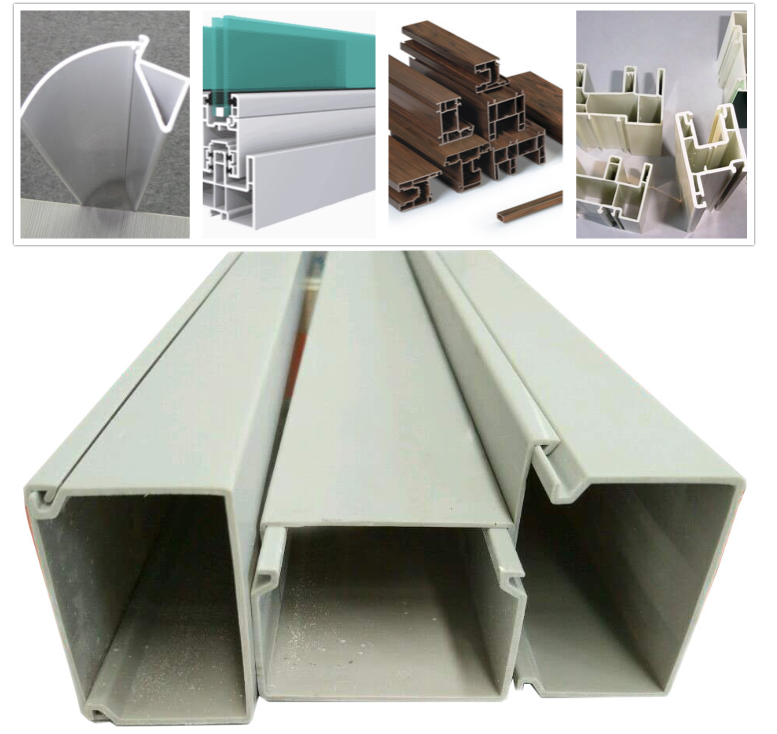

We call it PVC Cable Channel Making Machine/ PVC Wiring Duct Trunking Extrusion Production Line Description

PVC cable trunk production line is mainly used for making PVC Small profile like PVC Skirting profile,wall corner profile,PVC cable trunking profile with different section shape and height. the surface of PVC profile/panel can be treated by printing & coated with glossy oil, or by heat transfer printing, or by lamination, which can make good decoration effect for kitchen,toilet,balcony and so on.

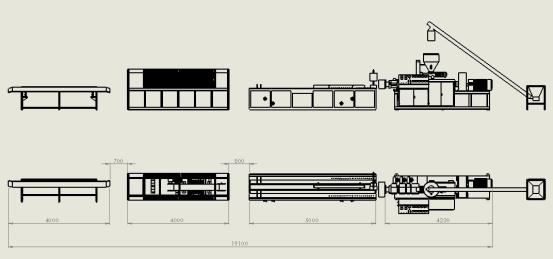

Extrusion line flowing as below:

SJZ Series Conical Twin Screw Extruder→Die mould→Vacuum Calibration Table→Haul-offs and Cutting Machine Unite→Stacker→Control cabinet

(Note: Other Auxiliary Machine,such as crusher,mixer,will be provided according to client's requirements)

(1) Automatic loader---1 set

(2) SJSZф55/110 conical twin screw extruder

| * adopts best screw and barrel ensure good plasticizing effect and longer lifetime

* adopts variable frequency motor, the heat radiating fan of motor is alone drived which can ensure good heat radiating effect even when motor at low rotating speed, it can effectively protect motor and improve lifetime * production speed is controlled by frequency inverter, easy adjusting, save electric consumption *automatic screw and barrel temperature control system, working automatically * all electric components adopt genuine world famous brand, such as: Schneider contactor, frequency inverter and so on * machine frame and based made of high strength square steel and steel plate, firmness and durable

Screw and barrel |

|||

| 1 | Screw Diameter | mm | ¢55/110 |

| 2 | Screw length | mm | 1440 |

| 3 | Screw quantity | pcs | 2 |

| 4 | Mesh type | Conical mesh | |

| 5 | Material of Screw and Barrel | / | Base material: 38CrMoAlA

Rapidwear surface with plasma alloy spray welding, thickness 1.5mm, more wearable and more correction resistance, increase lifetime |

| 6 | Counter rotating | rmp | 1-34.7 |

| 7 | Screw barrel | / | Special for PVC panel and PVC Profile |

| Screw and barrel temperature control system | |||

| 1 | Barrel Heating | / | Casting Aluminum Heater |

| 2 | Barrel Heating Power | KW | 24 |

| 3 | Barrel Cooling | / | Low noise fan blower cooling |

| 4 | Control | / | Intelligent Automatic |

| 5 | Temperature controller | Omron intelligent controller | |

| 6 | Screw core temperature adjusting | / | By circle conduction oil |

| Gearbox | |||

| 1 | Applicable standard | / | JB/T9050.1-1999 |

| 2 | Material of gear and shaft | / | Adopt high strength alloy, carburizing and quenching, grinding |

| 3 | Gear precision and hardness | / | 6grade, HRC 54-62 |

| 4 | Oil sealing | / | All sealing adopt good products |

| 5 | Screw Safeguard | / | Automatic screw displacement alarm |

| 6 | Cooling | / | By water |

| Dosing feeding device | |||

| 1 | Feeding motor power | KW | 1.1 |

| 2 | Feed adjusting | / | By holip frequency inverter |

| 3 | Can be adjusted separately or synchronized adjusting with extrusion. | ||

| Power system and electric control | |||

| 1 | Main Motor Power | KW | 22(AC motor) |

| 2 | Speed adjusting mode | / | Variable frequency converter |

| 3 | Frequency inverter | / | holip inverter |

| 4 | AC contactor | / | Schneider |

| 5 | Air switch | / | Schneider |

| 6 | Melt pressure meter | / | YES |

| Vacuum exhausting system | |||

| 1 | Vacuum pump | / | Hydroseal vacuum pump |

| 2 | Vacuum pump power | KW | 1.5KW |

| Machine frame | |||

| 1 | Material | Made of steel square tube | |

| 2 | Deck plate | / | High strength thick steel plate |

| 3 | Extruder axis height | mm | 1000 |

Vacuum calibration and cooling table

| Item | Description | Unit | remarks |

| Features:

Compact structure, beautiful appearance, easy to operation and maintain. Adopt superior quality vacuum & water pump, electric components to make sure durable continuous working |

|||

| 1 | Power/number of vacuum pump | KW | 4kw×2set |

| 2 | Max vacuum pump degree | Mpa | -0.08Mpa |

| 3 | Power/number of water pump | KW | 3kw×1set |

| 4 | Move forward and backward method | / | Motor driven |

| 5 | Cooling water circulation | / | Automatic |

| 6 | Axis let and height adjuting | / | Manual thread adjustment |

| 7 | Axis height adjusting | / | Manual thread adjustment |

| 8 | Length of calibrator | mm | 4000mm |

(4) Tractor

| Item | Description | Unit | remarks |

| Features:

Frequency conversion speed adjusting, pneumatic clamp and release |

|||

| 1 | Width and effective length of pedrail | mm | 260mm/1200mm |

| 2 | Speed adjust mode | / | Frequency conversion |

| 3 | Max. traction force | N | 15000 |

| 4 | Traction speed | m/min | 0.5--5 |

| 5 | Traction motor power | KW | 2.2 |

| 6 | Material of traction block | / | Rubber |

| 7 | Central height | mm | 1000 |

(5) Cutter

| Item | Description | Unit | remarks |

| Features:Adopts famous electromagnetism valve, dustproof electric cabinet to keep electric system away from cutting dust and make machine working reliable and no-break. | |||

| 1 | Power | KW | 1.5 |

| 2 | Saw blade material | mm | Superior quality alloy steel |

| 3 | Cutting Mode | / | Pre-set length, cut in fixed-length automatically with meter counting |

| 4 | Central height | mm | 1000 |

(6) Stacker

| 1 | length | 6m |

| 2 | Discharge mode | pneumatic drive |

| 3 | Splint material | stainless steel |

| 4 | Structure | Disassemble |

Electrical Configuration

1) Main motor frequency controller: ABB

2) Temperature controller: OMRON/RKC

3) AC contactor: Siemens

4) Thermal overload relay: Siemens

5) Breaker: CHINT or according to customer requirement

Full Service

1) Pre-sale service:

To provide market research information and consultation

To help customers make project planning and systematic analysis

To maximize customer’s satisfaction

To achieve the mutual benefits of our customers and our company

2) After-sale service:

To install products and test products for customers

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories

To provide technical direction according to customers’ requirements

To provide technical training for clients’ employees

Post time: Oct-09-2023