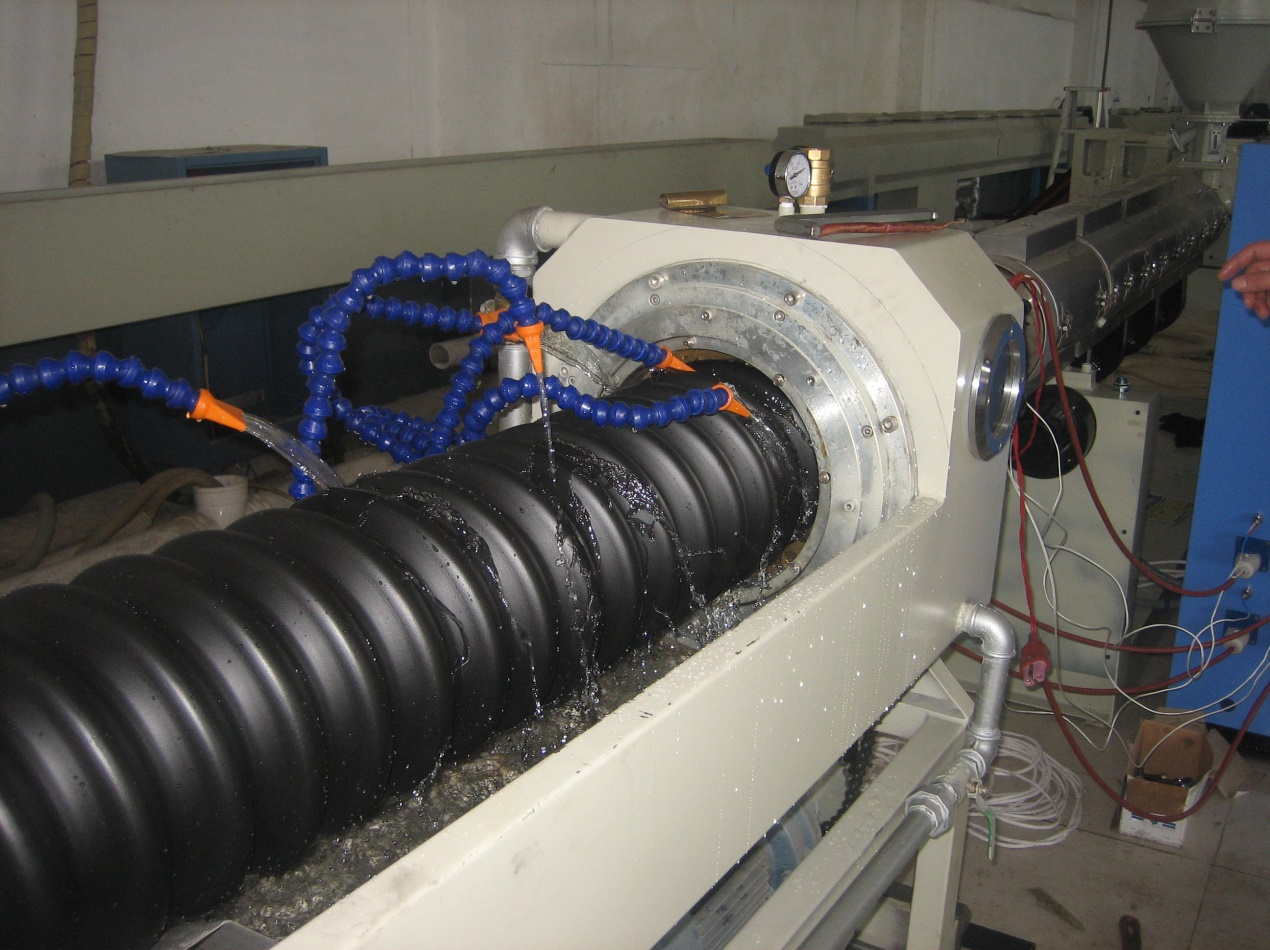

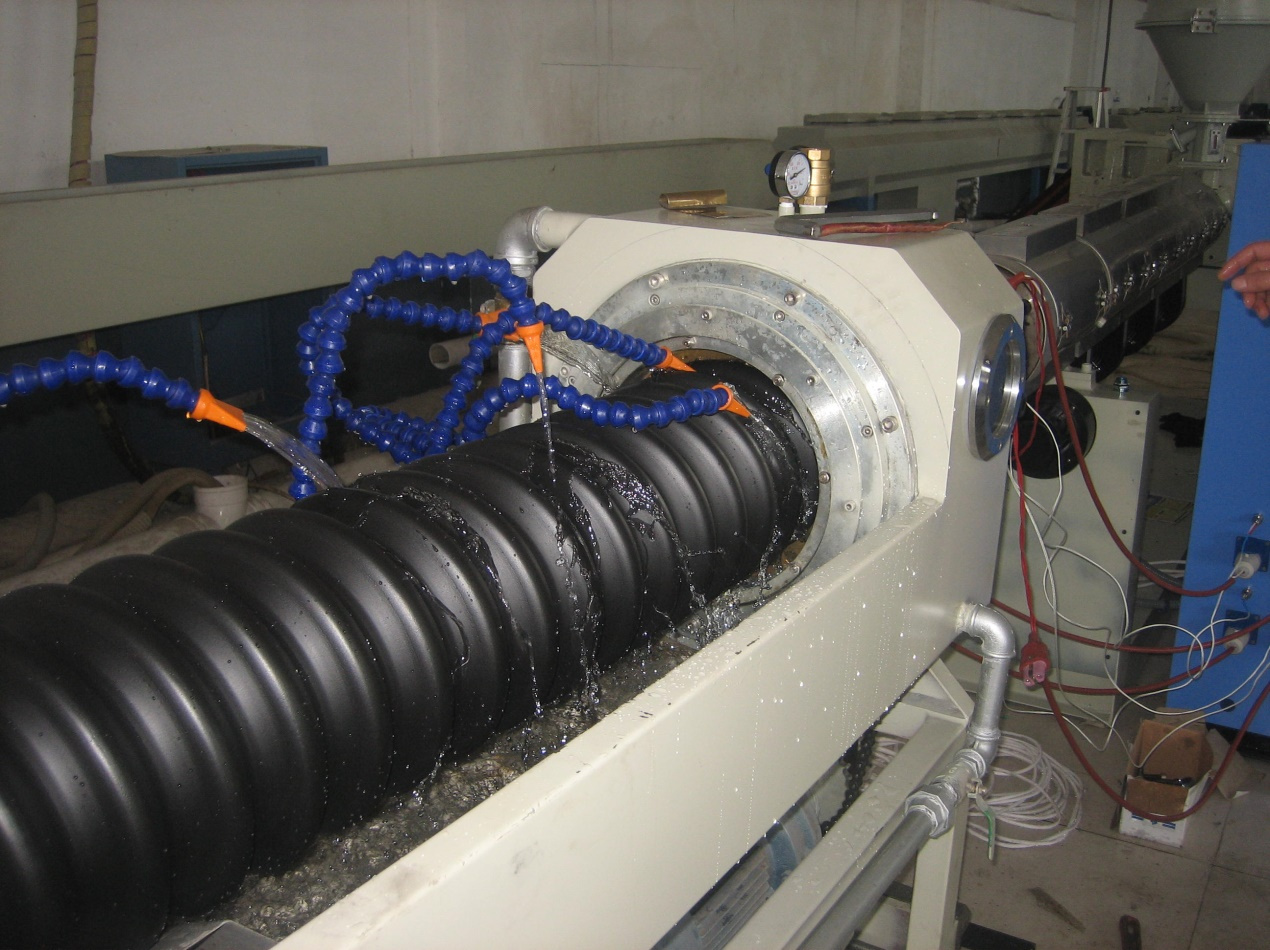

PE Carbon Composite Spiral Pipe Extrusion Line

Main technical parameter

The spiral corrugated pipe product has special spiral physical structure, the pipe material mechanical performance is good, the compressive strength, pipe buried under deformation, inner spiral uniform cable around the cooling efficiency and effectively protect the security of the cable.

Also the pe spiral pipe machine by changing the sleeve can produce the pe carbon spiral pipe machine

I. Main Machine SJ-65/30 Single-screw extruder 1 unit

Screw diameter Φ65mm

L/D 30:1

Screw material 38CrMoALA high-quality alloy steel, nitriding, surface treatment

Charging barrel material 38CrMoALA high-quality alloy steel, nitriding, surface treatment

Screw form two-step special protective screen BM-type compounding design

Charging mode atuomatic vacuum feeding

Gear change mechanism horizontal type gear reducer(made in Jiangying Reducer Factory)

Variable frequency motor Huali in Shandong

Motor power 45KW

Speed regulating mode frequency control (Fuji made in Japan)

Low-voltage apparatus made in China

Temperature controller RKC in Japan

Charging barrel heating cast aluminum electric heater

Heating and blower cooling section section 4

Heating power 25KW

Way of temperature control digital intellectual automatic temperature control

Max output 100kg

II. Extruder Head 1 set

Heating section section 3

Heating way stainless steel electric heater

Neck ring mold temperature control stepless voltage regulating temperature control

Heating power 4KW

III. Forming Die 2 sets

Die specification φ100mm fitting and mould

Die form helicism

Die material cast copper, surface polishing

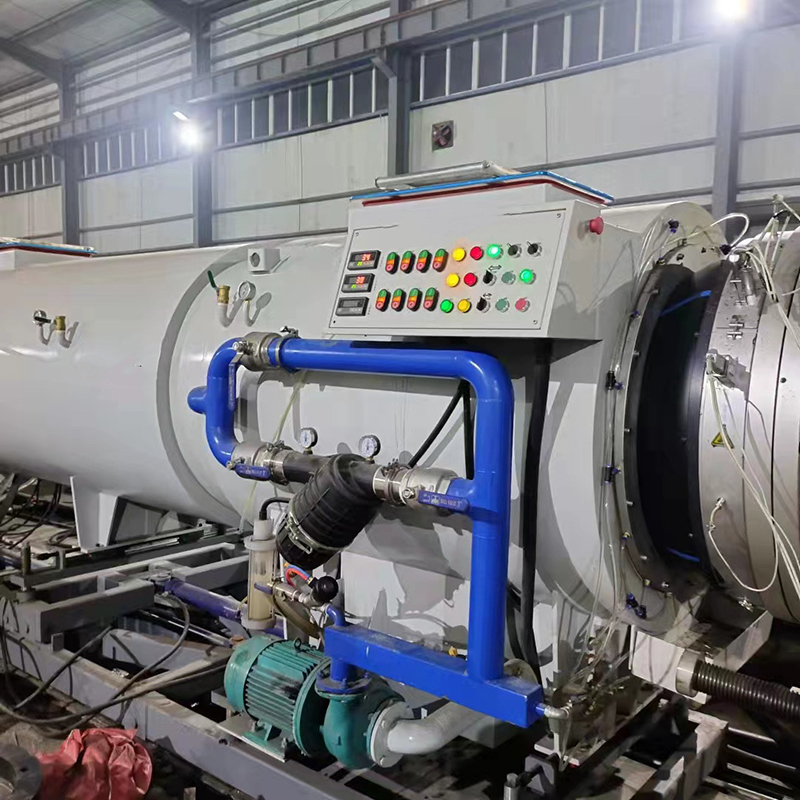

IV. Pipe Forming Machine 1 unit

Forming way vacuum forming

Vacuum pump power 5.5KW

Centrifugal pump power 3KW

Transmission power 3KW

Speed regulating mode frequency control (Fuji made in Japan)

Azimuth regulating three dimensions regulating

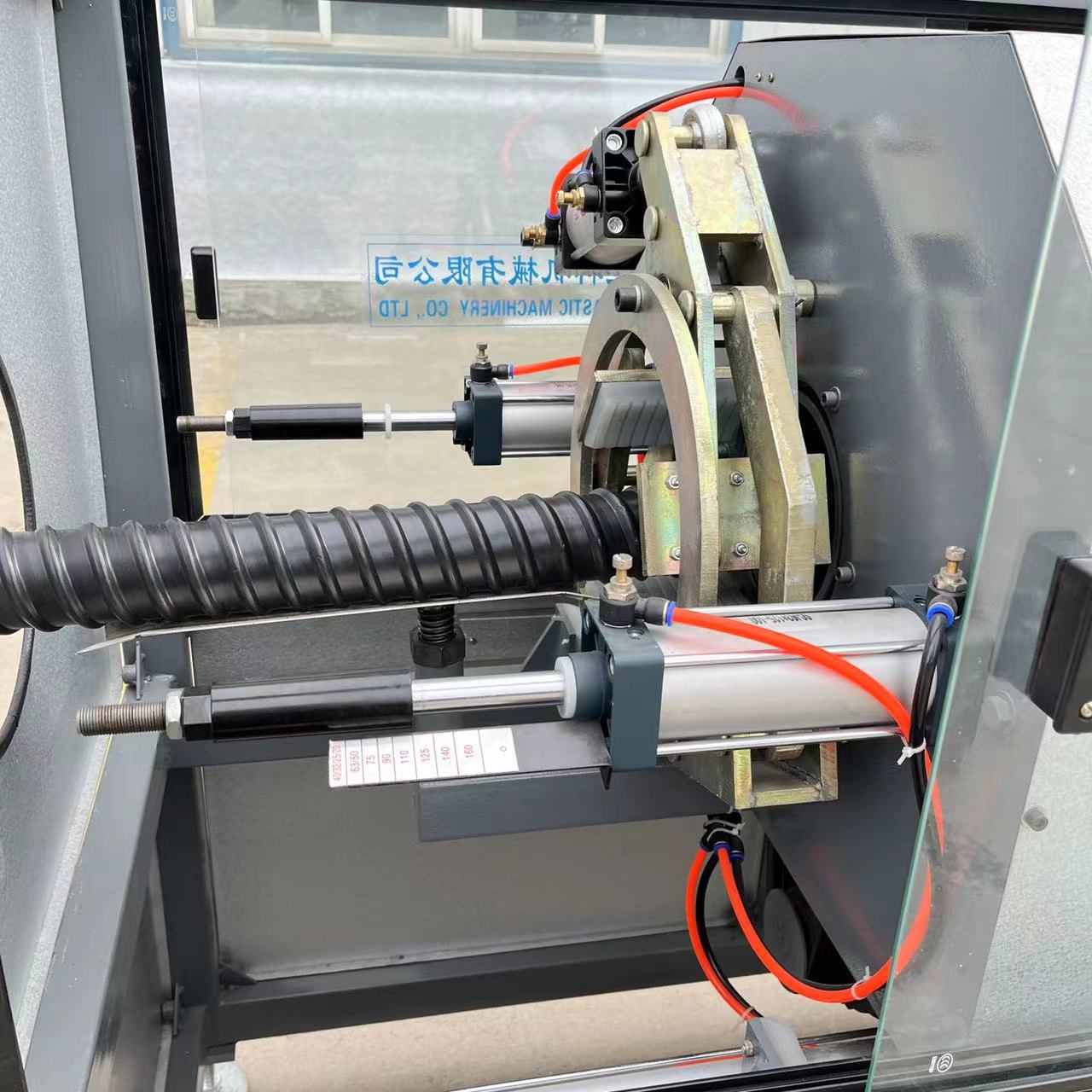

V. Hauling Machine 1 unit

Max distance apart 160mm

Effective hauling length 1200mm

Speed regulating mode frequency control (Fuji made in Japan)

Hauling power 3KW

Hauling form rubber block type

Early warning form light

VI. Winding Machine 1 unit

Winding form one-sided automatic winding

Driving type torque motor

Torque output 10N.M

Our shipment photo

Application

1)The cutting of the products do not produce chips, and cut sections smoothing products, thus saving products, raw materials, but also conducive to products with the corresponding pipes connector.

2)The cutting of the products at the line can be carried out simultaneously at any time, you can not cut the production line at any time of sampling.

3)Cutting the process smooth, no noise.

4)High automation, high cutting quantity and appearance is beautiful.