SPECIFICATION OF THE SJSZ 80/156 PVC SHEET PRODUCTION LINE

I. Parameters of products:

1. Suitable material: PVC power

2. Product specification:

Sheet width: 1000mm

Sheet thickness: 0.25-1.5mm

II. Parameters of production line:

1. Powder: 380v/3p/50hz

2. Machine list:

• SJSZ 80/156 twin screw extruder one set

• T-die mould one set

• Three roller Calender one set

• Bracket and Haul-off machine one set

• double position winder one set

Ⅲ. Detailed specification of the line:

1. Specification of the SJSZ 80/156 Extruder

2.

Performance features:

• Screw: Big output & L/D ratio. Two stage unique design effects, with low temperature plastication concept.

• Barrel: barrel is made of special steel alloy, and is equipped with aluminum thermal foil with air cooling system.

• Gearbox: gears are made of steel alloy with heat treatment and are finished with surface precision grinding. By using oil injection cooling system, it reduces noise when operating under high RPM and enhances the life span of gears.

• Motor: AC motor, selected famous brand products. Controlled by ABB/DELTA Inverter.

• Control system: Adopt selected high quality and famous brand products from Europe, and Japan manufactures. Machine works more stable and longer working-period.

Automatic screw loader system

| Item | Description | Unit | remarks |

| 1 | Rated Charge Capacity | Kg/h | 500 |

| 2 | Max charge capacity | Kg/h | 500 |

| 3 | Motor Power | KW | 1.5 |

| 4 | Hopper volume | Kg | 120 |

| 5 | Spring diameter | mm | 36 |

| 6 | Storage volume | kg | 150 |

| Model | SJSZ-80/156 | ||

| Extrude central height | 1000mm | ||

| Max. output | 380kg/h | ||

| High efficiency screw | |||

| Screw quantity | 2 PCS | ||

| Diameter | 80mm,156mm | ||

| L/D | 22:1 | ||

| Effective length | 1820mm | ||

| Material | 38CrMoAlA | ||

| Surface Treatment | Nitrided and Polished | ||

| Screw rotation speed | 3.7~37r/min | ||

| Barrel | |||

| Material | 38CrMoAlA | ||

| Inner Surface treatment | Nitrided, ground | ||

| Heating method | By ceramic | ||

| Heating control zones | 4zones | ||

| Heating power | 38KW | ||

| Cooling system | By blower fan | ||

| Cooling zones | 4zones | ||

| Cooling power | 1KW | ||

| Gearbox | |||

| Material of the house | QT200 | ||

| Gear type | Helical gears | ||

| Material of the gear | 20CrMnTi | ||

| Heat treatment of the gear surface | Quenching | ||

| Material of the axes bearings | 40Cr Imported high quality bearing | ||

| Feeding block | |||

| Material | Q235 | ||

| Method | Water circled cooling system | ||

| Automatic feeder | |||

| Method | With vacuum suction method | ||

| Power | 1.1KW | ||

| Degassing system | |||

| Method | Vacuum degassing | ||

| Driving motor | |||

| Method | AC motor, 75KW | ||

| Control system | AC frequency converser | ||

| Overall dimension(L x W x H) | 5400mm x 850mm x 2500mm | ||

| Weight | 4500kg | ||

| Electrical control system | |||

| Motor:SIEMENS ,INVERTER :ABB/DELTA Contactor: Schneider /siemens Temperature controller meter : Omron or Delta

The control panel consists of power indicator, main engine on-off switch and emergency stop button. Low voltage electrical appliances are Siemens or Schneider products, and the main air switch is Delixi/CHINT products

|

|||

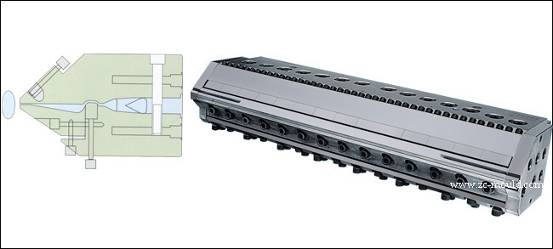

3. T-die mould One set

Performance features:

• Coated with chrome & polished

• Alloyed mould steel material

• Casting Alluminium heating band

| Width of product | mm | 1000 | |

| Sheet thickness | Min. | mm | 0.25 |

| Max. | mm | 1.5 | |

| Including | Die headDie painDie bushing

Heating band & support trolley |

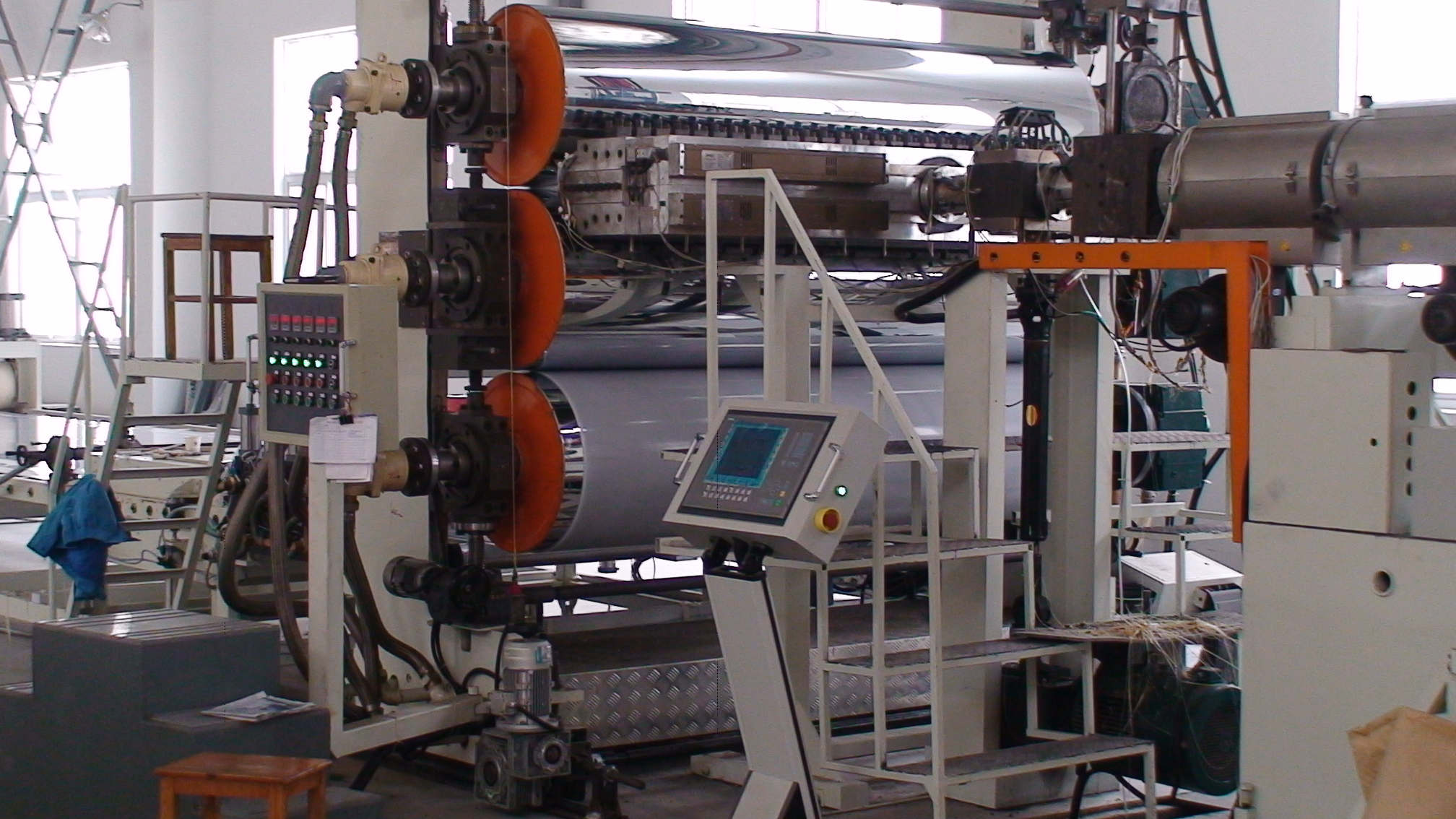

4. Calendar One set

Performance features:

• With emergency stop

• Adjusting method the roller space: Pneumatic adjusting

• Temp-regulating of roller: water-heating and cooling

• Low energy consumption

• Low noise design

| Inverter | ABB |

| Driving power | 2.2kw*3 |

| Transmission manner | Worm transmission |

| Width of roller | 1250mm |

| Diameter of roller | 400-450mm |

| Roughness of roller surface | R0.02 (Smooth of finish is above 12 grades) |

| Surface of roller | Plated with hard chromium |

| Depth | 0.1 ~ 0.12mm |

| Thickness of roller wall | 25-40mm |

| Dynamic balance | <5-10g |

| Roller throttles | 6-8 |

| Deviation of surface temperature | ≤2℃ |

| Charge manner | middle/down roller charging |

| Up-down roller adjusting | Electro motion, manual |

| Roller controlling | with high-strength heat exchange, three-roller individual water/oil temperature controller that ensures the convenience of adjusting. |

5. Bracket and Haul-off Machine One set

Performance features:

• A pair of rubber rollers haul off

• Speed adjustable control, the up and down rollers are synchronized via drive unit

• Low energy consumption

• Low noise design

| Dia. Of sloe-cooling roller | Mm | Ø70 | |

| Length of sloe-cooling roller | Mm | 1200 | |

| Dia. Of towing roller | Mm | Ø200 | |

| Towing linear velocity | Min. | m/min | 2 |

| Max. | m/min | 10 | |

| Towing motor | kw | 2.2 | |

| Width without edge | mm | 1200 |

6. double position winder One set

Post time: Aug-29-2023