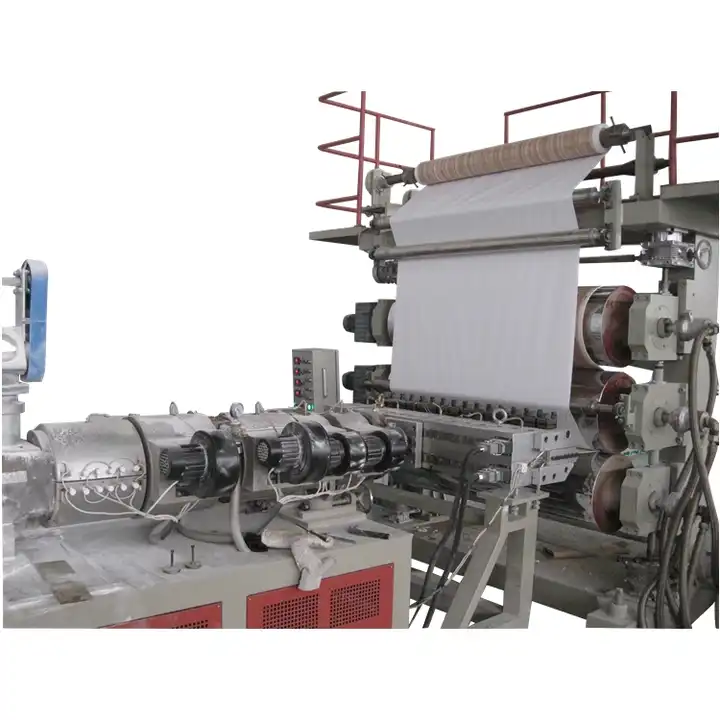

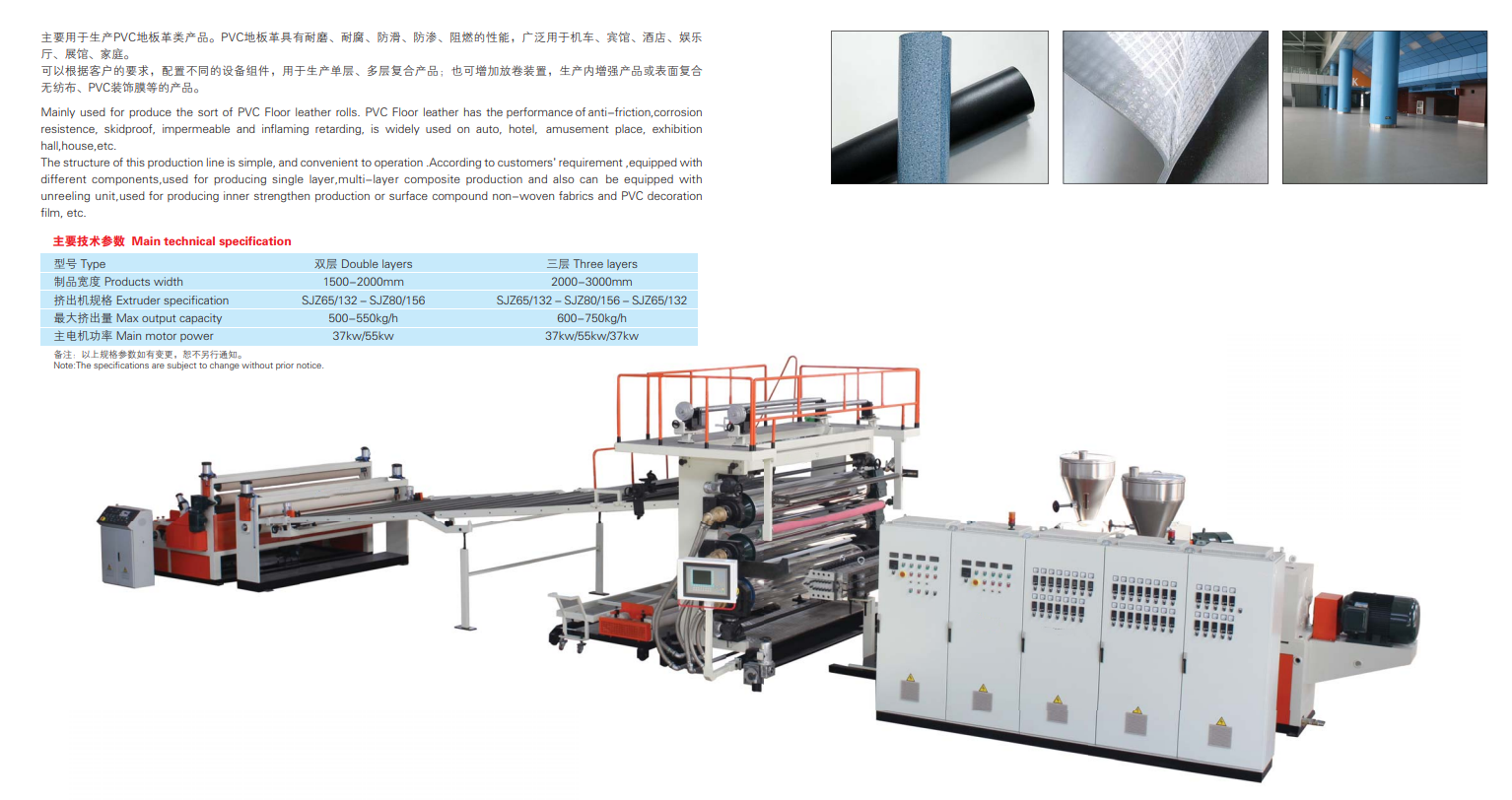

plastic PVC sheet board extrusion line

Specifications

|

SJSZ-80/156 CONICAL TWIN SCREW EXTRUDER UNIT |

||||

|

Item |

Name of equipment |

Quantity |

Price |

Remark |

|

1 |

SJSZ-80/156conical twin screw extruder |

1 set |

power of main engine:55 or 75Kw |

|

|

2 |

Reducer, gear box |

1 set |

||

|

3 |

Electric controlling |

1 set |

||

|

4 |

Three Roller Calender |

1 set |

||

|

5 |

Bracket with tractor one machine |

1 set |

||

|

6 |

Cutting machine |

1 set |

||

|

7 |

Bracket |

1 set |

||

|

8 |

PVC panel mould |

1set |

Width:1200mm Thickness:0.2-2mm According customers samples |

|

|

Auxiliary Devices |

||||

|

Item |

Name of equipment |

Quantity |

Price |

Remark |

|

1 |

SWP 450 crusher |

1 set |

power :18.5kw |

|

|

2 |

SHR-L300/600 high speed cooling mixer |

1 set |

double speed motor power:40/55kw |

|

Technical dates

1, SJZ80/156 conical twin screw extruder 1 unit

Screw diameter: 80mm, 156mm

Screw design special for PVC blend, Max. extrusion capacity 350kg/h

Screw and barrel material are 38CrMoAlA with nitrided treatment

Screw nitrided layer thickness is 0.4-0.6mm, hardness is 740-940, surface roughness is less than 0.8um

Barrel nitrided layer thickness is 0.5-0.7mm, hardness is 940-1100, inner wall roughness is less than 1.6um

Barrel heating by ceramic heaters with stainless steel shield, 4 zones, total 36kw, cooling by fan with medium air, screw inner cooling by cycling oil system

Gearbox, transmission by helical gears, material 20CrMoTi, carburized and grinded, gears in distribution box material 38CrMoAlA, nitride, shaft material 40Cr, bearings by NSK, Japan

AC motor by Siemens , made in China, power 55kw

Inverter by ABB

Temperature control by Japan RKC, temperature surveying by thermocouple, with pressure indication, main electric components by imported name brand, like contactors by Schneider

Vacuum venting system

Vacuum pump power: 2.2kw

Automatic urgency stop protections:

1, overcurrent, overload

2, photoelectricity protection when screw displacing

3, oil shortage

Dosing feeder

Motor power 0.55kw, governor

Screw loader

Central height: 1100mm

2, T-die 1 unit

T type die head, clothes-hanger type melt flow sprue

Sheet width 1400mm, thickness 0.2-1mm

3, Roll stack 1 unit

3, Roll stack 1 unit

Vertical type

Rollers

Roller 1 Φ1500mm*400mm

Roller 2 Φ1500mm*400mm

Roller 3 Φ1500mm*400mm

Type: two shells, with spiral flow channel inside

Material: 45# steel

Surface heat treatment: chrome plated, polished

Chrome layer thickness: 0.10mm

Surface hardness (after chrome-plated): HRC52-55

Surface roughness: Ra<=0.025um

Bearings NSK, Japan

Drive

Gearbox: Rexnord

AC motor, power 1.5kw

Gap adjustable between rollers

Up and down adjustment by hydraulic, slight adjustment by worm wheel and worm (manual)

Gap indication: micrometer

The clender to be installed on the rails, longitudinally moveable (by worm wheel and worm(manual or electric drive))

Rotational joint

4, Temperature control system for roll stack 1 unit

3 units individually

Cooling medium: soft water

Temperature control range: 35℃-100℃

Heating power: 12kw*3

Pump power: 3kw

Electromagnetic valve control

5, Roller bracket 1 unit

Length: 6m

Aluminum rollers, Φ70×1500㎜, with their surface oxidized, polished

Side trimming: three blades, opposite distance, position adjustable

6, Haul-off unit 1 unit

One pair of rubber rollers, size Φ250×1500㎜

Gearbox: Rexnord

AC motor, power 1.5kw

Inverter: Danfoss

Synchronization control with roll stack

7, Winder 1 unit

Type: by friction

Air shaft 3”

8, Electric control system

Electric cabinet vertical type

With vent

Main electric components are imported name brand

Extruder ABB

Temperature control RKC

Roll stack, haul off unit Danfoss

Contactors Schneider

Contactors(heating sections) Omron, SSR

Air switch schneider

9, CJ-HL300/600 hot and cooling mixer 1 unit

Total volume 300/600L

Working volume 225/450L

Motor power 40/55/11kw

Heated by electric and self friction

Cooled by water