I. Parameters of products:

1. Suitable material: PC

2. Product specification: Approximate width: 2100mm

Range of thickness: 4-6-8-10mm

II. Detailed specification of the line:

Power: 380v/3p/50hz

Max Output of the extruder: 400kg/h

actual production output: 250kg/h

Total water consumption: 4m3 /h

Machine list:

Automatic uploading machine 1 set

SJ-120/35 single screw extruder with two hoppers one masterbatch dosing unit 1 set

SJ45-30 single screw extruder 1 set

Hydraulic pressure automatic screen changer 1 set

Gear pump 1 set

Grid plate die(as per sample provided) 1 set

Vacuum calibration set 1 set

Four pairs rollers Hauling-off machine 1 set

Oven(Infrared adjusting system) 1 set

Cooling off unit 1 set

The second hauling-off machine 1 set

two station protective film pay-off unit 1 set

Cutting machine 1 set

Stacker 1 set

Heat exchanger 1 set

Color mixer 1 set

Ⅲ. Detailed specification of the line:

1. Specification of the BSJ120/35 Extruder with two hoppers

Performance features:

Screw: Big output & L/D ratio. Two stage unique design effects, with low temperature plastication concept.

Barrel: barrel is made of special steel alloy, and is equipped with aluminum thermal foil with air cooling system.

Gearbox: gears are made of steel alloy with heat treatment and are finished with surface precision grinding. By using oil injection cooling system, it reduces noise when operating under high RPM and enhances the life span of gears.

Motor: AC motor, selected famous brand products. Controlled by ABB inventor.

Control system: Adopt selected high quality and famous brand products from Europe, and Japan manufactures. Machine works more stable and longer working-period.

With degassing system, the pressure is -0.09Mpa.

The extruder is equipped with two hoppers. One capacity 1000kg/h and the other is 500kg/h.

With Siemens touch screen.

| Model | BSJ-120/35 | |

| Extrude central height | 1100mm | |

| Max. output | PC | 400kg/h |

| High efficiency screw | ||

| Diameter | 120mm | |

| L/D | 35:1 | |

| Material | 38CrMoAlA | |

| Surface Treatment | Nitrided and Polished | |

| Barrel | ||

| Material | 38CrMoAlA | |

| Inner Surface treatment | Nitrided, ground | |

| Heating method | By ceramic | |

| Heating control zones | 7zones | |

| Cooling system | By blower fan 0.37kw per set | |

| Cooling zones | 7zones | |

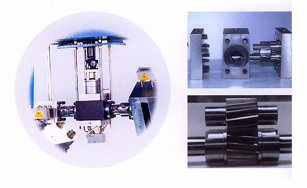

| Gearbox | ||

| Material of the house | QT200 | |

| Gear type | Helical gears | |

| Material of the gear | 20CrMnTi | |

| Heat treatment of the gear surface | Quenching | |

| Material of the axes bearings | 40Cr

Imported high quality bearing |

|

| Feeding block | ||

| Material | Q235 | |

| Method | Water circled cooling system | |

| Automatic feeder | ||

| Method | With master batch dosing unit | |

| Driving motor | ||

| Method | AC motor, 160KW | |

| Control system | AC inventor ABB brand | |

2.Specification of the BSJ45/30 Extruder one set

Performance features:

Screw: Big output & L/D ratio. Two stage unique design effects, with low temperature plastication concept.

Barrel: barrel is made of special steel alloy, and is equipped with aluminum thermal foil with air cooling system.

Gearbox: gears are made of steel alloy with heat treatment and are finished with surface precision grinding. By using oil injection cooling system, it reduces noise when operating under high RPM and enhances the life span of gears.

Motor: AC motor, selected famous brand products. Controlled by ABB Inverter.

Control system: Adopt selected high quality and famous brand products from Europe, and Japan manufactures. Machine works more stable and longer working-period.

| Model | BSJ-45/30 | |

| Max. output | UV | 32kg/h |

| High efficiency screw | ||

| Diameter | 45mm | |

| L/D | 30:1 | |

| Material | 38CrMoAlA | |

| Surface Treatment | Nitrided and Polished | |

| Screw rotation speed | 20~116r/min | |

| Barrel | ||

| Material | 38CrMoAlA | |

| Inner Surface treatment | Nitrided, ground | |

| Heating method | By ceramic | |

| Heating control zones | 4zones | |

| Heating power | 11KW | |

| Cooling system | By blower fan | |

| Cooling zones | 4zones | |

| Cooling power | 0.06KW | |

| Gearbox | ||

| Material of the house | QT200 | |

| Gear type | Helical gears | |

| Material of the gear | 20CrMnTi | |

| Heat treatment of the gear surface | Quenching | |

| Material of the axes bearings | 40Cr

Imported high quality bearing |

|

| Feeding block | ||

| Material | Q235 | |

| Method | Water circled cooling system | |

| Driving motor | ||

| Method | AC motor, 15KW | |

| Control system | AC frequency inverter ABB | |

| Overall dimension(L x W x H) | 1785mm x 340mm x 2070mm | |

| Weight | 900kg | |

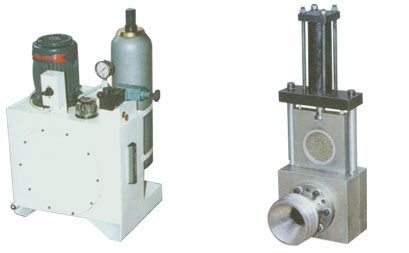

3. Hydraulic pressure automatic screen changer One set

Performance features:

The automatic screen changer can change the screen in a timely, prompt and reliable manner to ensure the constant and continual output of materials.

Type: Double-Section Quick Screen Changer.

Changing of screen within 2 seconds or below.

Keep the machine working and clean out the flotsam in time.

Hydraulic pressure driving

Screen changer mould: 90mm

With pressure sensor in the front of the screen changer.

4. Gear pump one set

150cc-1pcs gear pump

Performance features:

A gear pump is used to make sure that the pressure is stabilized by varying the speed of extruder through the help of computer according to the accurately measured pre-pump pressure, resulting in optimized material feeding process.

| Housing material | Chromium-nickel alloy | ||

| Gear material | Quench chromium steel | ||

| Bearing material | Graphite, NIAG, zirconium | ||

| Drive motor of Gear Pump | AC motor | r/min | 1440 |

| kw | 15 |

5. Grid plate die head One set

Performance features:

Performance features:

7. Four pairs rollers hauling off unit One set

Performance features:

To overcome the bigger resistant in the process of forming, in order to not destroy the hollow sheet, the sheet is fetched to match the four rubber steel rollers. When the down rubber drives, the up rubber rollers keep the vertical touch by the air pressure of cylinder.

| Technical data | Unit | Details |

| The diameter of per transporting roll | mm | 300 |

| Treatment method outside | Chromium plating | |

| Quantity of transporting rolls | pairs | 4 |

| Haul-off drive power | kw | 6 |

| Max Haul-off line speed | m/min | 4 |

| Slitting shears | set | 1 |

| Air vat | pieces | 8 |

| Material of the rubber roller | Silicon rubber |

8. Oven (Infrared adjusting system) two sets

Performance features:

The anneal unit is made up with a lot of quartz heating pipe which are average distributing the up and down side and adopt the far infrared spoke theory and make the sheet inner stress loose online in the light of infrared and make the sheet surface level off and thickness equality .The anneal unit is include automatic temperature adjustable and temperature show.

The heating oven is equipped with sheet support rollers.

| Technical data | Unit | Details |

| Heating power | KW | 30kw each set |

| Length | mm | 2000mm each set |

| Width | mm | 2300 |

| Height | mm | 1200 |

| Heating temperature range | 0~180 | |

| roller | pieces | 10 |

9.Cooling off unit one set

Performance features

The main function of this part is to cool off the PC sheet before it is cut next stage.

| Technical data | Unit | Details |

| Blower fans | pieces | 3*2 |

| Width | Mm | 2300 |

| Length | Mm | 1800 |

10. The second hauling-off machine One set

Performance features:

The second hauling off unit is consistent with two pairs of rubber roller as the same as the first hauling off , The down rubber roller is running by the acicular ring gear box with the direct connection to drive the chain wheel ,the upper rubber roller is controlled by the air pressure ,vertical tighten the hollow sheet and run . the motor adopt the frequency conversion to make the former hauling off has the same speed and draw the hollow sheet by anneal unit and cooling unit ,in order to make the hollow sheet enter the cutter machine .

| Technical data | Unit | Details |

| The number of hauling-off roller | pairs | 2 |

| Haul-off power | kw | 3 |

| Meter coder | piece | 1 |

| Air vat | pieces | 6 |

| Set length code | piece | 1 |

11. two station protective film pay-off unit one set

| Effective cutting width | 2100mm |

| Up and down unwinding diameter | 74mm |

12. Automatic heating blade cutter One set

Performance features:

The cutter is fixed on a frame with a wheel slippage, pushed by the cylinder, to make sure it moves with the profile. When get the signal from the photoelectric switch or the coder, the cutter will cut the profile automatically with a certain length.

Equipped with slitting unit.

| Technical data | Unit | Details |

| Cutting mode | ||

| Valid cutting range | mm | 2100 |

| Cutting power | KW | 0.75 |

| Length | mm | 2980 |

| Width | mm | 2900 |

| Height | mm | 1350 |

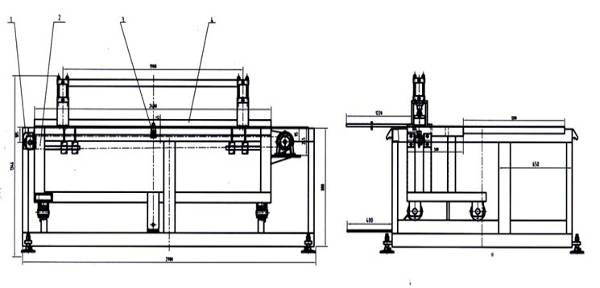

13. Stacker one set

Performance features:

The cut sheets are transported to the up-down platform, whish can adjust the height according to the quantity of the sheets. When the sheets reach a certain quantity, they’ll be put down by the stacker for packing.

| Technical data | Unit | Details |

| Production width | mm | 2100 |

| Length | mm | 2500 |

| Width | mm | 2300 |

| Height (can be adjusted ) | mm | 600~1200 |

SHEET EXTRUSION LINE SPARE PARTS

| NAME |

QTY |

|

| Die heating stick |

2 pcs |

|

| Fan blower |

1 pc |

|

| Heat relay |

(1 PCS for each specification) |

|

| Middle relay |

(1 PCS for each specification) |

|

| Temperature control meter |

1 pc |

|

| Electric valve for water |

1pc |

|

| Potentiometer |

2 pcs |

|

| Thermocouple |

4 pcs |

|

| Fuse core |

3 pcs |

|

| Electric heating plug |

2 pcs |

|

| Solid relay |

|

|

| Contactor |

1 pc |

|

| Current meter |

1 pc |

|

| Voltage meter |

1 pc |

|

|

|

||

for tools:

|

No. |

Spare Parts |

Qty |

|

1 |

monkey wrench 8’ |

1pcs |

|

2 |

monkey wrench 12’ |

1pcs |

|

3 |

inner hexagon spanner (1.5mm~10mm) |

1sets |

|

4 |

little shovel |

5pcs |

|

5 |

type screwdriver |

1pcs |

|

6 |

type screwdriver |

1pcs |

|

7 |

pliers |

1pcs |

|

8 |

Knife for cutting plastic pipe |

1pcs |

Post time: Oct-19-2023