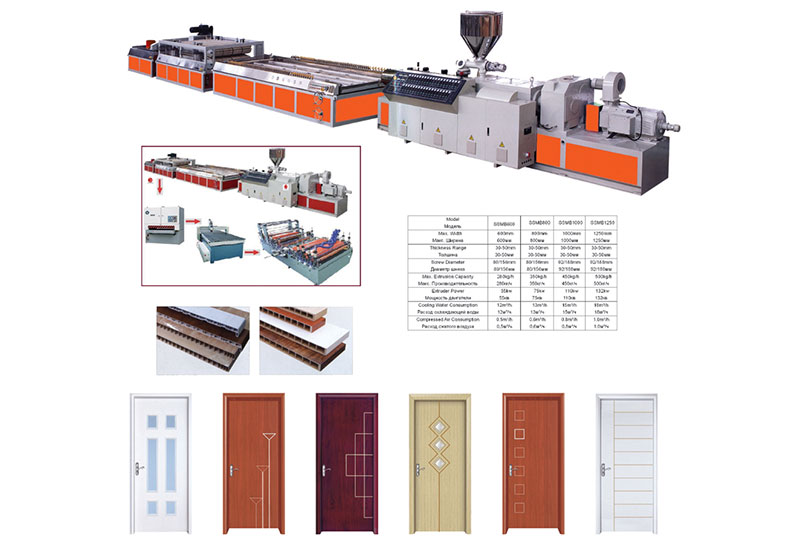

Plastic PVC Electrical Cable Trunking Profile Extrusion Line

Basic Information

>> Use: For production of soft PVC profile, rigid PVC profile, soft-hard co-extrusion profile,foam profile extrusion, multi layer co-extrusion etc.

>>Process Flow: Screw Loader →cone / parallel Twin Screw Extruder/Single screw extruder → Co-extrusion machine → Mould →Calibration Table → Haul-off & Cutter →Tripping Table → Final Product Inspecting & Packing

Conical twin screw extruder

The solid material is plasticized and fused into a uniform temperature melt and continuously extruded

- World famous brand electrical component such as Siemens,Schneider, ABB etc;

- High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service;

- Bimetallic screw and barrel;

- Intelligent PLC controlling system with human-friendly interface.

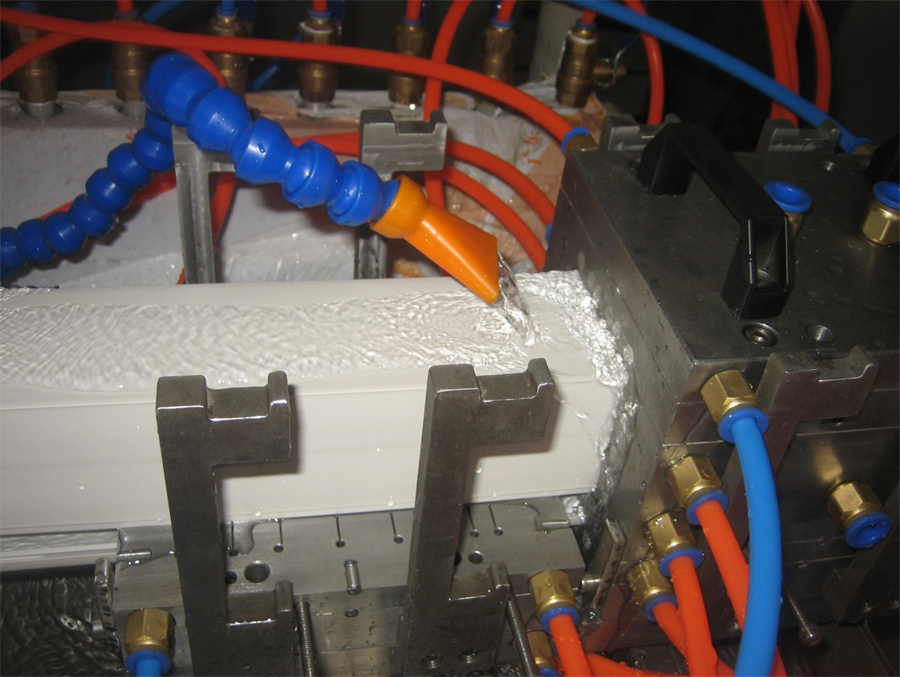

Extrusion mould

Change the shape of the molding material through the mold

- 3Cr13/3Cr17 material;

- Complete set include extrusion die head, calibrator and cooling tank;

- Apply to soft PVC, rigid PVC, soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

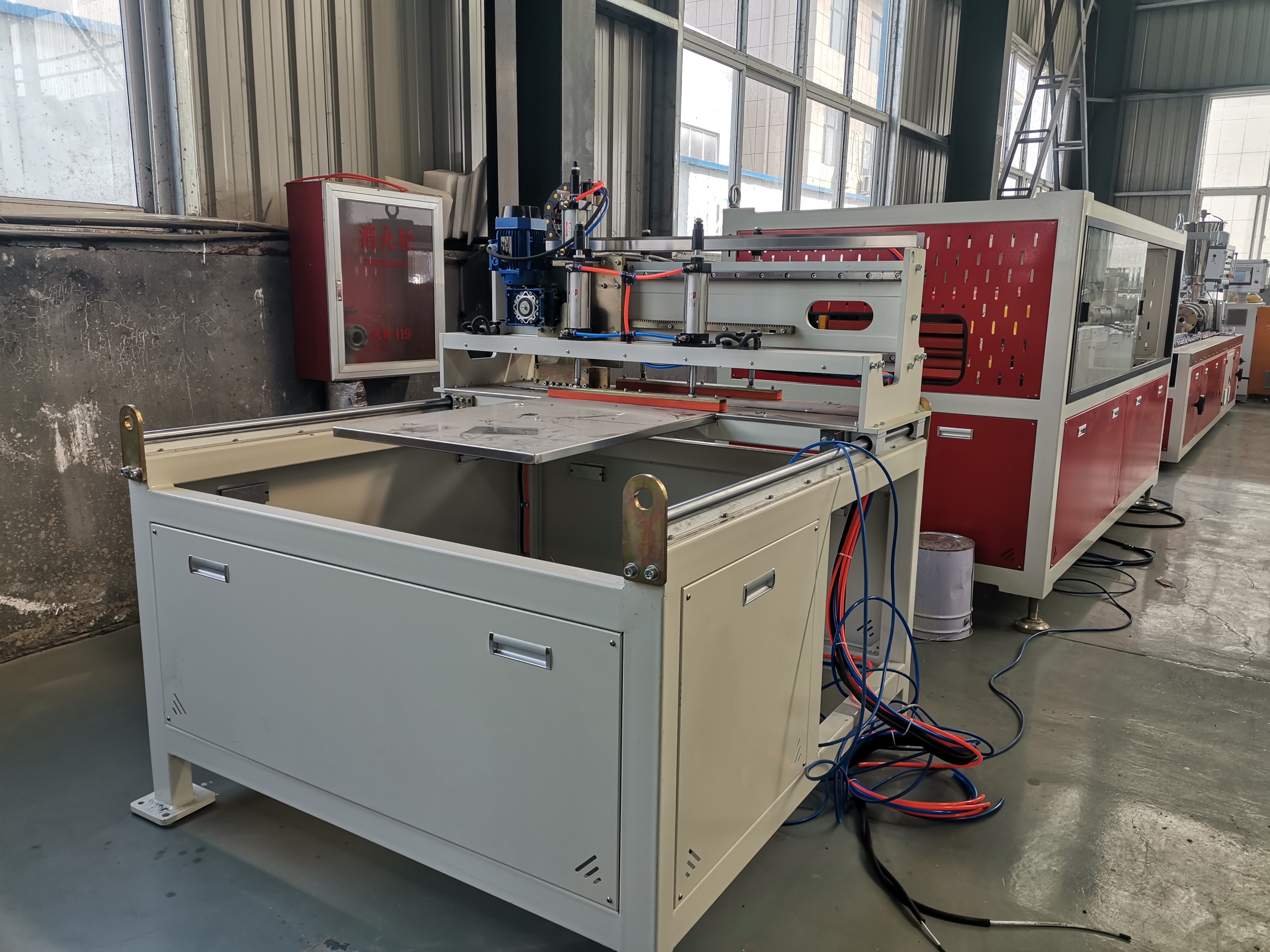

Vacuum Calibration Table

After exit from the die head, enter the cooling mold immediately. The mold is vacuized, so that the outer wall of the profile and the surface of the molding mold are tight, and the water is cooled by the molding sleeve. The adsorption force of the vacuum is required and uniform, so as to ensure the appearance and dimensional precision and apparent quality of the profile.

- Include full set of vacuum and water pump;

- Length from 4m-8m;

- Independent operation panel for easy operation.

Caterpillar Haul off machine

After the extruder extrudes the raw material through the mold. The tractor clamps the profile from its outlet and then pulls it to a certain length, which reaches the predetermined extruded length

- Upper and lower caterpillar is driven separately and speed control by frequency inverter;

- Fast change type pads for easy operation;

- Install plate is adopts aluminum material;

Product collection stacker

Collect and arrange the cut product

- Stainless steel304 as touching material;

- Discharge driving by air cylinder.

Product Paramenters

|

Max profile width (mm) |

Extruder model |

Designed capacity(kg/h) |

Extruder motor power(kw) |

|

180 |

51/105 or 55/110 |

80-120/120-150 |

18.5/22 |

|

240 |

65/132 |

175-250 |

37 |

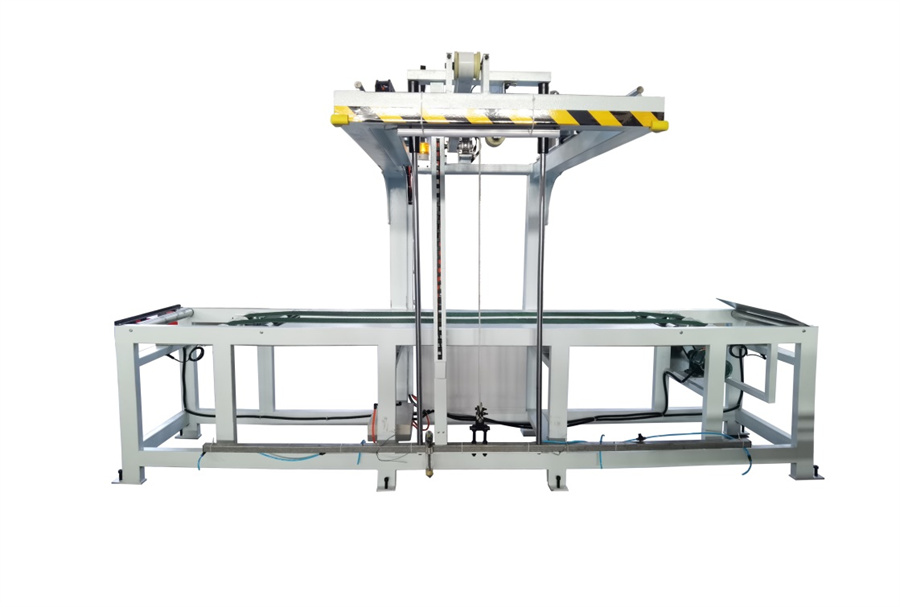

Manipulator

The grasping and unloading plate manipulator is composed of a vacuum suction cup device, a lifting device and a moving device.

It is used for the composite movement of vertical lifting movement and horizontal movement, for picking up finished plates and profiles and arranging blank plates. The device realizes the automation of plate conveying.