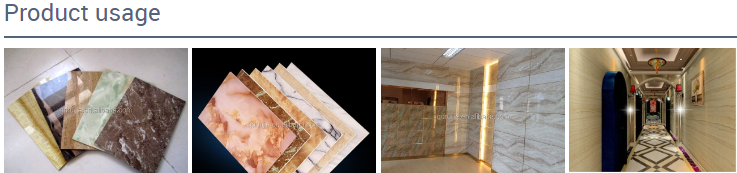

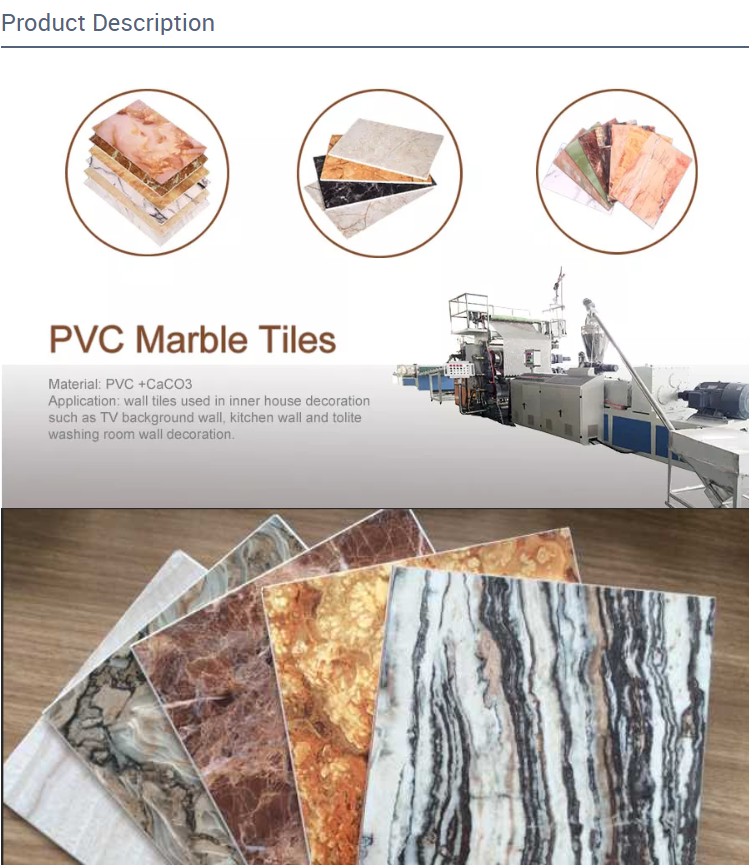

imitation marble sheet which have marble, carpet, stones, natural scenery, stereo design on the surface. And the board is popular in the hospital, school, office buildings, shopping malls,supermarkets, transportation and other public places.

Processing flow of PVC Artificial marble stone sheet production line:

SHR500/1000Mixer→Auto loader→SJSZ80/156 conical twin screw extruder →Mould→ Three calender(online laminating) →Edge cutter→Hual off machine→ Transversal cutter → Conveyor→UV treatment →Final PVC marble sheet

Machine parameter:

1.Material used: PVC powder, calcium cabonate powder and additives

2.Output: 400-600Kg/h

3. Products width: 1220mm

4. Products Thickness: 2-6mm

5. Auto stacker

7. Line speed: 0.2-3m/min

8. Please send inquiry to us for more information.

PVC artificial marble sheet production line

Sheet size: (1220mm*2240mm)

Thickness 2-6mm

Machines list

| No. | Machine name | Weight (kg) | Quantity |

| 1 | Automatic feeding machine | 150 | 1 |

| 2 | SJSZ80/156 Double conical twin screw extruder | 5000 | 1 |

| 3 | PVC marble sheet mould | 1500 | 1 |

| 4 | Three/Four-roller calendaring machine | 6000 | 1 |

| 5 | Roller temperature controlling device | 500 | 1 |

| 6 | Cooling shaft | 300 | 1 |

| 7 | Two-roller haul-off machine | 400 | 1 |

| 8 | Dust free sheet shearing machine | 400 | 1 |

| 9 | Automatic mechanical arm | 300 | 1 |

Extruder Advantages

1. Double screws feeder.

2. ABB/DELTA inverter, Siemens motors, Siemens contactors.

3. PLC control system is optional.

4. High quality gearbox, screws and barrel .

5. Automatic feeder.

6. Please send inquiry to us for more information.

| Aftersell service |

| 1).We will provide the Feasibility Analysis Report for the wood-plastic project. 2)We will provide the model selection and technical parameter for wood-plastic machinery. 3).We will provide the design for the plant and electric power accounting for the facilities. 4).We will provide the design for wood-plastic formula according to the product requirements. 5).We will provide the technology of wood-plastic product surface treatment 6).We will provide technique training for operator. 7).We will provide solution for the practical problem during the production. 8).We will install and test the machine for free. 9).We will provide turnkey project to customers |

Post time: Oct-09-2023