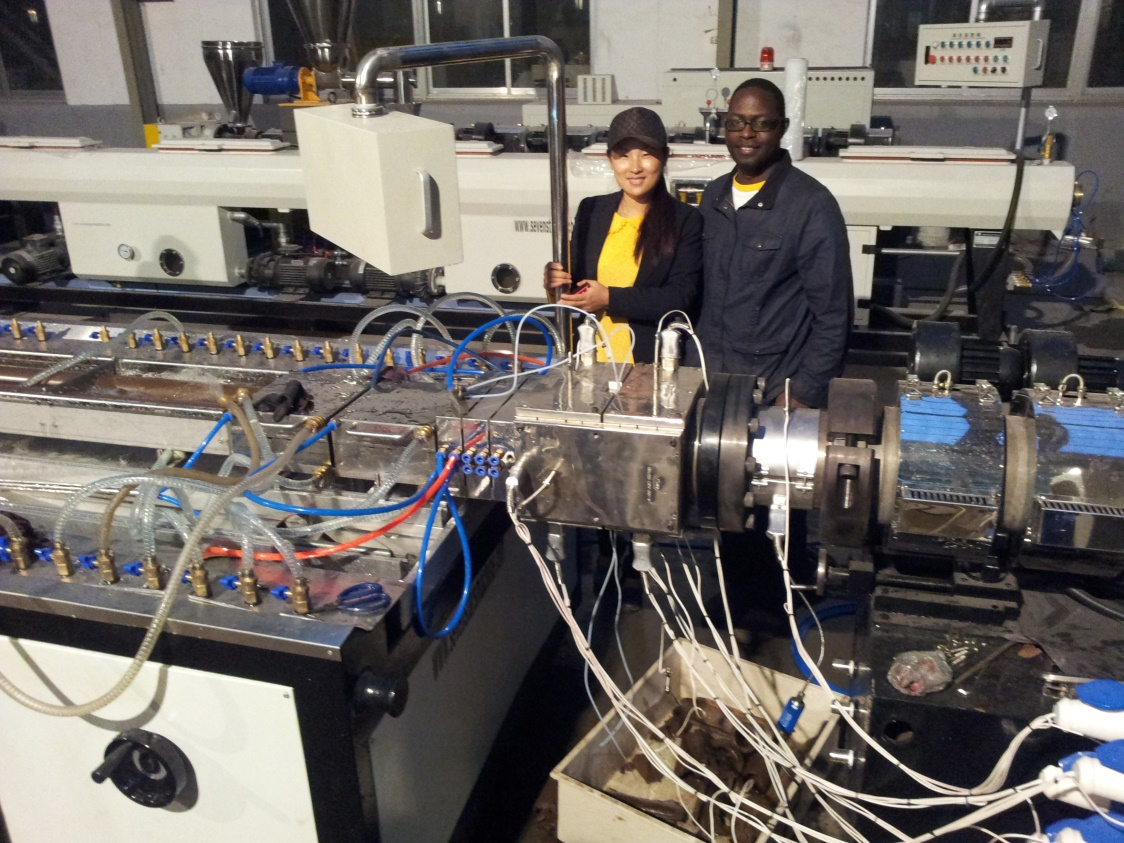

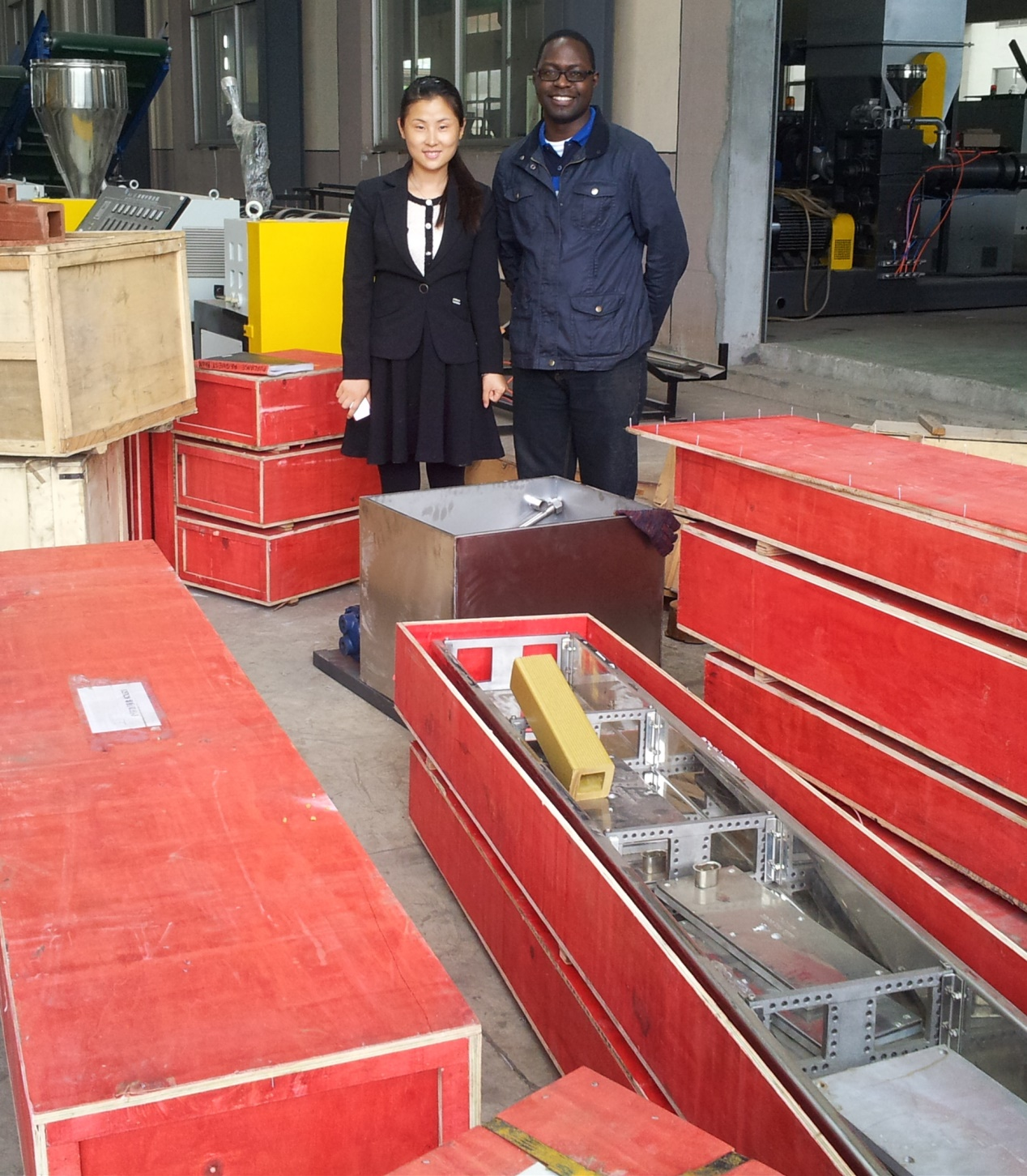

Double Screw Extruder WPC Profile machine

PVC /WPC making machine can produce all kinds of profile, for example, window, door and door frame, pallet, cladding of outdoor wall, facility of outside park, floor etc. Output profile is Wood Plastic Composite(WPC) or Plastic UPVC.

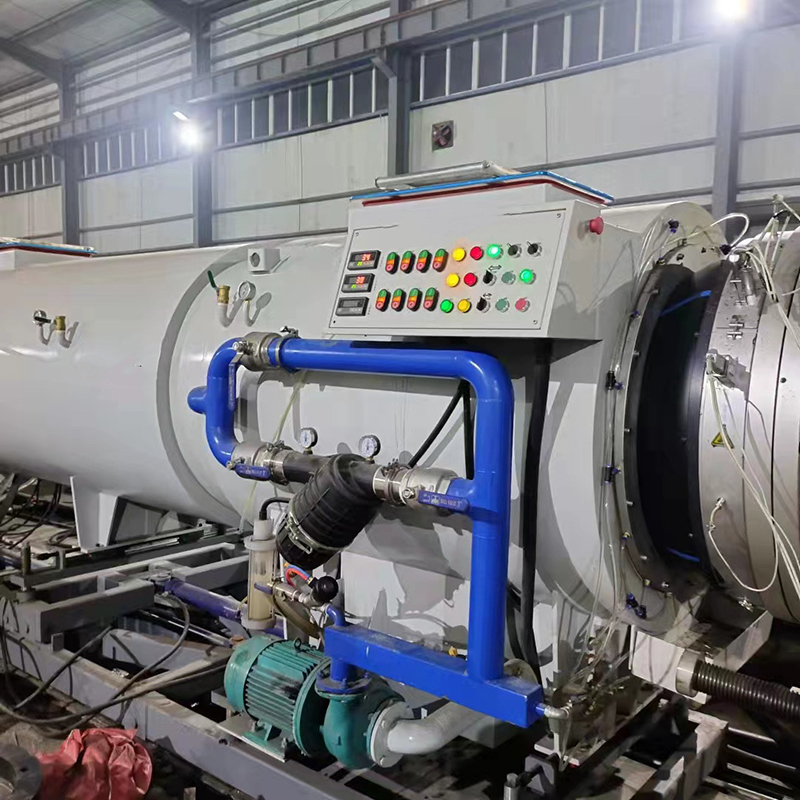

MAIN TECHNICAL PARAMETERS:

| Type | YF180 | YF240 | YF300 |

| Vacuum degree (map) | -0.08~-0.09 | -0.08~-0.09 | -0.08~-0.09 |

| Center distance of T type dies mounting groove (mm) | 320 | 320 | 460 |

| Height of die mounting base (mm) | 890~1100 | 890~1100 | 890~1100 |

| Move distance of vacuum forming machine (mm) | 5000 | 6000 | 6000 |

| Hauling speed (m/min) | 0.3~7.8 | 0.1~5 | 0.1~5 |

| Hauling force (kN) | 7.5 | 30 | 35 |

| Effective hauling length (mm) | 1.2 | 1.8 | 1.8 |

| Width of holding bolck (mm) | 180 | 240 | 300 |

| Pedrail open degree (mm) | 110 | 140 | 160 |

| Sawing linear veiocity (m/s) | 58.6 | 58.6 | 58.6 |

| Max Saeable section (mm) | 180*65 | 240*65 | 300*80 |

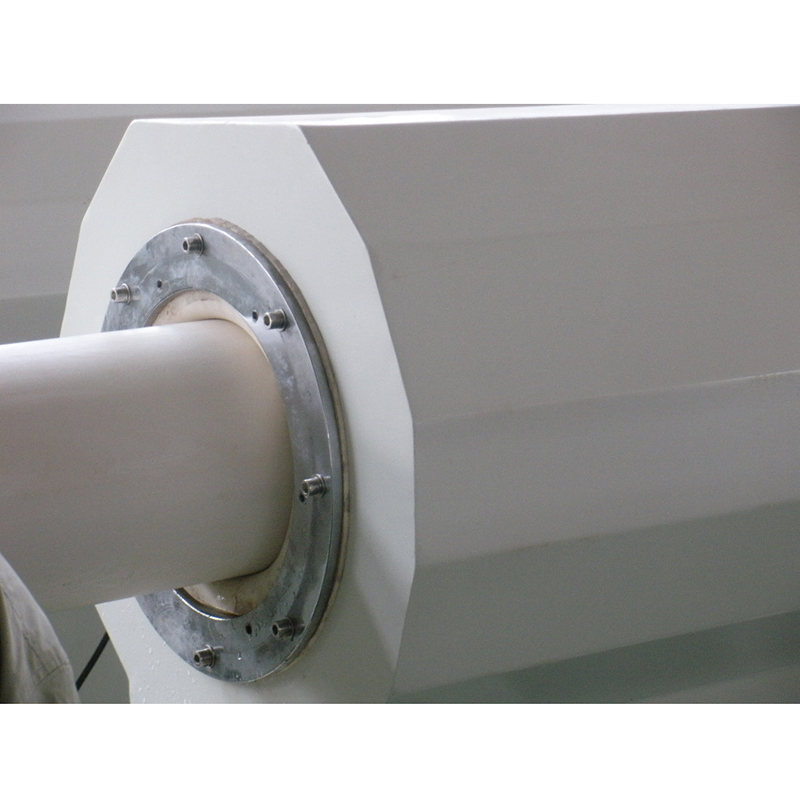

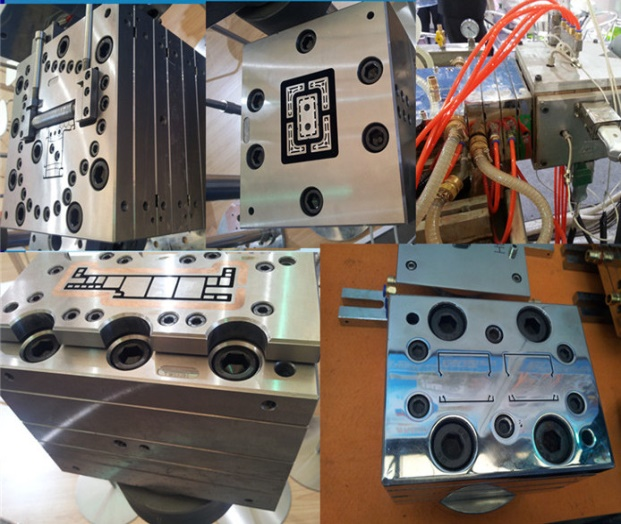

Die head

• 3Cr13/3Cr17 material; •Complete set include extrusion die head, calibrator and cooling tank; • Apply to soft PVC, rigid PVC, soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

Embossing machine--off line type (we also have online type)

Uses: This machine is applied to emboss wood grain pattern on the surface of WPC board, wood board, composite board, PVC board and so on.

(Note: you can choose different embossing rollers from our wood grain collection to do different wood grain.)

Applications:

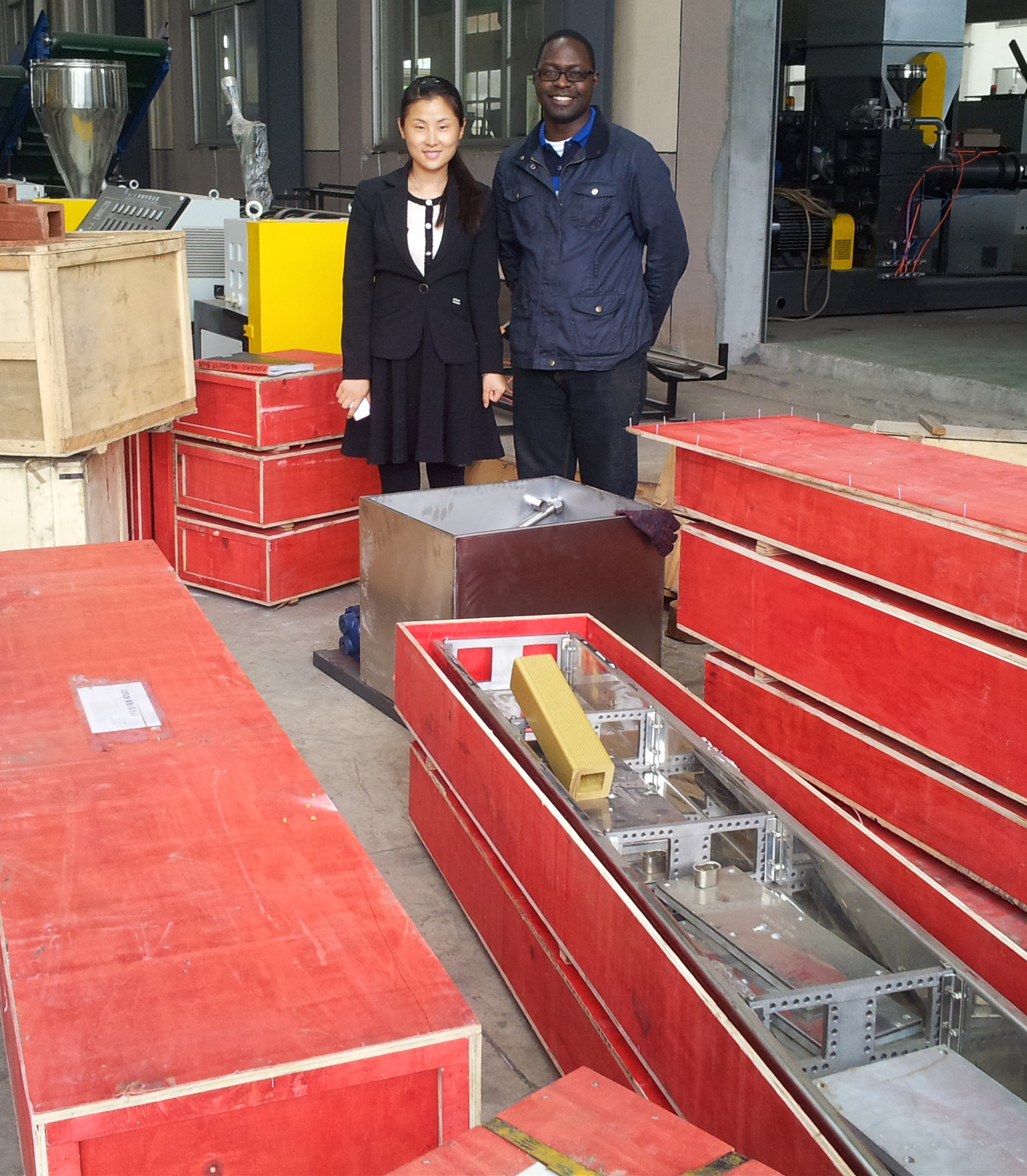

This line is used to produce wood plastic foamed wide door plate and windowsill plate, and the final products of this line collect the advantages of plastic and wood, which has not only the appearance of natural wood, moreover they overcome the shortages of natural products. The final products of this line are featured by antisepsis, damp proof, anti-worm, high stability and anti-cracking, etc