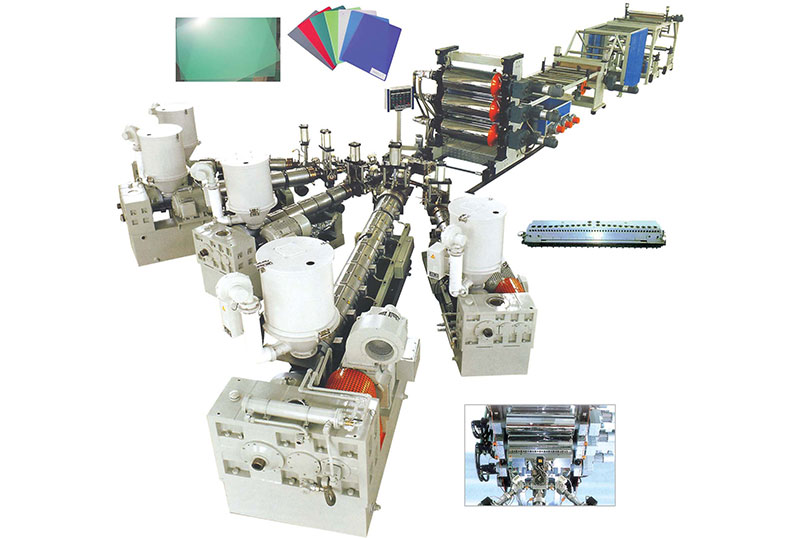

Conical Twin Screw Plastic Extrusion Machine Pvc Foam Board Extrusion Line

Plastic Board Machine we are professional do :

PVC foam board machine/WPC foam board machine

We specializes in manufacturing PVC WPC foam board machine , WPC floor machine, SPC floor machine, PVC wall panel board machine, PVC free foaming board machine. This line can produce furniture board,construction board,advertising board and flooring sheet and so on. JIASHANG has been specialized in researching, developing and manufacturing PVC sheet and board machine for more than 10 years. So far, it has occupied a large proportion of the market share of similar equipment at home and aboard.The development of pvc foam board extrusion line witness our company's growth and strength. It is also our biggest and strongest shining point in this area.We are also one of the biggest exporters in China. We have exported more than 20 countries.

MAIN PARAMETERS OF PVC FOAM BOARD

Width: 1220mm

Length: 2440mm

Thickness: 2-30mm

Density: 0.38-0.8g/cm3

Output: 550-600kg/h or 700kg/h, it depends on the choice of extruder. Also can do co-extrusion sheet/board machine .

ENVIRONMENTAL CONDITION

| Location | Indoors |

| Power Supply | No dangerous area |

| Humidity | ≤95% |

| Temperature | 0-40ºC |

| Power | 3-phase, 380V, 50Hz |

| Total Installed Power | <300KW |

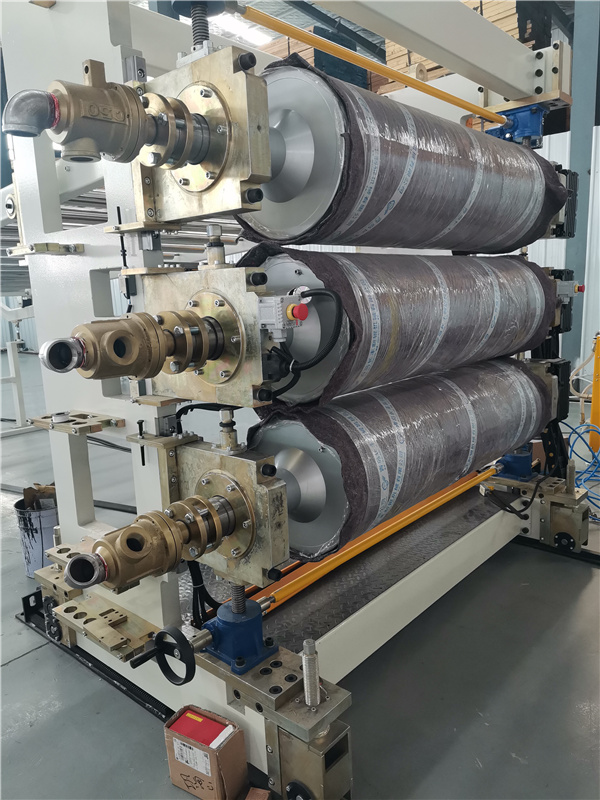

| Cooling Water | ≤25ºC ≥0.3MPa, outdoor water tank: 20-30m3, water circulated with production line |

| Compressed air | 0.3 m³ /min, >0.5MPa, Equipped with 5.5-7.5kw air compressor |

| Production Line Dimension | 25m*3m*3m |

Flow chart

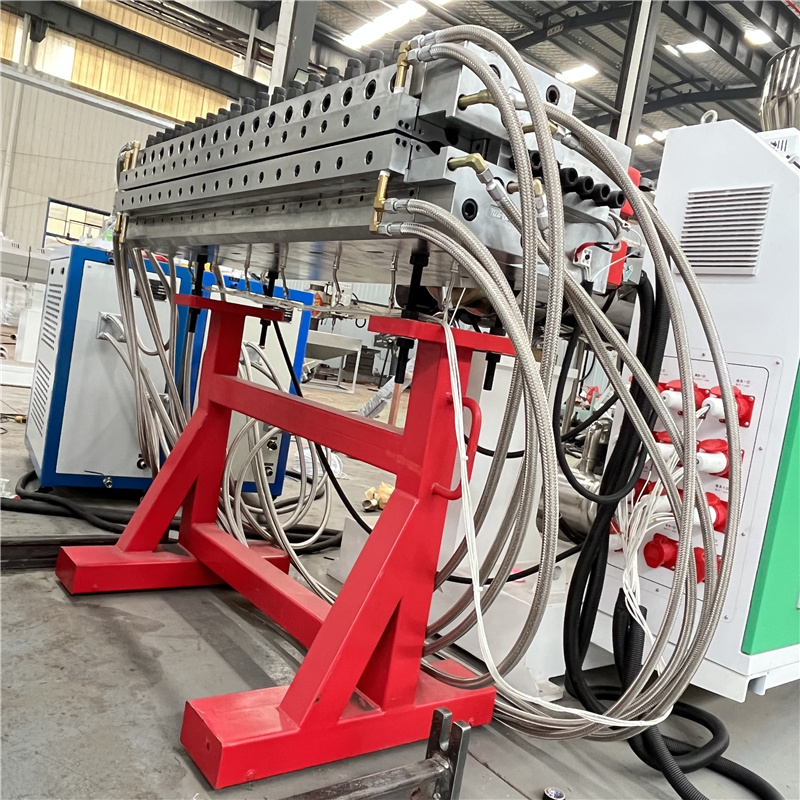

Mixer→Loader→Extruder→Mould→Calibration platform→Cooling bracket→Hauling machine→Cutting machine(With dust collector)→Stacker

→Packing→Crusher(for waste material) →Pulverizer(For recycled material)

Q1: Your company is a trading company or a machine manufacturer?

A1:Our company is a plastic machinery manufacturer which is engaged into this trade more than 10 years.As a manufacturer,we could supply our machine,service,technical support and maintenance directly and it is more convenient.

Q2:How to get an accurate offer?

A2:Because our offer and technical specification is associated with your final product and requested capacity,we will choose the right model of extruder and mould after understanding all the information,then we could supply our plan.We could fully exchange information by Email,whatsapp or wechat.

Q3:Where is your factory and which port is the nearest to your factory?

A3:My factory is in Qingdao city,Shandong Province and it would take about 25minutes from our factory to Qingdao jiaodong Airport.

The nearest port is Qingdao port.

Q4:How long is the delivery time?

A4:Generally it will take 35-45days.

Q5:Could you send your engineers to our factory?

A5:Yes,we will send our engineers to your factory for installation,commissioning and training after machines arrive at your factory.In addition,if you need our engineers available in the future,we also could send our engineers.