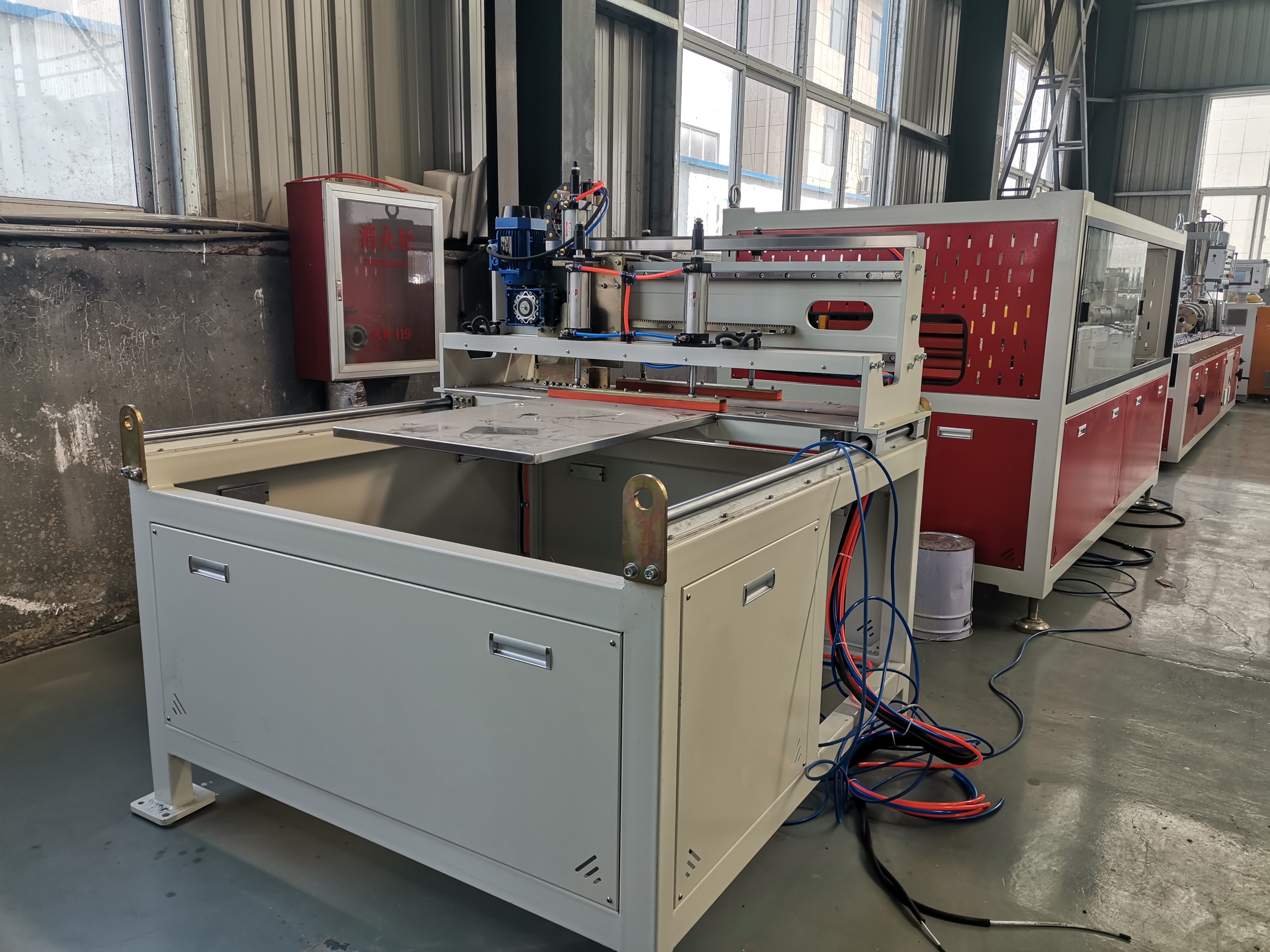

DYⅢQ Haul-off and cutter (combined) |  |

1 | 4.1 Haul-off4.2 Cutter | |

| 4.1 Haul-offHaul-off speed: 0-3m/min;

Motor power: 5.5KW; Caterpillar width: 210mm; Caterpillar length: 2200mm; Pneumatic clamp; Adopt holip or ABB inverter; 4.2 Cutter Motor power: 2.2KW; Scrap collecting motor power: 1.5KW; Diameter of saw: 500mm; Cutting range: 200mm; With scrap collecting device;

|

|||||

|

5 |

Tipping table/Stacker |  |

1 | 5.1 Tipping table:Length

Control method Height adjusting range |

|

| Length: 6,000mmControl method: Pneumatic

With screws to adjust the height range: 0 ~ 180mm |

|||||