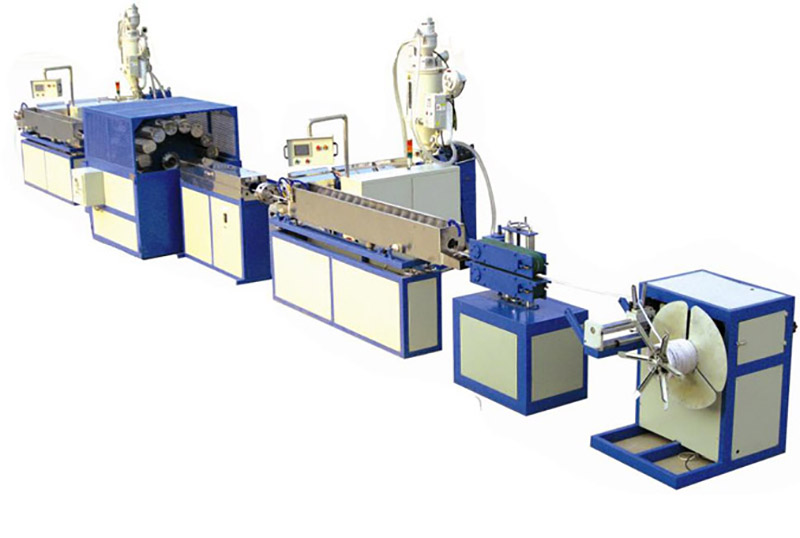

50-110mm PVC pipe production line

Detail specification of each machine in the line

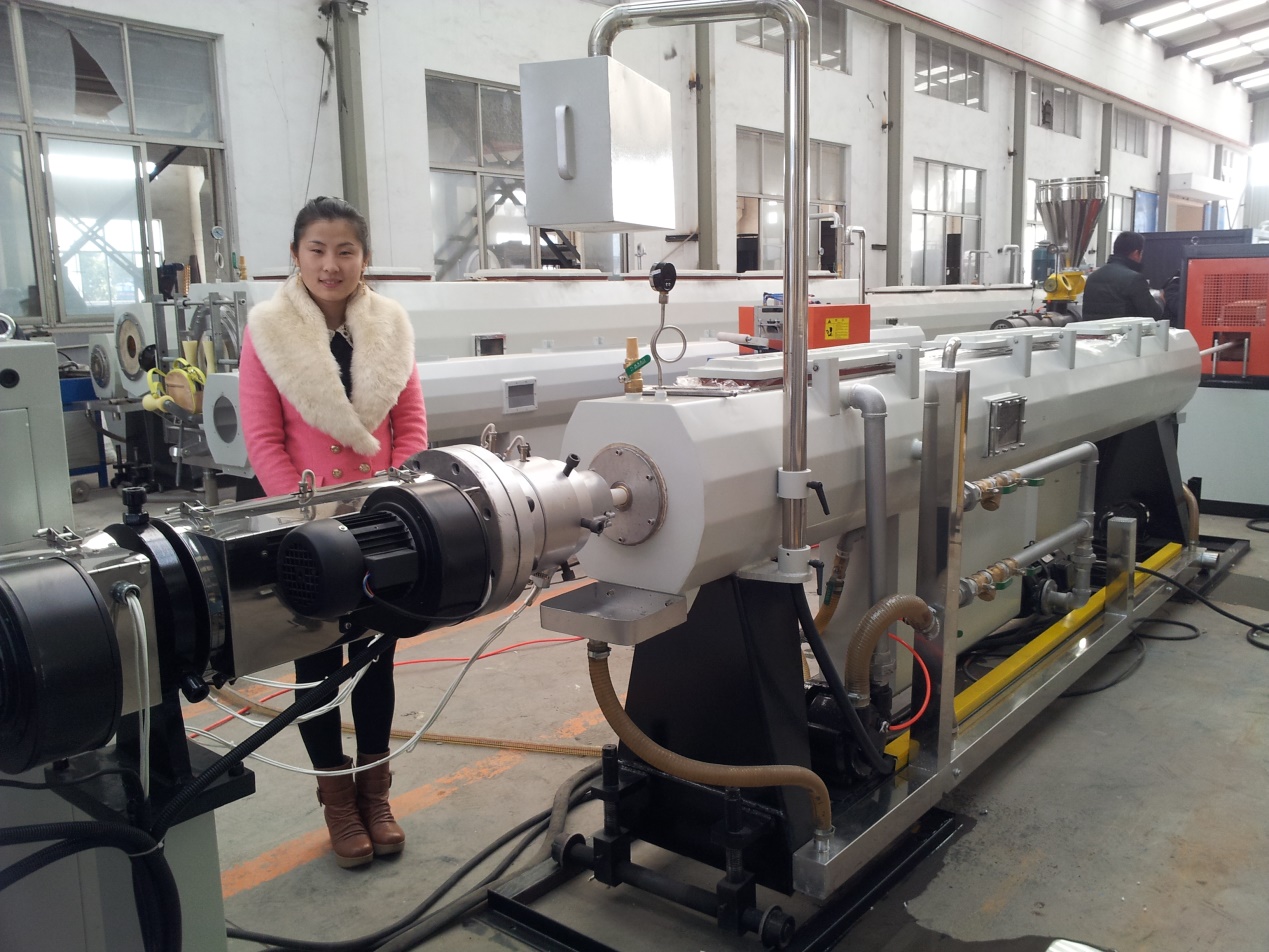

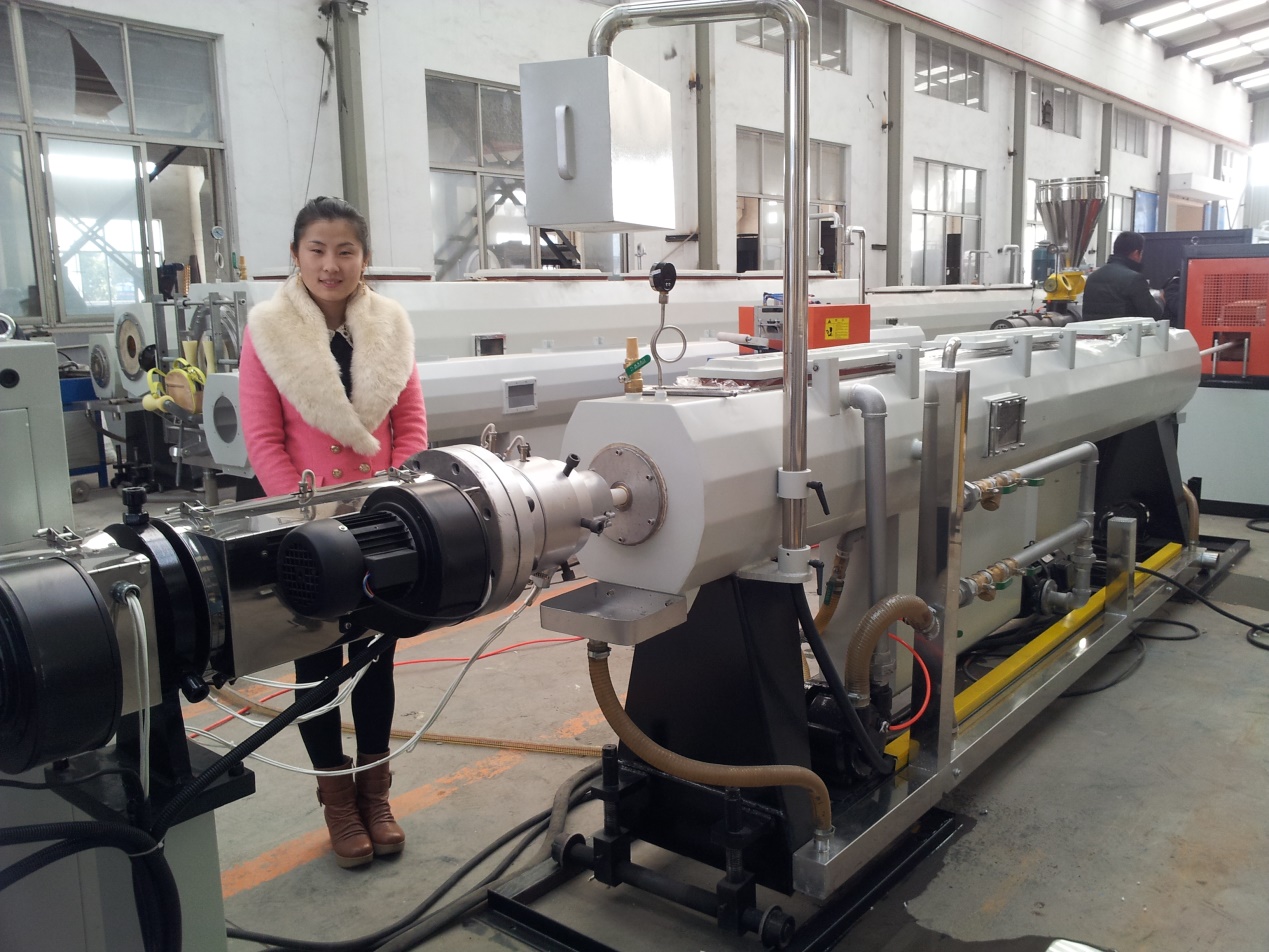

1. SJSZ65/132 Conical Double Screw Extruder

| Screw and barrel | |||

| 1 | Screw Diameter | mm | ¢65/132 |

| 2 | Screw Length | mm | 1440 |

| 3 | Screw rotation speed | r/min | 1-38 |

| 4 | Material of Screw and Barrel | / | 38CrMoAlA Nitrogen Treatment, polishing |

| 5 | Depth of nitration case | mm | 0.6-0.8mm |

| 6 | Barrel Heating | / | Casting Aluminum Heater |

| 7 | Heating zones | / | 4zone |

| 8 | Heating Power | kw | 24 |

| 9 | Cooling power | kw | 0.25kw*3 |

| 10 | Cooling | / | blower cooling |

| 11 | Screw core temperature control | / | Automatic cycle temperature control |

| 12 | Screw core temperature adjusting | / | By circle conduction oil |

| Gear box | |||

| 1 | Gear | / | Hard tooth face |

| 2 | Brand of gear box | / | Jiangyin gear box company |

| 3 | Shaft | / | NSK of Japan |

| 4 | Safeguard of screw | / | With Safeguard device for screw |

| Feeding device | |||

| 1 | Fixed quantity Feeding system | / | 1.1KW, screw fixed-quantity feeding |

| 2 | Speed control way | / | Frequency inverter |

| Motor and electric system | |||

| 1 | Motor Power | KW | 37(AC motor, Siemens brand) |

| 2 | Speed adjusting mode | / | Variable frequency conversion |

| 3 | Output Capacity | Kg/h | 180-250 |

| 4 | Vacuum exhaust system | / | 1.5kw, vacuum pump |

| 5 | PLC touch screen | / | Siemens brand |

| 6 | Frequency inverter | / | ABB |

| 7 | AC contactor | / | Schneider |

| 8 | Voltage | / | According to requirement |

| 9 | Extruder axis height | mm | 1000 |

| Self protective system | |||

| 1. Over current protective of motor | |||

| 2. Over pressure protective of screw. | |||

Moulds for50-110mm PVC pipe

Hauling off Machine (50-110mm)

Planet cutting machine(50-110mm)