PE PVC Single Wall Plastic Corrugated Pipe Machine

Product Detail

Detailed description of the plastic single wall corrugated pipe machine

1, Material for the single wall corrugated pipe and corrugated tube:

This production line can be used to produce corrugated pipes of PE,PP,PVC,EVA continuously ,as well as PA corrugated pipes

2, Application for the single wall corrugated pipe and corrugated tube:

Plastic single-wall corrugated pipes have feathers of high temperature resistance, resistant to corrosion and abrasion,high intensity,good flexibility,etc.They are widely used in fields of auto wire,electric thread-passing pipes,circuit of machine tool,protective pipes of lamps and lanterns wire,tubes of air conditioner and washing machine,etc.

3, Advantages of the single-wall corrugated pipe machine (the machine for corrugated tube):

This production line with good performance and reasonable price,it will be the best choice for your producing single-wall corrugated pipe.

| plastic single wall corrugated pipe machine Machine list | Quantity |

| SJ65/30 single screw extruder with auto feeder and drying hopper | 1 set |

| Die head | 1 set |

| Mold: 72/90 pairs of mold blocks | according to customer's requirements |

| Steel wire unwinding and inserting device | 1 set |

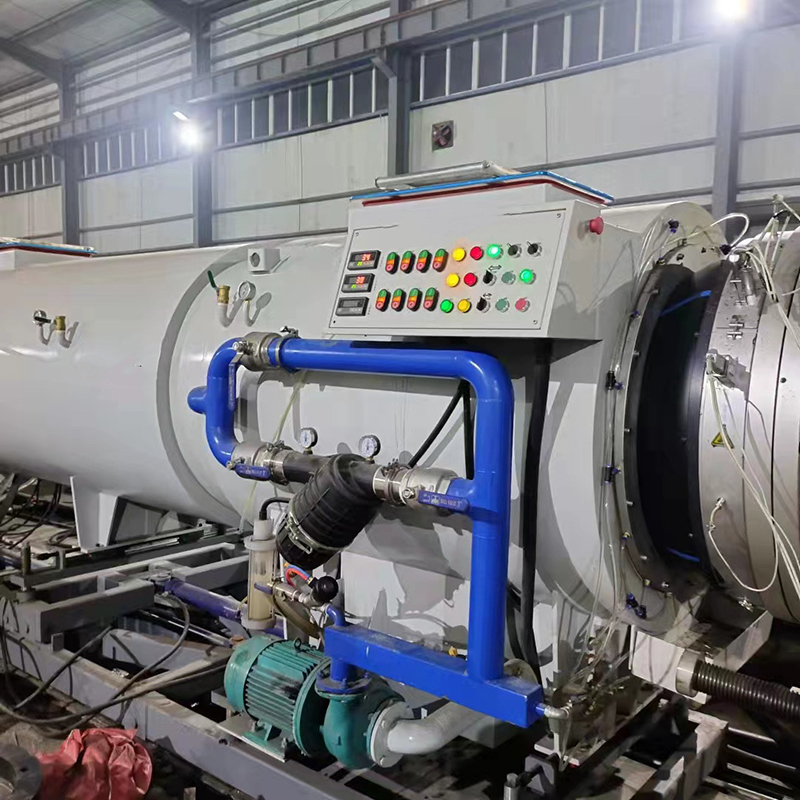

| Forming machine: with water cooling | 1 set |

| double station winding machine | 1 set |

| Electricity control system | 1 set |

| Spare parts | 1 set |

Images of Single Wall Corrugated Electric Wiring Pipe Make Machine:

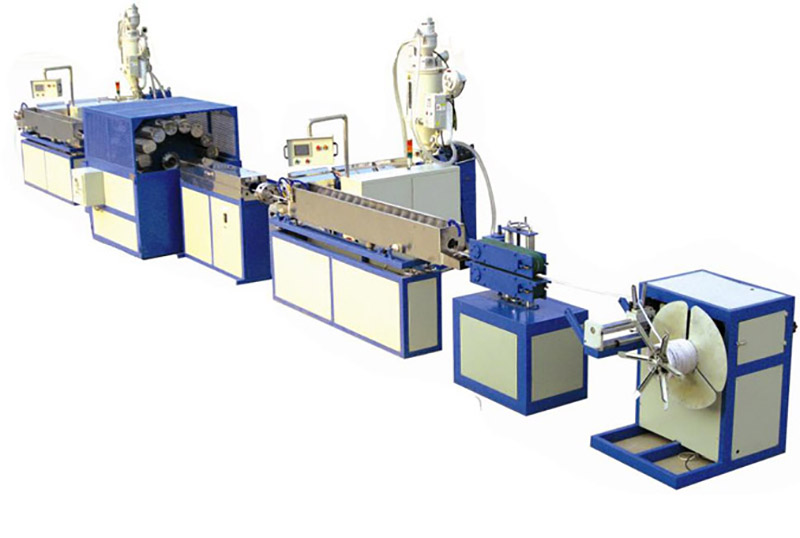

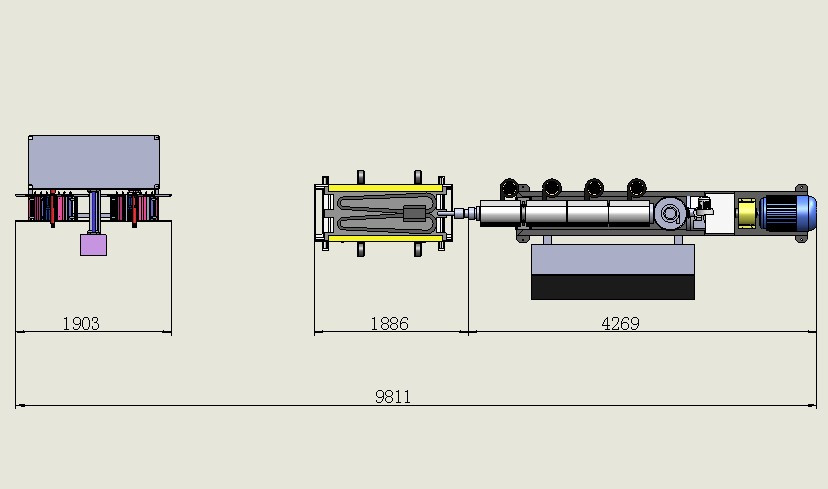

1. Extruder:

Mainly use SJ-45 extruder or SJ-65 extruder, which can keep a stabile output and save the energy. The SJ-45 extruder for making 9-32mm diameter corrugated pipe, and SJ-65 extruder for making 32-110mm. The L/D can be different according your material and different output.

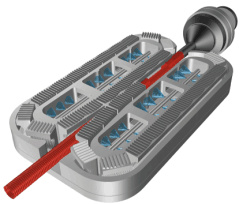

2. Corrugated Pipe Molding Machine:

This mahcine is used to shape the corrugated pipe. The mould can be discharged and changed. Corrugated pipe diameter is decided by the mould, so if you want to process different diameter, you should change differnet mould. Our factory can also provide you with the mould.

3. Coiling Machine/Winding machine:

This machine is used to reel in and packing of corrugated pipe. With electric control system it can control reeling speed accurately. And it can also control the size of reeling. It is very convenient for discharging. This machine also is widely used in other soft pipe making lines.

|

Item |

Description |

Unit |

SJ65/30 |

|

|

|||

|

1 |

Screw diameter |

mm |

65 |

|

2 |

L: D |

|

30:1 |

|

3 |

Motor power |

KW |

AC30 |

|

4 |

Brand motor |

|

Siemens |

|

5 |

Motor speed adjusting mode |

|

Frequency conversion |

|

6 |

Inverter |

|

ABB |

|

8 |

Extrusion output |

Kg/h |

50-75 |

|

9 |

Material of screw and barrel |

|

38CrMoAlA,Nitrogen treated |

|

10 |

Nitrogen depth |

mm |

0.5-0.8 |

|

11 |

Heating power |

KW |

4 zones, 14kw |

|

12 |

Cooling power |

KW |

4 zones, 250w×4 |

|

13 |

Gear box |

|

Hard gear surface, low noise design |

|

14 |

PLC touch screen: Siemens, screen size: 10inches |

||

|

15 |

Contactor |

|

Schneider |

Die head & forming machine & forming mould

| Die head | ||

| 1 | Die head material | 40Cr |

| 2 | Inner structure | Spiral type |

| 3 | Melt pressure meter | Equip with a pressure meter to monitor the melt pressure in the die head |

| Forming machine & forming mould | ||

| 1 | Material of forming mould | 40Cr, nitrogen treated |

| 2 | Forming mould | 7sets forΦ16, Φ20, Φ25, Φ32, Φ40, Φ50, Φ63 |

| 3 | Quantity of mould block | 60 pairs(4pairs as spare parts for each size) |

| 4 | Forming machine type | Horizontal type |

| 5 | Forming mould moving way | Circle |

| 6 | Drive motor power | 4kw |

| 7 | Inverter | ABB |

| 8 | Cooling way | Air cooling |

| 9 | Power of blower | 180w×5 |

Double disk winder

Application

1. Electrical wire conduit pipe

2. Automobile wire harness tube

3. Shisha hookah pipe

4. Washing machine drain hose

5. Air conditioner outlet pipe

6. Medical breathing tube

7. Extension tube