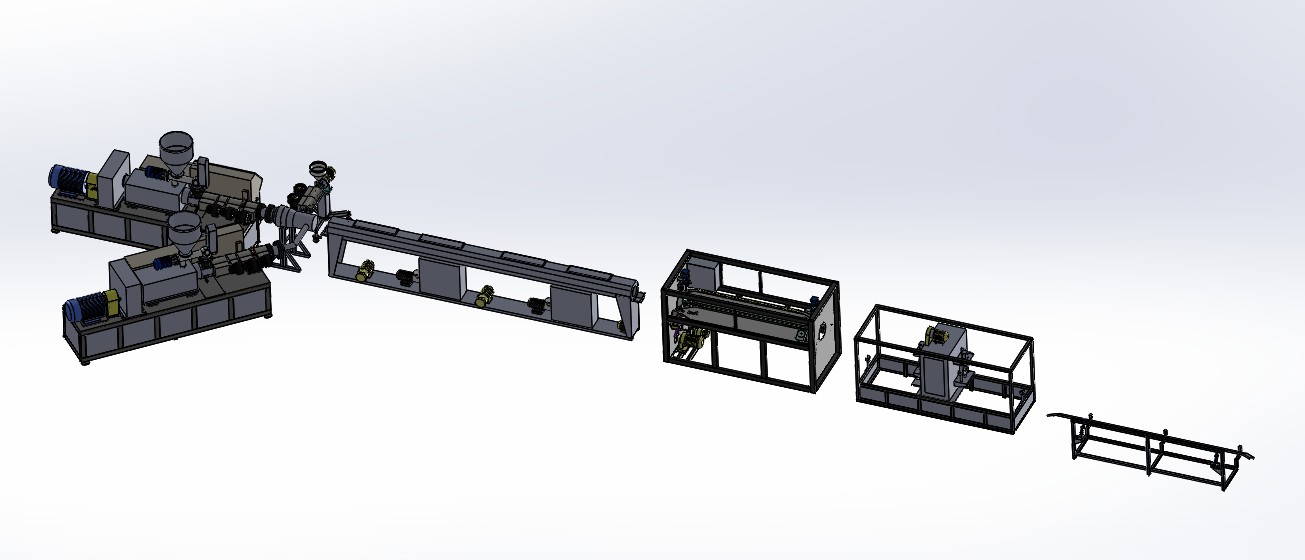

16―110mm PE pipe production line

Main technical parameter

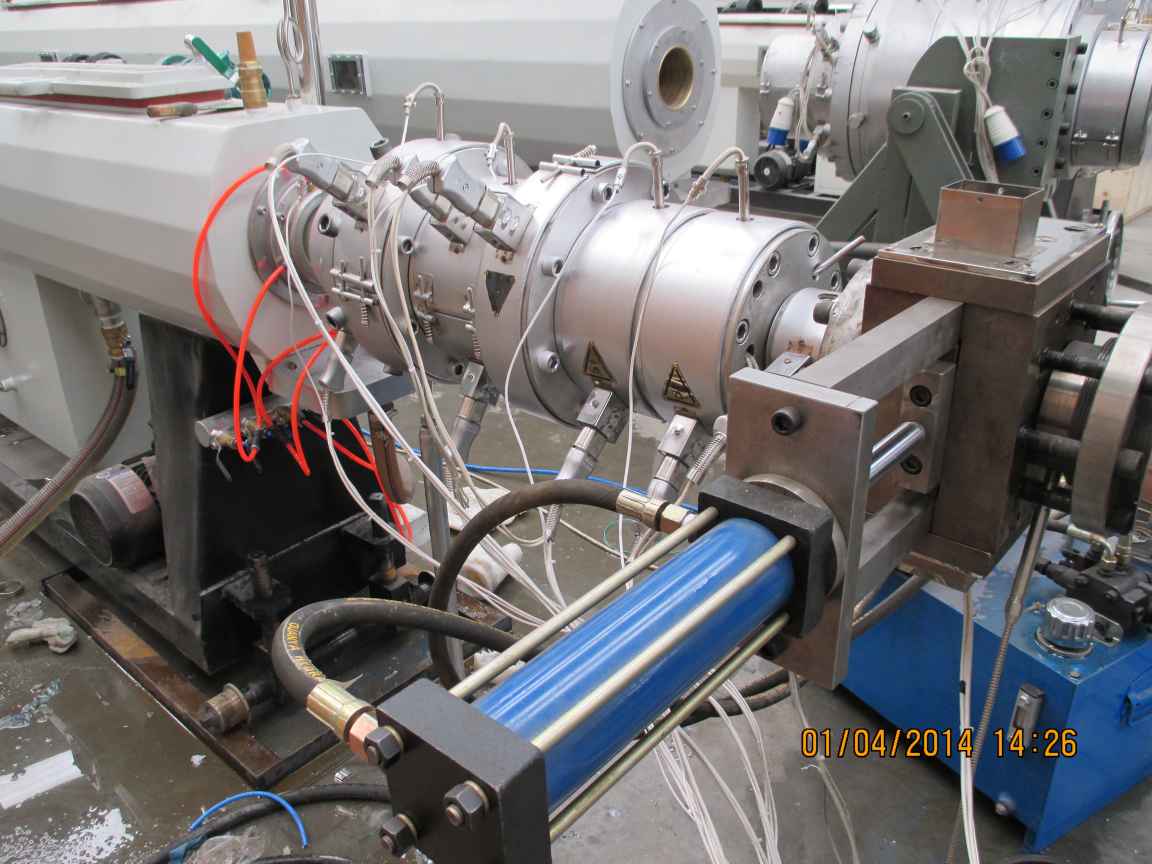

Single-screw extruder SJ75/33

| Diameter of screw | 75 mm |

| Rotating speed of screw | 1-100 r/min |

| L/D | 33:1 |

| Power of main motor | 75 kw |

| Heating power of barrel | 30 kw |

| Output | 180-240 kg/h |

| Center height | 1000mm |

| Weight | 3500kg |

| Dimension | 4000x1500x1500mm |

| Timing way of mainframe | Frequency conversion |

| Temperature control of barrel | Heating: cast aluminum heaterCooling : 5 sections wind cooling |

| Material of screw and barrel | 38CrMoAlA Nitrided on surface 0.4~0.7mmRigidity: above 700 HV |

| Gearbox | Hard tooth face |

| Main motor frequency controller | ABB |

| Temperature controller | OMRON |

| AC controller | Schneider |

| Thermal overload relay | Schneider |

| Switch | DELIXI |

Single-screw extruder (So-extruder, used to make lines on the pipe) SJ25/25

| Diameter of screw | 25mm |

| L/D | 25:1 |

| Power of main motor | 1.5 kw |

| Rotating speed of screw | 0-30r/min |

| Heating power | 3 kw |

| Extrusion capacity | 8 kg/h |

| Center height | 1000mm |

| Weight | 250kg |

| Dimension | 1600 x 1000 x 1500mm |

| Timing way of mainframe | Frequency conversion |

| Temperature control of barrel | Heating: cast aluminum heaterCooling : .2 sections wind cooling |

| Material of screw and barrel | 38CrMoAlA Nitrided on surface |

| Drive way | Hard tooth face gearbox |

| Material of screw and barrel | 38CrMoAlA Azotizing on surface |

| Drive way | Hard tooth face gearbox |

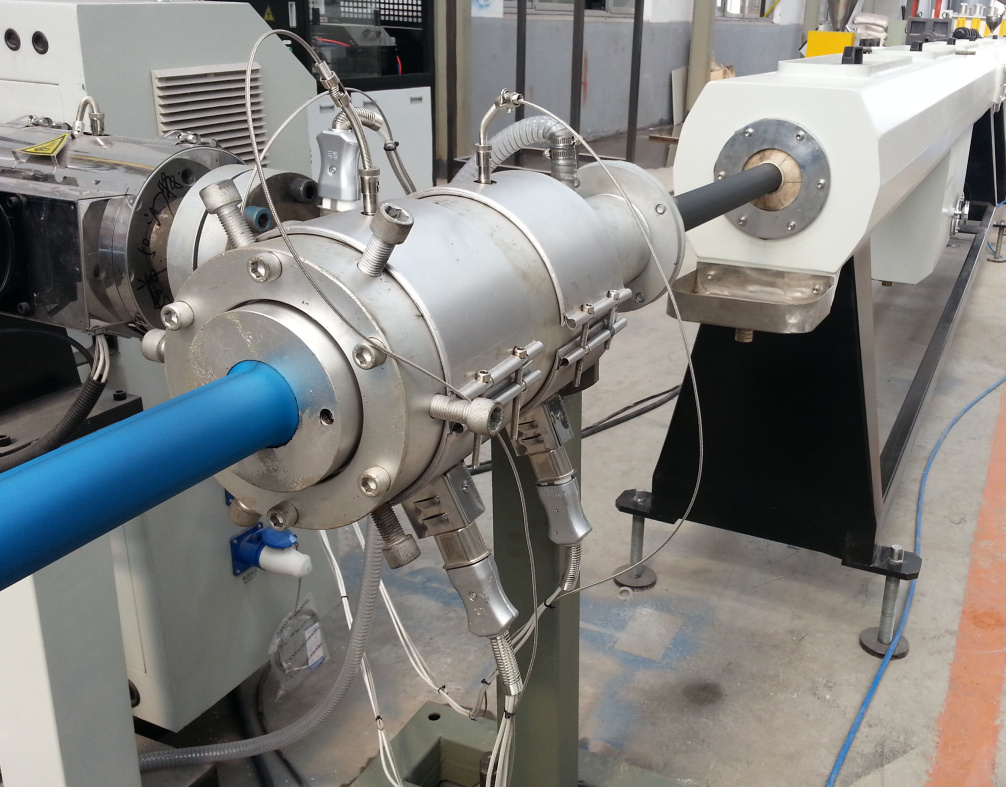

Mould

| Material | Forge steel |

| Specification | ∮16-∮110mm |

- Vacuum forming machine

| Power of vacuum pump motor | 3kw x 2 water-ring vacuum pump |

| Power of water pump | 3kw x 2 |

| Power of lengthways motor | 1.1 kw cycloid |

| Material | Stainless steel |

| Position and method of cooling spray | 4 sets spray-pouring cooling |

| Material and quantity of muzzle | ABS x 200 pcs. |

| Motion range of forward and backward | ±500mm, motor drive |

| Up-down adjusting range | ±80mm, by manual |

| Dimension | 9000 x 450 x 1400 mm |

| Weight | 1400kg |

Spraying & Cooling tank

| Method of cooling spray | Sprayer |

| Motor power of the water pump | 3kw |

| Material of the nozzle | ABS x 200pcs. |

| Figure dimension | 6000 x 650 x 1400 mm |

Caterpillar haul- off machine 1set

| Max .speed of hauling | 0-8 m/min |

| Haul-off range | ∮16 -∮110 mm |

| Motor power of hauling | 3 kw |

| Effective length of pedrail | 1500 |

| Adjusting mode of hauling motor | Frequency conversion |

| Center height mm | 1000 |

| Figure dimension mm | 1800 x 800 x 1600 mm |

| Air pressure MPa | ≥0.6 |

Dust free cutting

| Range of cutting mm | ∮20-∮110mm |

| Motor power of cutting | 2.2 kw |

| Air pressure | ≥0.6 MPa |

| Figure dimension | 2000 x 1200 x 1600 mm |

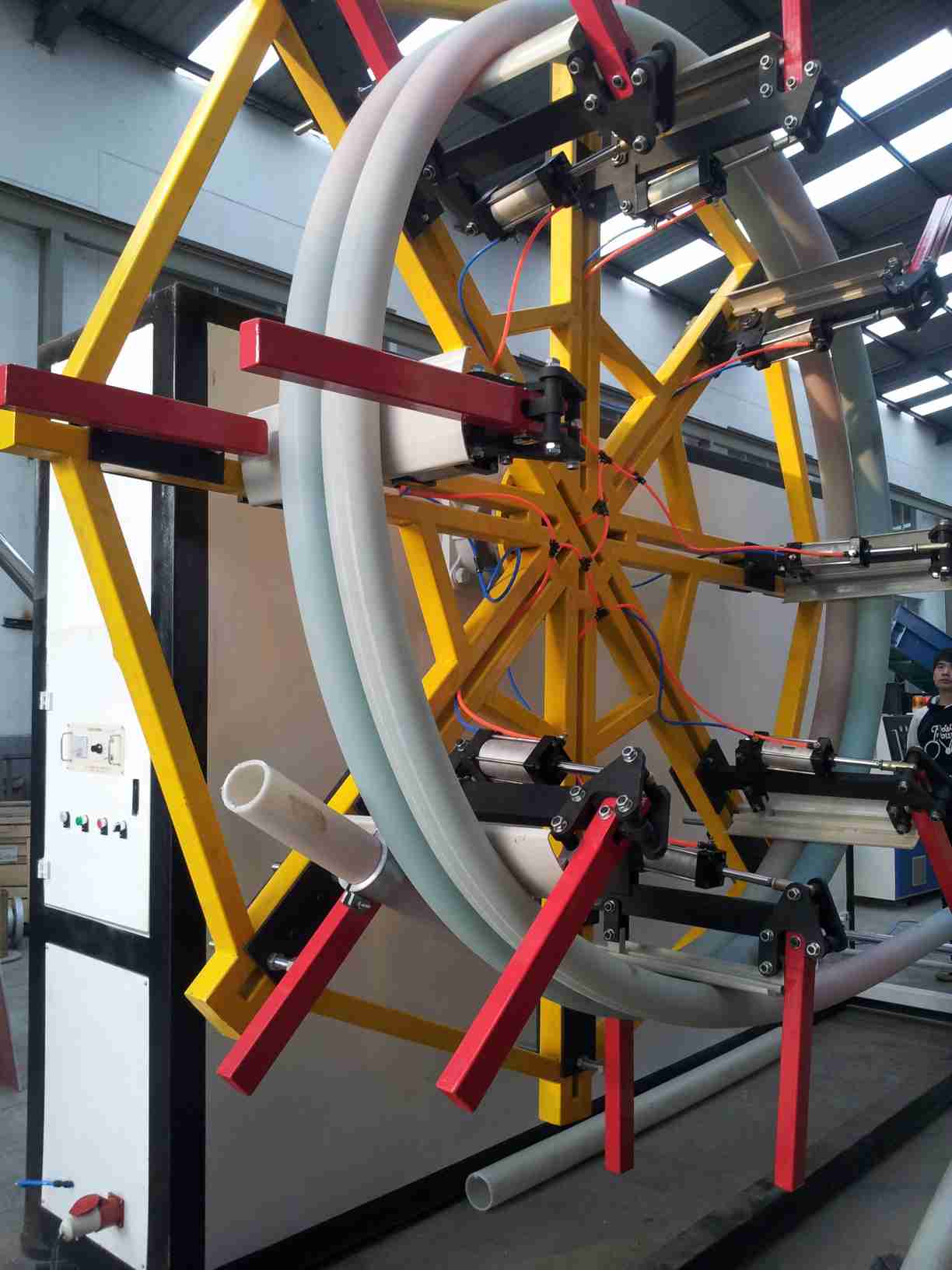

stacker or winder

Automatic loader ZJ 400

| Max. wind pressure | 13000 pa |

| Max. air volume | 2.8m3/min |

| Power of motor | 1.5kw |

| Rotating speed of motor | 2800 r/min |

| Transportation capacity | 400kg/h |

| Volume of aspirating hopper | 15 L |

| Inter diameter of transfer soft tube | 40mm |

| Inter diameter of aspirating soft tube | 50mm |

| Method of loading | Vacuum aspirating |

| Weight | 90kg |

Hopper dryer STG-U500

| Total volume | 500L |

| Heating power | 18 kw |

| Loading capacity | 300kg |

| Blower power | 0.55 kw |

| Material | Stainless steel |

| Temperature adjusting | Electron temperature adjuster |

| Weight | 240 kg |

| Dimension | 2000 x 850 x 2200 mm |

Application

HDPE gas pipe making machine PE plastic pipe extruder

1.City water pipe network system

2.Urban and rural drinking water pipe line.

3.Landscaping water supply and Sewage discharge pipes network

4.Agricultural irrigation pipe.