Pelletizer/pelletizing recycling machine

Process flow

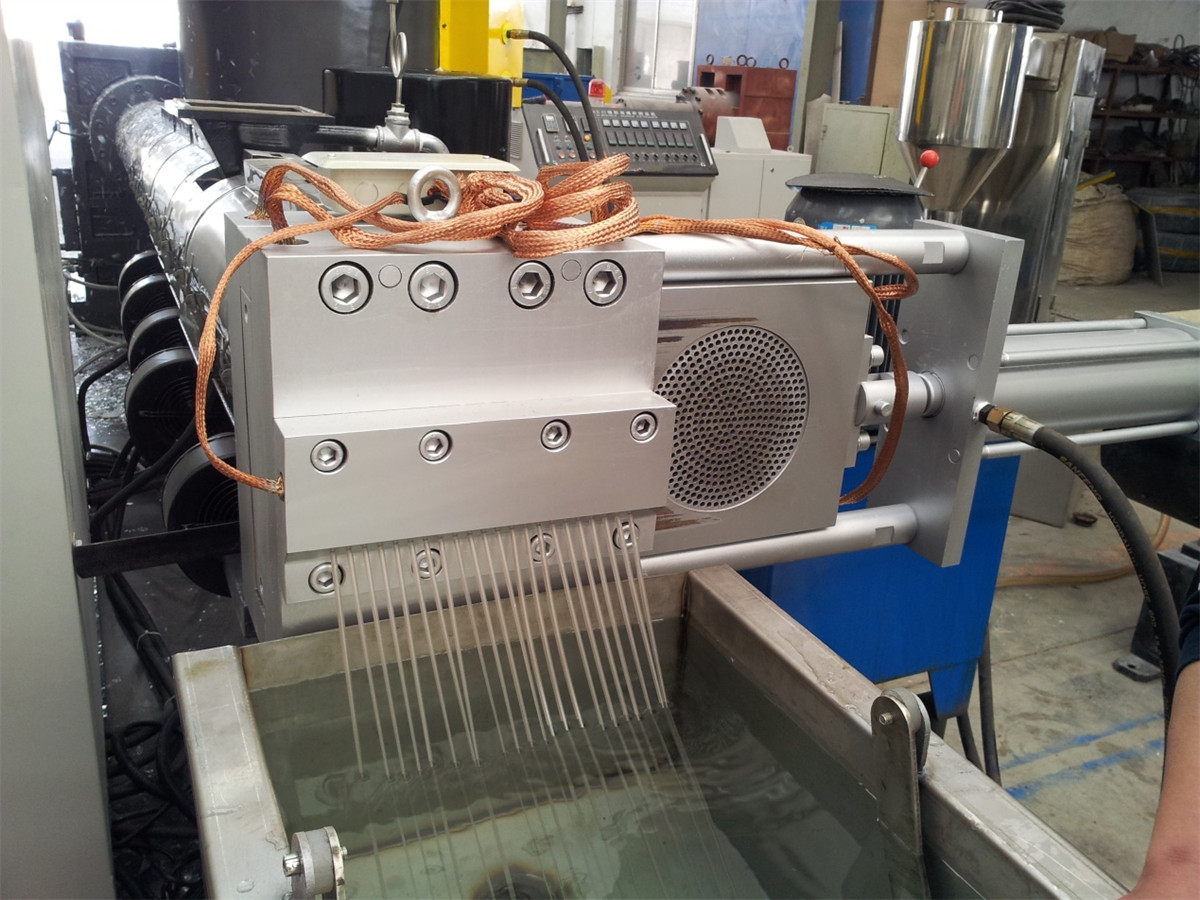

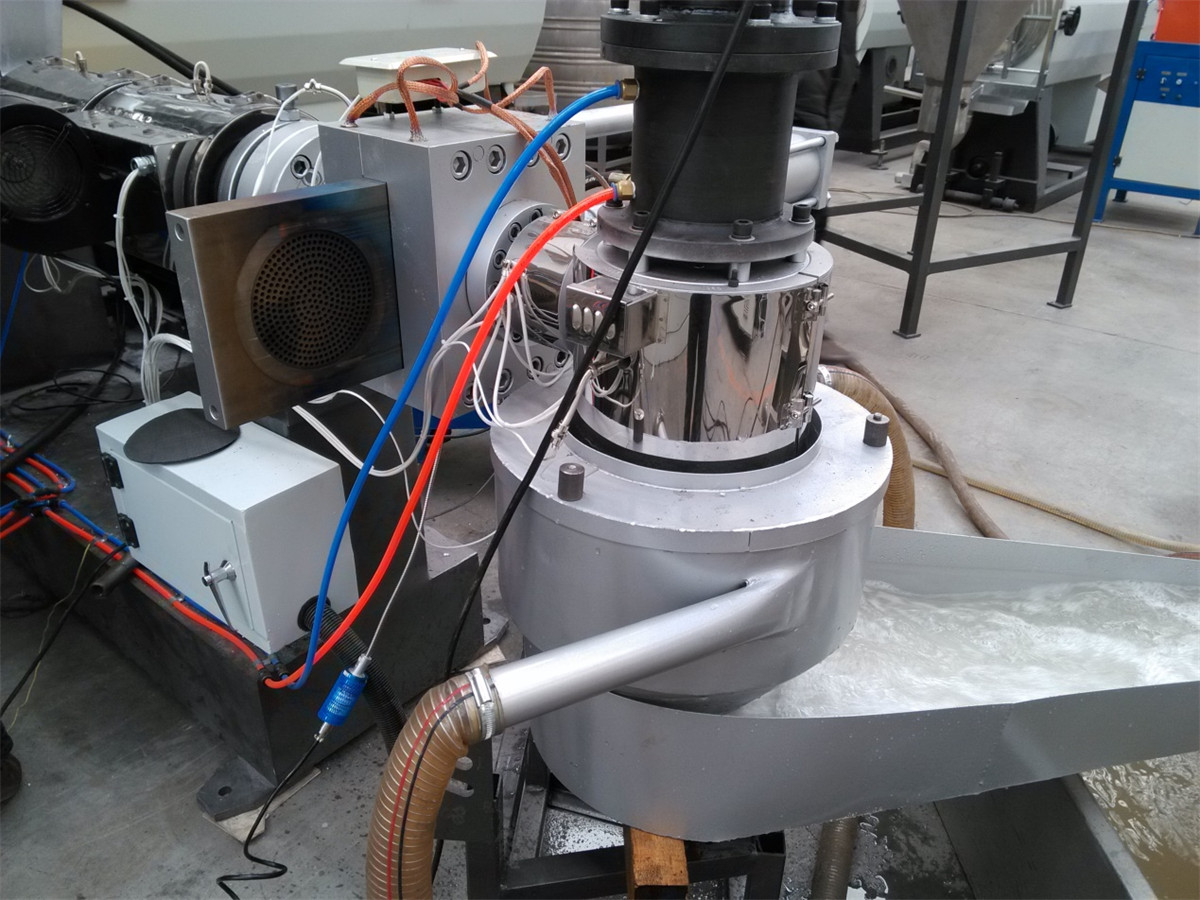

Screw feeder ( OPTIONAL)→ Force feeder→1# Degassing screw extruder →1# Hydraulic filer exchanger→2# screw extruder →2# Hydraulic filer exchanger→ Mould head →Water ring cutting →Dewatering machine→ Air dryer Blowing system→ Storage hoper→ Finished product packing.

We can do Production line for Granule from ABS/PC/PP/PE/PVC/ WPC according material and output we have below design :

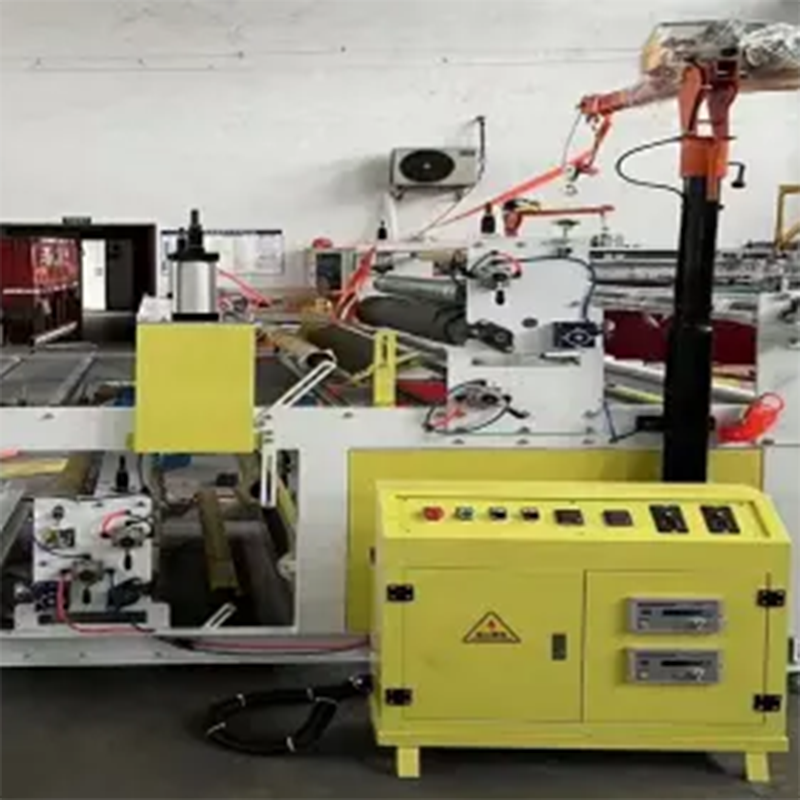

PP PE waste plastic film recycle pelletizing machine line plastic film granulator

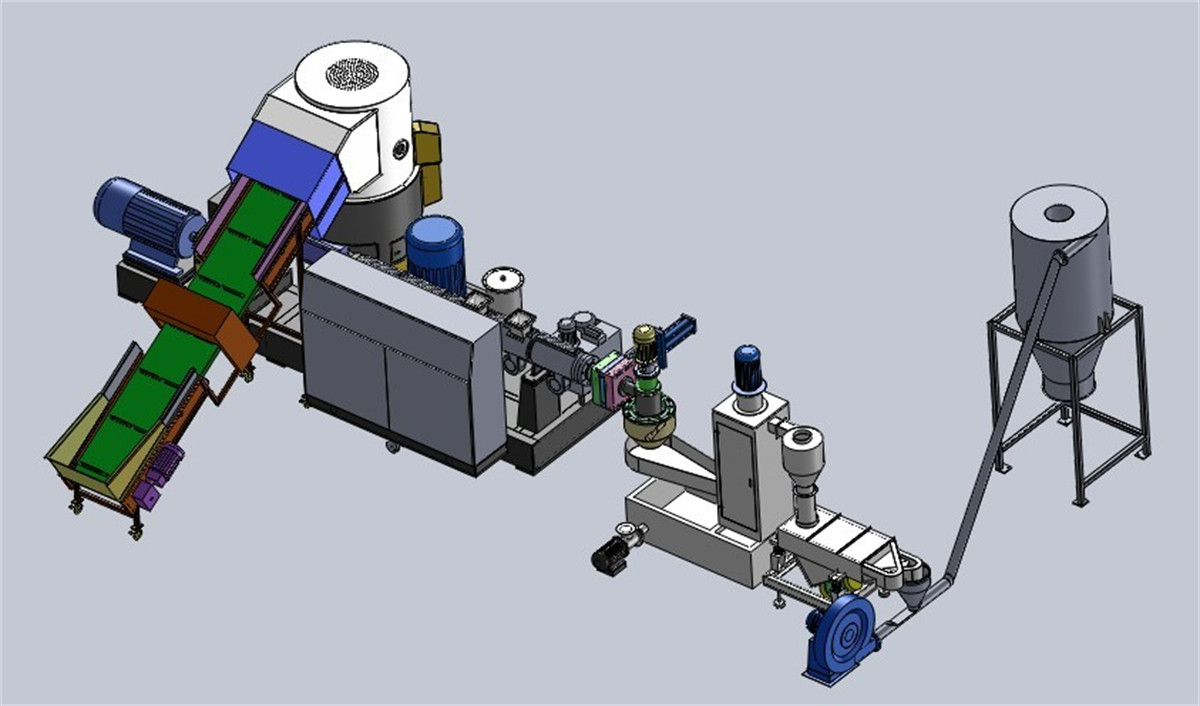

Flow chart of PP/PE scraps pelletizing line

The process flow of PP/PE scrap pelletizing line is as following:

Screw feeder →Extruding system→ High speed Net exchanging system→ water ring pelletizing machine→ water troughdewatering machinevibrating sieve air blower system → Storage

200kg/hour PE/PP scraps Pelletizing line

Product list

- 1 set of plastic crusher

- 1 set of air blower feeder

- 1 set of screw feeder

- 1 set of side force feeder

- 1 set of screw feeding dosing machine

- 1 set of SJ100/30 Extruding Machine

- 1 set of high speed Net exchanging system

- 1 set of water-ring pelletizing machine

- 1 set of water trough

- 1 set of dewater Machine

- 1 set of vibrating sieve

- 1 set of air blower system

Applications

Double-stage reclaimed pelletizing production line is the ideal equipment for plastic pelletizer, especially for PP, PE film waste, HDPE, PP, BOPP, HDPE, LDPE, LLDPE, ABS, EPE, EPS, XPS, stretch film Non-woven fabrics, woven bags, solid materials recovered, crushed material recovery and granulation. The production line has the advantages of novel design, reasonable structure, stable operation, low noise, low power consumption and high output.