PVC double pipe extrusion production line

The process flow of UPVC pipe production line as following:

Mixing → Extruding & Molding→ Vacuum Calibration and Cooling → Printer→ Hauling off→ Cutting →belling (optional) → final PVC pipe

A. Necessary Machines for UPVC Pipe Extrusion Line

- 1 set of Conical Double-Screw Extruder – SJSZ65/132

- 1 set of material autoloader

- 1 set Double cavity Mould (according customer size and thickness )

- 1 set of Vacuum Calibration Tank - ZK-63

- 1 set of Hauling and cutter Machine – QY-63

- 1 set of stacker

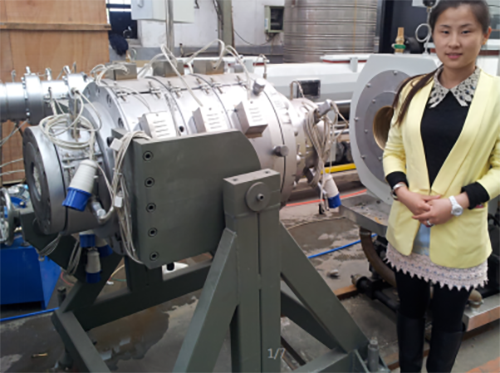

1. SJSZ65/132 Conical Double Screw Extruder

2. Autoloader

3. Double cavity Mould

Size and thickness according customers request .

4.Vacuum Calibration and cooling water Tank

| Item | Description | ZK-63 |

| *with automatic water temperature controller, easy for operation*adopt intelligent vacuum pump with malfunction alarm, effectively protect pump and improve its life time | ||

| 1 | Length | 4000mm |

| 2 | Material | stainless steel |

| 3 | Cooling Type | Spray-pouring cooling |

| 4 | Water Pump | 2.2KW×2set |

| 5 | Vacuum Pump | 4KW×2set |

| 6 | Level Control | Ball valve automatically control |

| 7 | Motion Range of To and Fro | ±600mm,Motor drive,power: 0.75kw |

| 8 | Up-down Adjusting Range | ±120mm |

| 9 | Left-right Adjusting Range | ±50mm |

| 10 | Axes line height | 1000mm |

| 11 | Element of Electric System | From Schneider |

| 12 | Vacuum pump | Famous brand |

| 13 | Figure Dimension | 4000×800×1400 |

5. All in one haul off and cutter Machine

| Item | Description | QY-63 | |

| Hauling off machine* speed is freely regulated by frequency inverter, synchronized with extruder speed* adopt famous Airtac air cylinder, steady performance, reduce maintain cost | |||

| 1 | Available Grasping Length | 800mm | |

| 2 | Control Mode | Hauling speed is Controlled by Main Machine synchronously | |

| 3 | Speed Adjusting Mode | frequency conversion adjustable | |

| 4 | Clamping Mode | Pneumatically Drive | |

| 5 | Hauling Mode | Up-down Hauling by Special Rubber Block | |

| 6 | Transmission Mode | Traction | |

| 7 | Hauling Motor Power | 1.5kw×2set | |

| 8 | Pressure of compressed air supply | ≥0.6 | |

| 9 | Axes Height | 1000mm | |

| Cutting Machine* PLC control, automatic cutting and counting, easy for production operation* adopt famous Airtac air cylinder, steady performance, reduce maintain cost | |||

| 1 | Cutting Pipe-wall thickness | < 40mm | |

| 2 | Cutting motor power | 1.5KW×2set | |

| 3 | Material of Cutting Saw | Alloy steel | |

| 4 | Clamping Mode | Pneumatically | |

| 5 | Valve of Pneumatic system | From AIR TAC | |

7. Stacker

Spare part list (free):

| No. | Name | Qty. | Used for |

| 1 | Big spanner | 1 set | extruder |

| 2 | Rubber block | 10pcs. | Haul-off |

| 3 | Seal | 10m | Vacuum tank and spray cooling tank |

| 4 | Sprayer | 15pcs | |

| 5 | Thermocouple | 5 sets | Extruder |

| 6 | Contactor | 2pcs | Electrical cabinet |

| 7 | Button and switch | 2pcs | |

| 8 | Relay | 2pcs |

Thanks for cooperation! Sincerely Hope to work with you in near future!

Post time: Sep-14-2023