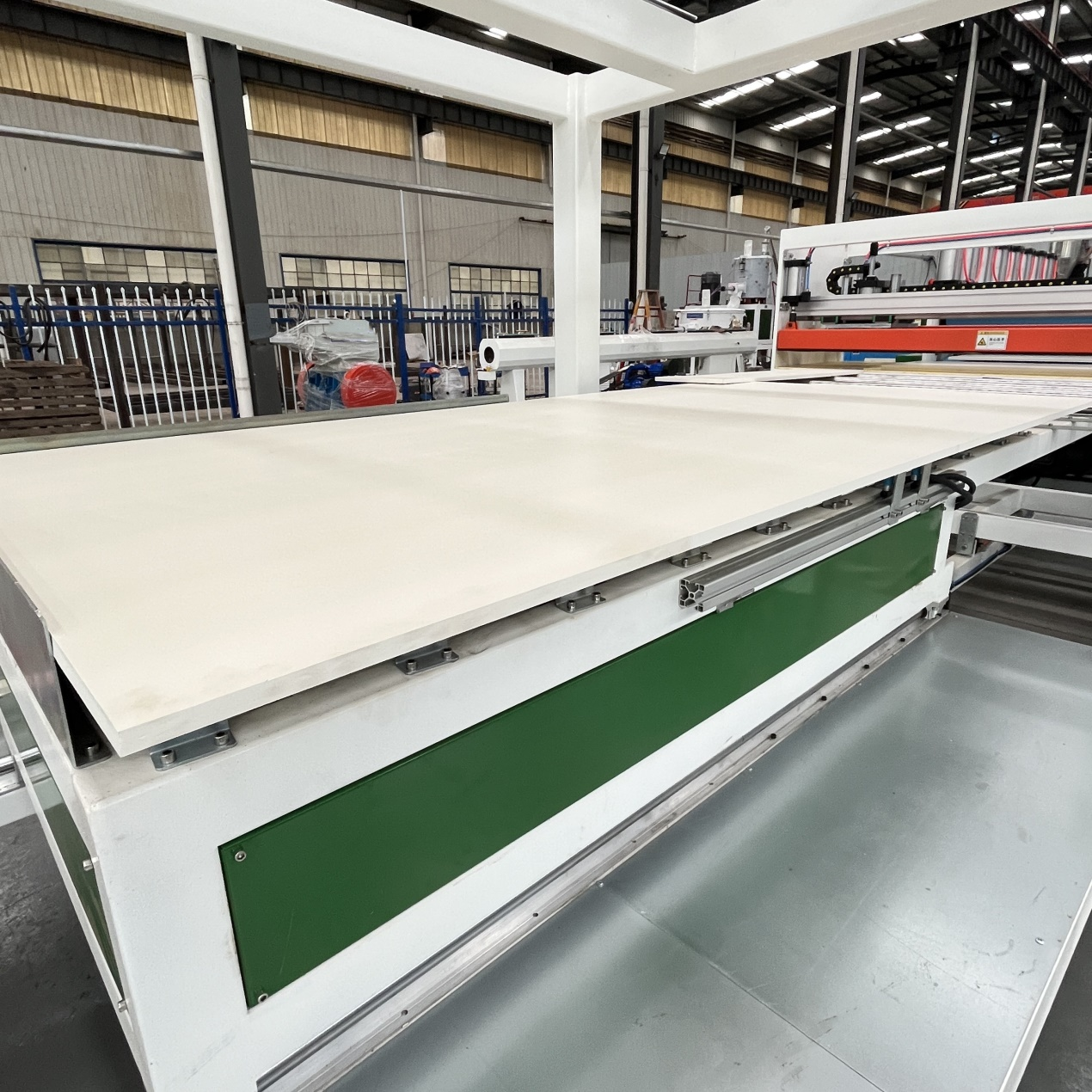

automatic board robot stacker

WPC/PVC Foam Board Production Line--Stacker

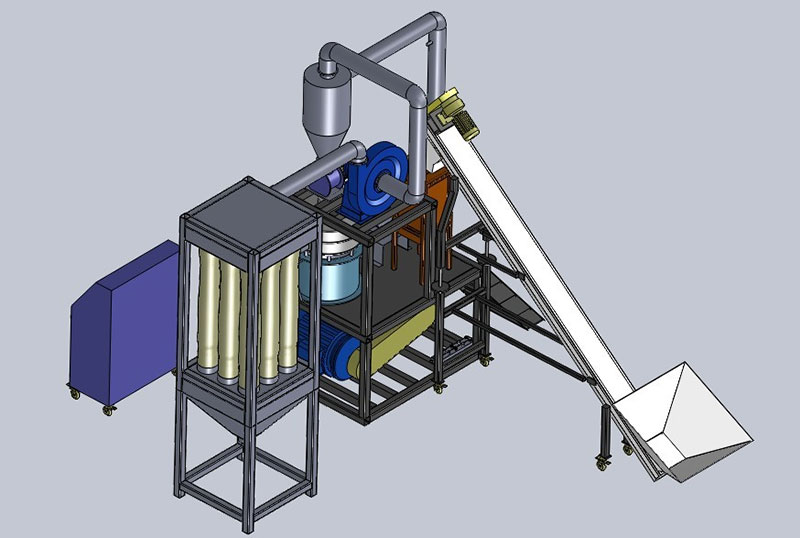

main parameter configuration of special plate splicer for plate

1.Overall dimension of equipment: 6500 * 1890 * 2600 (5000) mm;The height of the saw is 1150mm-980 mm, which can be adjusted with the center of the saw, and can be connected with the cutting table by the bracket;

2.Electrical system:

Operation mode: PLC + touch screen, brand: Xinje

Low voltage apparatus: Omron, Siemens, Schneider;

3. Alignment mode of plate conveying: stainless steel idler, idler Φ 60mm, number of idler 18, idler drive is cycloid reducer controlled by frequency converter, reducer model is bwy0-9-0.75kw, frequency converter brand: DELTA

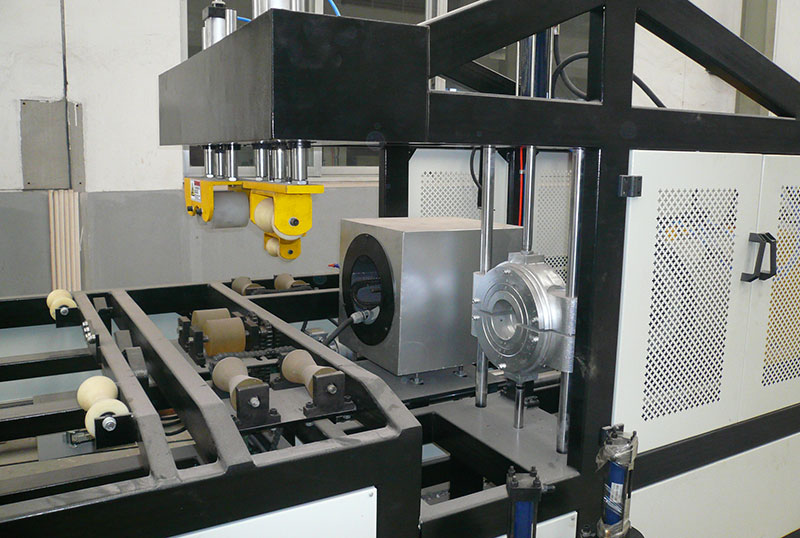

4、 Lifting system: variable frequency speed regulating brake motor drive, RV Reducer rubber roller guide vertical lifting, motor power 1.0kw, reducer rv63-25, frequency converter brand: Xinje;

5、 Translation system: servo motor drive RV Reducer, reducer rv63-10, servo motor model: 80st-0.75kw, brand: Xinje

6、 Plate grabbing method: vacuum suction cup, number of suction cups: 10;

7、 Maximum stacking height: 1400mm;

8、 Maximum grasping weight: 50kg;

9 Maximum operating speed: 50s / time;

10、 Suitable plate size: 1000-3200mmx1220mm;

11、 Roller :15-19pcs

12.Conveyer motor:0.75kw

13. Lifting mode: Variable frequency speed control brake motor