HDPE plastic pipe extrusion line machine

ASA+ PVC co-extrusion profile extrusion line

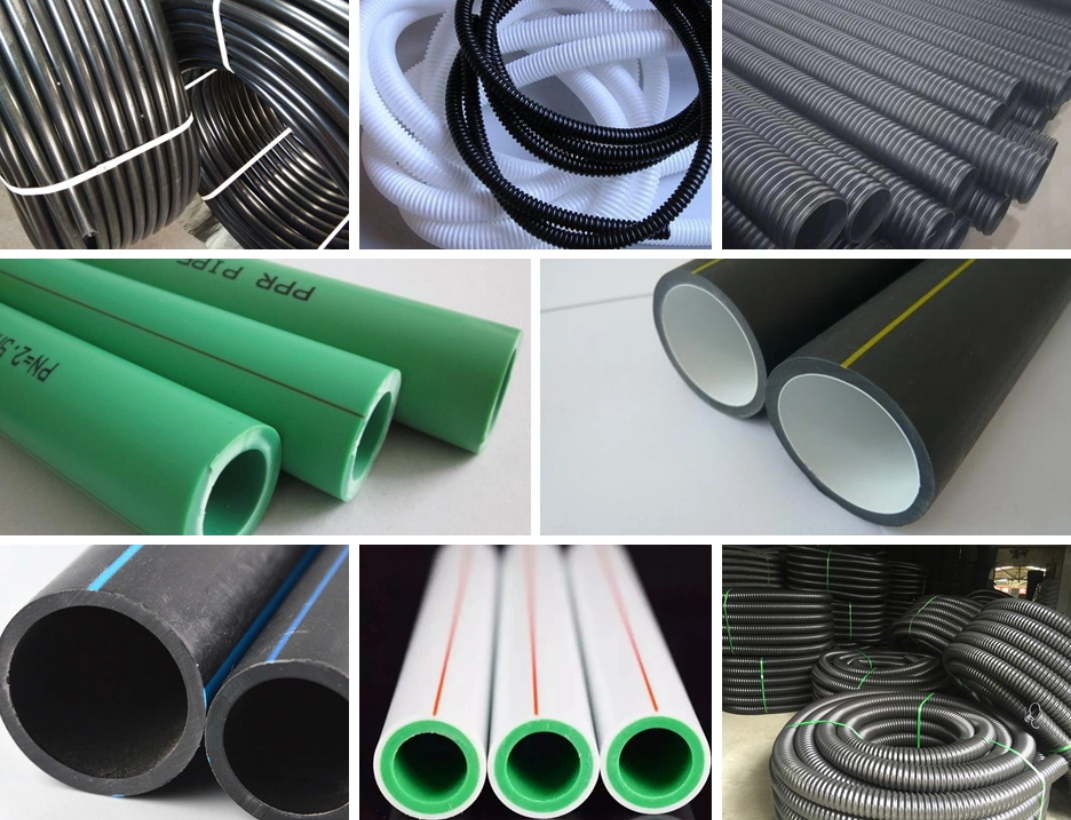

1. HDPE plastic pipe extrusion machine is mainly used for producing agricultural irrigation pipes, drainage pipes, gas pipes, water supplying pipes , cable conduit pipes etc.

>>The pipe has some excellent features such as heating resistant, aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant, etc. our extrusion line is designed with high efficiency extruder and equipped with reducer which is high speed and low noise, Gravimetric dosing unit and ultrasonic thickness indicator can be assembled according to customer's demand to ascend the precise of the pipes .

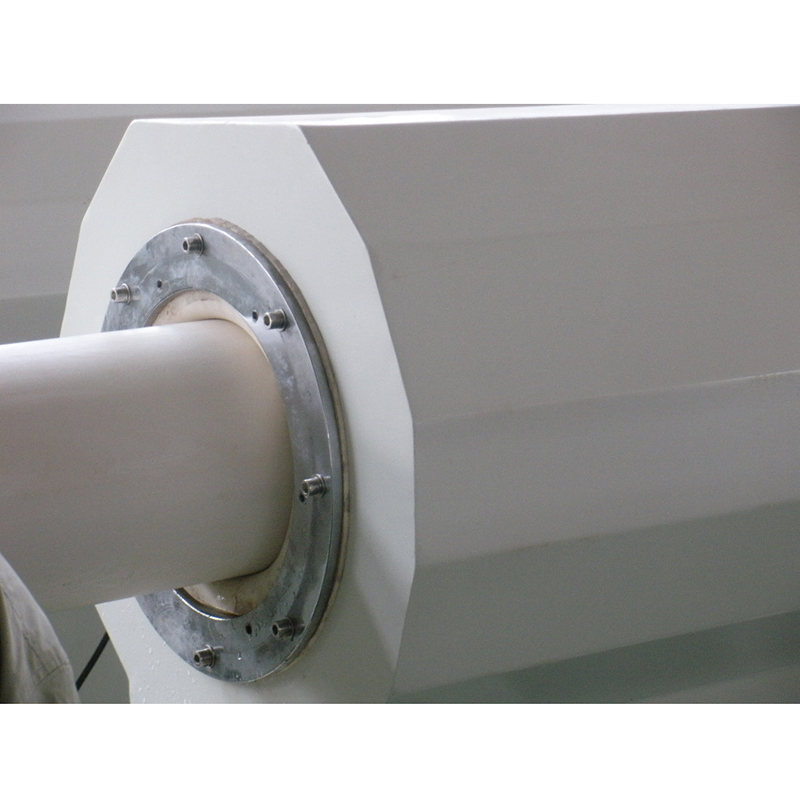

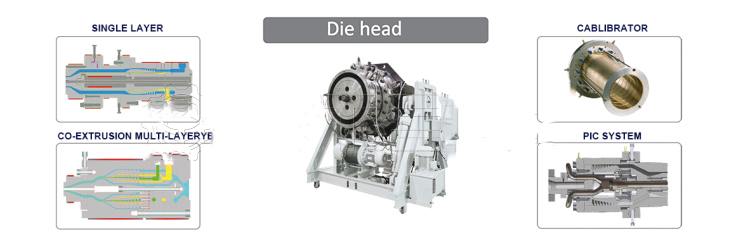

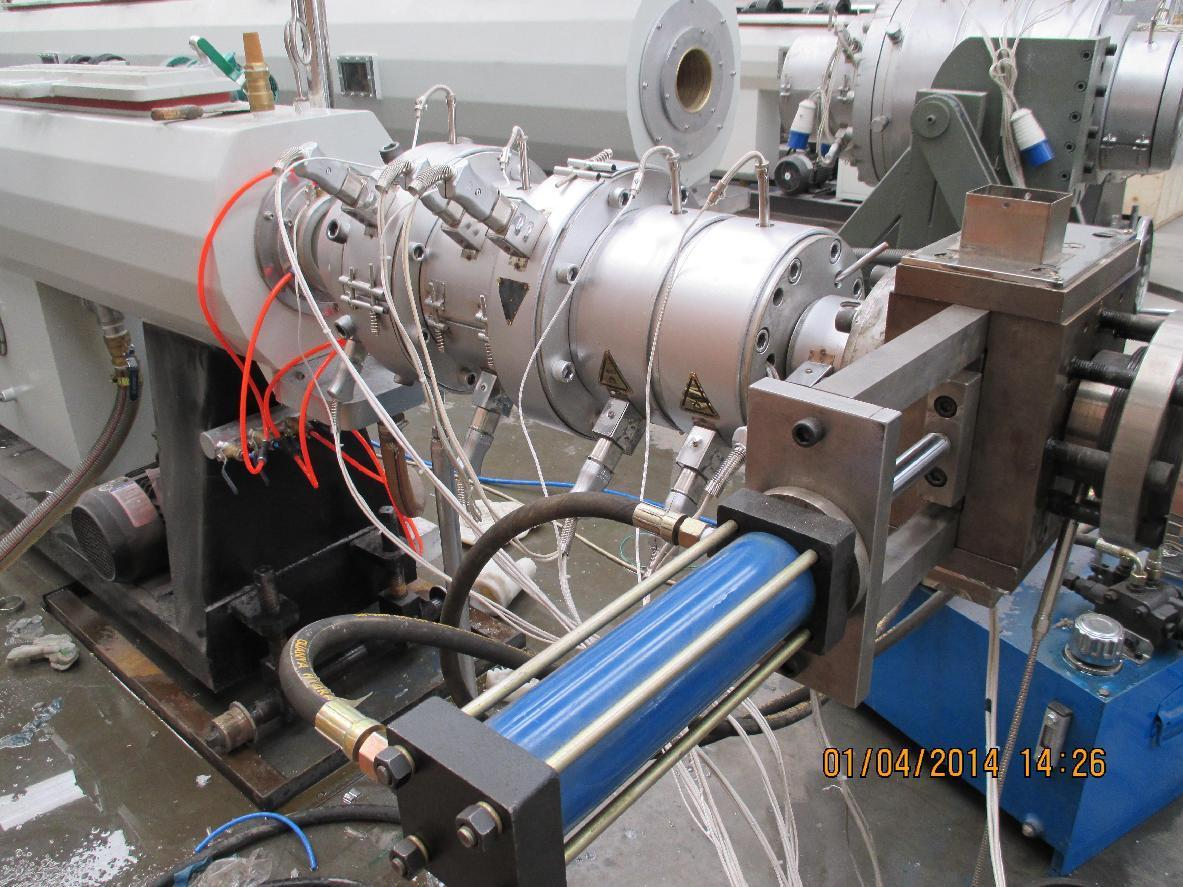

2.PE pipe die head

HDPE plastic pipe extrusion line machine

Detail Technical Parameters of Each Above machines

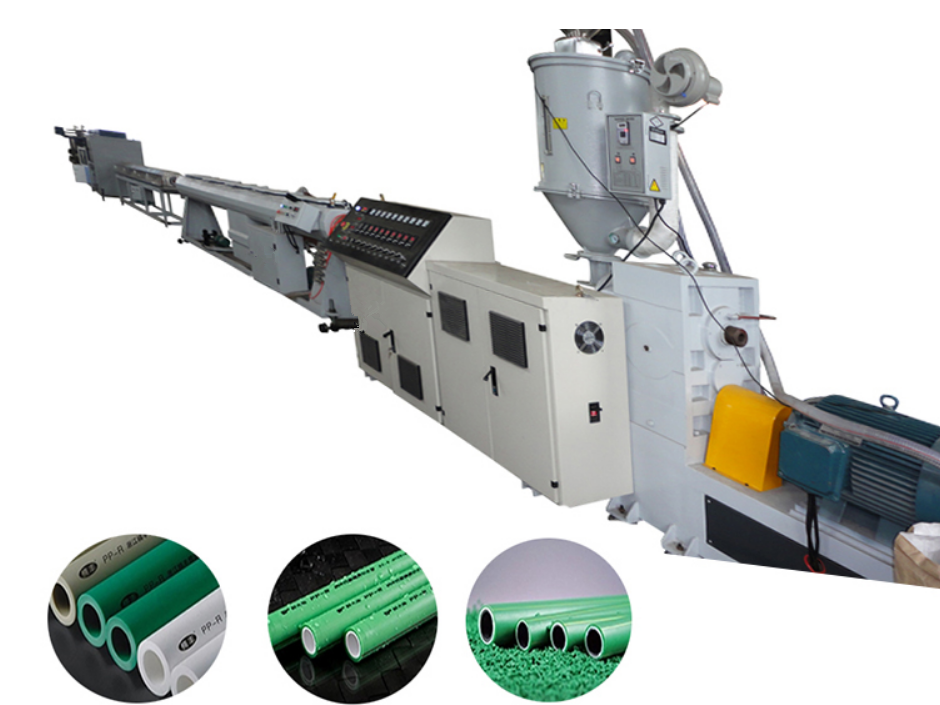

The process flow of PE pipe production line as following:

Material feeder → Hopper dryer→ Extruding & Molding→ Vacuum Calibration and Cooling → Printer→ Hauling off→ Cutting →final PE pipe

Automatic material loader

|

NO |

Description |

Unit |

ZJ-200 |

| ﹡ working principle: vacuum suction﹡ automatic start and stop the loading action | |||

| Function: charge PE granules into hopper dryer | |||

| 1 | Static pressure max. | Pa | 9800 |

| 2 | Motor power | KW | 1.1 |

| 3 | Electric power supply required | As request | |

| 4 | capacity | 5m | 200kg/h |

| 10m | 150kg/h | ||

| 5 | Suction hopper volume | L | 10 |

2.1 set of Hopper dryer

| NO | Description | Unit | Remarks |

| 1 | Barrel diameter | mm | 600 |

| 2 | Material | / | Stainless steel |

| 3 | Sight glass window | / | yes |

| 4 | Down slide door plate | / | yes |

| 5 | Heating power | Kw | 9 |

| 6 | Power of air blower | kw | 0.55 |

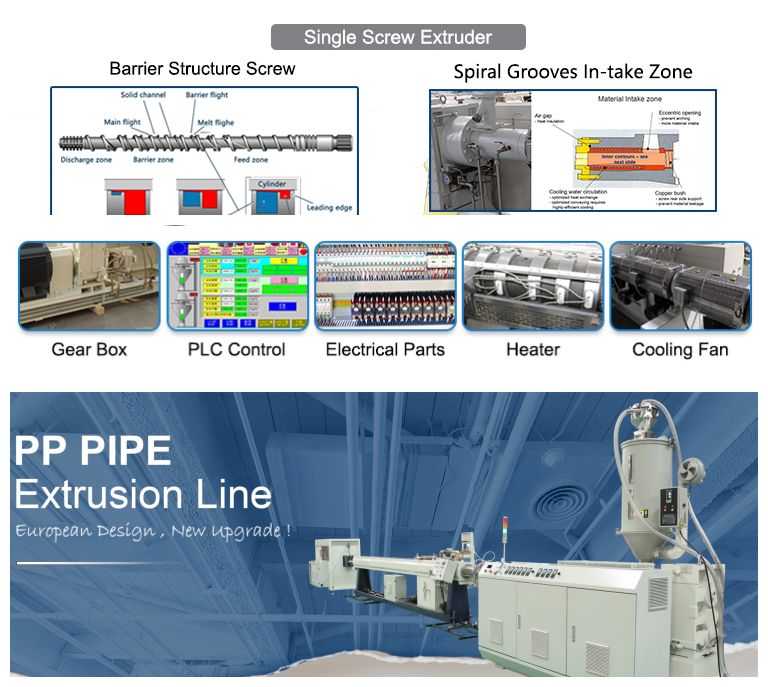

3. 1 set of SJ65/33 or SJ75/30 single screw extruder

| ﹡Screw、barrel design and manufacturing absorb European advanced technology(from big famous screw barrel company)﹡Screw and barrel material:38CrMoAlA,nitriding treated

﹡Exclusive screw for PE material make sure good plasticizing effect ﹡adopt original famous electric components with high steady running quality . ﹡Gearbox: high torque, low noise, hard gear tooth face dedicated extruder gear box ﹡Self protective system: Over current protective of motor Over pressure protective of screw |

||

|

General description |

Main electric elements | Frequency inverter:ABB /deltaAC Contactor: Schneider or siemens

Air-break switch: Schneider Temperature controller: omron/delta Voltage meter and current meter: DELIXI |

| Output | Around 200kg/h | |

| Connect type of extruder and mould | Bolt connection | |

| Advantages | Main parts adopt top-rank brandStrict real time quality control | |

| Screw | Diameter(mm) | 65mm |

| L/D | 33/1 | |

| Material | 38CrMoAlA, Nitrogen treated | |

| Heating | Casting aluminum heater with stainless steel outer cover | |

| Heating segments | 5 zone | |

| Heating power | 20kw | |

| Barrel | Barrel type | With feeding groove; Water cooling inlet orifice |

| Cooling | Cooling by blower,temperature control accuracy: ±1℃ | |

| Cooling segment | 5 segments | |

| Material | 38CrMoAlA, Nitrogen treated | |

| Drive andTransmission system | Main motor power(KW) | 55kw famous brand in china |

| Speed adjusting mode of main motor | Variable frequency conversion | |

| Rotating speed of main motor (r/min) | 1500r/min | |

| Gear box | Hard gear tooth face Low noise designShaft: NSK of Japan Material of gear: 20CrMnTi |

|

4. 1 set of mark line co-extruder SJ25/25

|

Item |

Description |

Unit |

SJ25/25 |

|

1 |

Diameter of the Screw |

mm |

25 |

|

2 |

Ratio of length to diameter |

|

25:1 |

|

3 |

Output |

Kg/h |

1.5-10 |

|

4 |

Rotation Speed of the Screw |

rev/min |

5-50 |

|

5 |

Material of the Screw barrel and the Screws |

|

38CrMoAlA |

|

6 |

Gear box |

|

Hard tooth face , low noise design |

|

7 |

Heating Capacity of the Screw barrel |

KW |

6 |

|

8 |

Heating areas of the barrel |

|

2 |

|

9 |

Main Motor Power |

Kw |

0.75 |

|

10 |

Speed Adjusting Mode |

|

frequency conversion |

|

11 |

Cooling for barrel |

|

Air flow cooling, 2- areas |

|

12 |

Height of the Screw Axes |

mm |

1000 |

|

13 |

Temperature controller |

|

Brand: omron, Japan |

|

14 |

Frequency Converter |

|

Brand: ABB, Japan |

|

15 |

Figure dimension |

mm |

1450×450×1500 |

|

16 |

Weight |

kg |

250 |

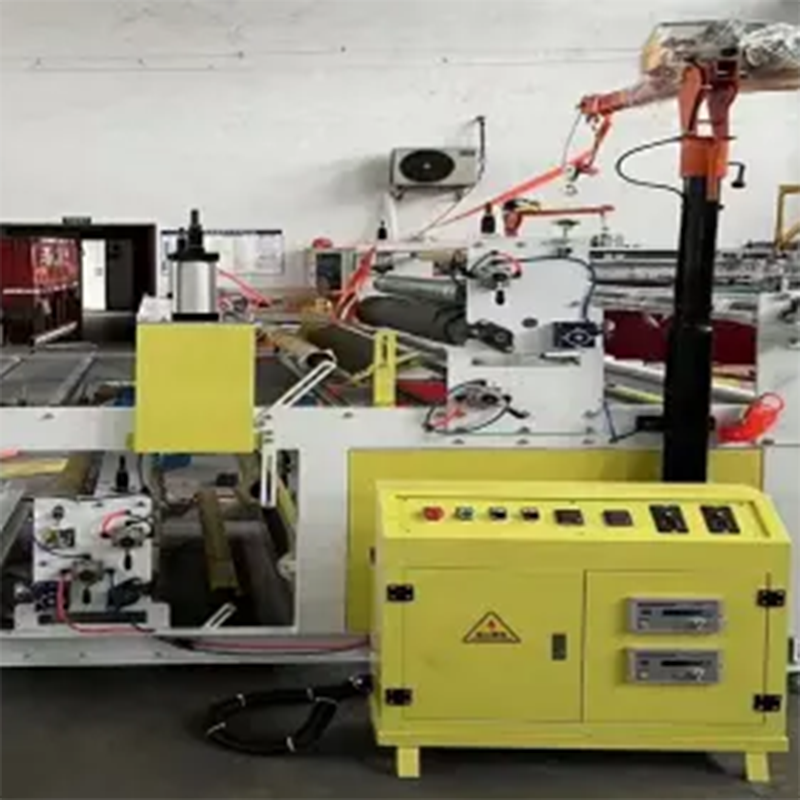

Shipment photos: