ASA+ PVC co-extrusion profile extrusion line

it is very popular in INDIAN market now .it is use two extruder co-extrusion making , SJSZф65/132 conical twin screw extruder+SJ45single screw extruder.

1. Uses:

pvc door frame profiles

2. Capacity: about 200kg/h

3. Equipment components:

(1) Autoloader

(2) SJSZф65/132 conical twin screw extruder+SJ45single screw extruder

Mould according drawing .

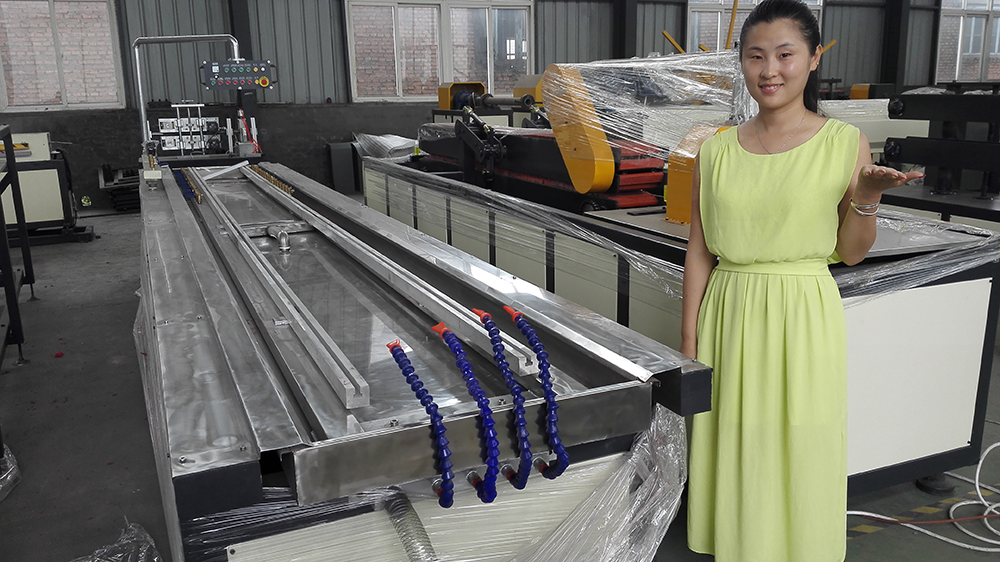

(3) 10m vacuum calibration and cooling table

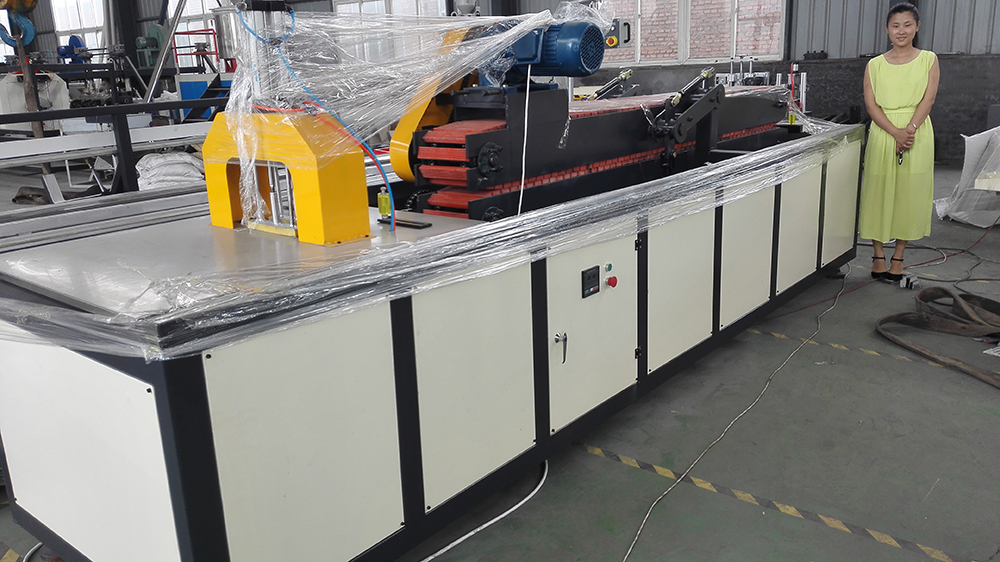

(4) All-in-one hauling & cutting machine

(5) Stacker

4. Parameter of components

(1) Autoloader

| Item | Description | Unit | remarks |

| 1 | Transport tube diameter | mm | 102 |

| 2 | Charging motor power | KW | 1.5 |

| 2 | Push material motor power | KW | 0.75 |

| 4 | Charge capacity | Kg/h | 600 |

| 5 | Storage volume | kg | 150 |

| 6 | Material of storage hopper and tube | / | Stainless steel |

(2) SJSZф65/132 conical twin screw extruder

| * adopts best screw and barrel ensure good plasticizing effect and longer lifetime

* adopts variable frequency motor, the heat radiating fan of motor is alone drived which can ensure good heat radiating effect even when motor at low rotating speed, it can effectively protect motor and improve lifetime * production speed is controlled by frequency inverter, easy adjusting, save electric consumption *automatic screw and barrel temperature control system, working automatically * all electric components adopt genuine world famous brand, such as: Siemens or Schneider contactor, ABB or FUJI frequency inverter and so on * machine frame and based made of high strength square steel and steel plate, firmness and durable ﹡Self protective system: current of motor overload automatic stop protection screw displacement automatic stop protection Lubrication oil starvation automatic alarm device |

|||

| Screw and barrel | |||

| 1 | Screw Diameter | mm | ¢65/132 |

| 2 | Screw length | mm | 1440 |

| 3 | Screw quantity | pcs | 2 |

| 4 | Mesh type | / | Conical mesh |

| 5 | Material of Screw and Barrel | / | 38CrMoAlA Nitrogen Treatment |

| 6 | Counter rotating | rmp | 1-37 |

| 7 | Screw barrel | / | Special for PVC WPC profile |

| Screw and barrel temperature control system | |||

| 1 | Barrel Heating | / | Casting Aluminum Heater |

| 2 | Barrel Heating Power | KW | 24 |

| 3 | Barrel Cooling | / | Low noise fan blower cooling |

| 4 | Control | / | Intelligent Automatic |

| 5 | Temperature controller | Omron intelligent controller | |

| Gearbox | |||

| 1 | Applicable standard | / | JB/T9050.1-1999 |

| 2 | Material of gear and shaft | / | Adopt high strength alloy, carburizing and quenching, grinding |

| 3 | Gear precision and hardness | / | 6grade, HRC 54-62 |

| 4 | Oil sealing | / | All sealing adopt good products |

| 5 | Screw Safeguard | / | Automatic screw displacement alarm |

| 6 | Cooling | / | By water |

| Dosing feeding device | |||

| 1 | Feeding type | / | Screw dosing feeding |

| 2 | Feeding motor power | KW | 1.1 |

| 3 | Feed adjusting | / | By ABB/DELTA frequency inverter |

| 4 | Can be adjusted separately or synchronized adjusting with extrusion. | ||

| Power system and electric control | |||

| 1 | Main Motor Power | KW | 37(AC motor) |

| 2 | Speed adjusting mode | / | By ABB/DELTA frequency inverter |

| Control system | |||

| a) Inverter: ABB/ DELTAb) Temperature controller:DELTA/OMRON

c) Contactor and main electric components: Schneider/siemens |

|||

| Vacuum exhausting system | |||

| 1 | Vacuum pump | / | Hydroseal vacuum pump |

| 2 | Vacuum pump power | KW | 1.5KW |

| Machine frame | |||

| 1 | Material | Made of steel square tube | |

| 2 | Deck plate | / | High strength thick steel plate |

| 3 | Extruder axis height | mm | 1000 |

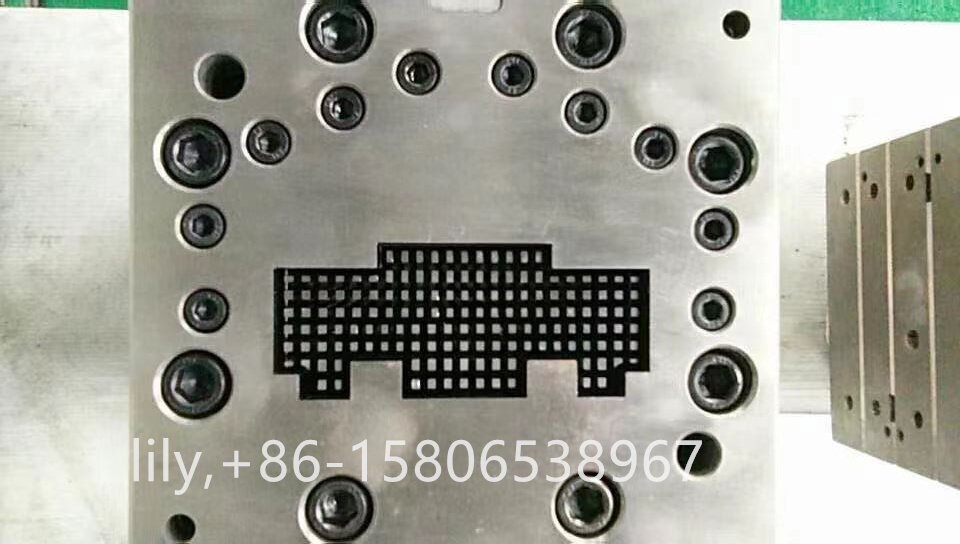

Mould picture

(3) DF10000 vacuum calibration and cooling platform

(4) All-in-one hauling-off and cutting machine

| Item | Description | Unit | remarks | |

|

Hauling-off machine *pneumatic clamping and releasing *variable frequency conversion speed adjusting * adopts superior quality wearable rubber block |

||||

| 1 | Haul off structure | 2-pedrails haul off, Individual drive | ||

| 2 | Width and of pedrails | mm | 300mm

|

|

| 3 | Haul off speed | m/min | 0.5--3 | |

| 4 | Speed adjusting model | / | Variable frequency conversion | |

| 5 | Max. traction force | N | 35000 | |

| 6 | Traction motor power | KW | 3 | |

| 7 | Upper Pedrail on off method | / | Pneumatic drive | |

| 8 | Central height | mm | 1000 | |

| Cuttingmachine * control, automatic cutting, meter counting * pneumatic clamping and automatic cutting return * Powerful saw blade cutting with clean cutting sections |

||||

| Item | Description | Unit | remarks | |

| 1 | Structure of cutter | / | Up lift cutting, automatic cutting, automatic return | |

| 2 | Max cutting thickness | mm | 100mm | |

| 3 | Cutter Power | KW | 2.2 | |

| 4 | Cutting blade | Round plate type | ||

| 5 | Blade diameter | mm | Φ450 | |

| 6 | Cutting clamping | Pneumatic clamping | ||

| 7 | Cutting return | Pneumatic return | ||

| 8 | Dust collection | / | By air blower | |

| 9 | Central height | mm | 1000 | |

| 10 | Dimension | mm | 5500×1100×1600 | |

(5) Stacker

|

||

| 1 | length | 6m |

| 2 | Tilting mode | pneumatic drive |

| 3 | Material of overturn board | stainless steel |

| 4 | Cutting and tilting sensor | Position switch or optoelectronic switch |

| 5 | Dimension | 6000×800×1200 mm |

ASA SJ45X30 single screw extruder

| Screw diameter | 45 mm |

| L/D | 30:1 |

| Motor power | 11kw |

| Rotating speed of screw | 80 r/min |

| Heating power | 10kw |

| Extrusion capacity | 50kg/h |

| Center height | 1000 mm |

| Weight | 700kg |

| Dimension | 2000 x 1200 x 1500mm |

| Extruder speed adjusting way | Frequency conversion |

| Barrel temperature adjusting way | Heating: cast aluminum heater

Cooling: 3 sections by air |

| Material of screw and barrel | 38CrMoAlA Azotizing on surface 0.4~0.7mm

Rigidity: above 700 HV |

| Drive way | Hard tooth gearbox |

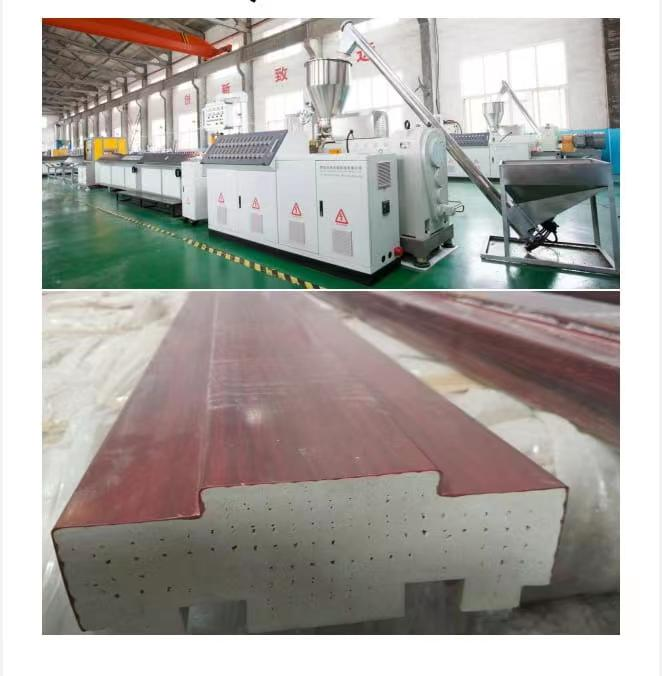

We done Sample photo :

Post time: Sep-14-2023